The basics of crusher maintenance ~ primary and secondary

Schmidt's top 10 cone crusher maintenance tips. • It is no surprise the first tip is doing comprehensive daily inspections.

Learn MoreGyratory Crusher Failure Modes | AMP Maintenance

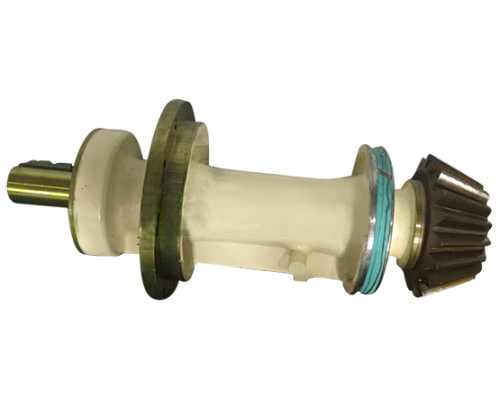

19/1/ · Possible failure modes related to: 1) Lubrication -- gears and bearings. 2) Hydraulics -- controls. 3) Assembly -- tolerances, fit and tightness. 4) Installation -- fastener correct strength

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience. thyssenkrupp gyratory crushers represent today's state-of-the-art. They are designed for high throughput rates and high crushing ratios at low operating and maintenance costs. Maintenance friendly design

Learn MoreWhat is a Gyratory Crusher | Quarrying & Aggregates

It is difficult to repair and maintain, and the repair cost and the cost of wear parts are high. The high fuselage of the gyratory crusher results in high infrastructure costs such as foundations and workshops. Generally, aerial cranes are required to facilitate maintenance. Application of

Learn MoreGyratory crushers - thyssenkrupp

They are designed for high performance and, at the same time, cost-effective operation,. i.e. low servicing and maintenance costs. When it comes to crushing

Learn MoreCrusher Maintenance - WOMP

by the crusher manufacturer. “Predictive maintenance — monitoring the condition of the crusher while it is in operation — uses tools such as lubricating oil temperature and pressure sensors, crusher coast downtime, no-load head spin, lube oil analysis reports, crusher drive motor power draw readings, vibration sensor readings and completed daily

Learn MoreGyratory Crusher Services I Service - thyssenkrupp Mining Technologies

Stop your crusher, start the disassembling Replace the installed shells by preassembled spare shells Assemble the crusher - go back in operation Your added value Increased availability Increased safety Decreased labor Shortage of downtime by up to 50 %

Learn More2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing

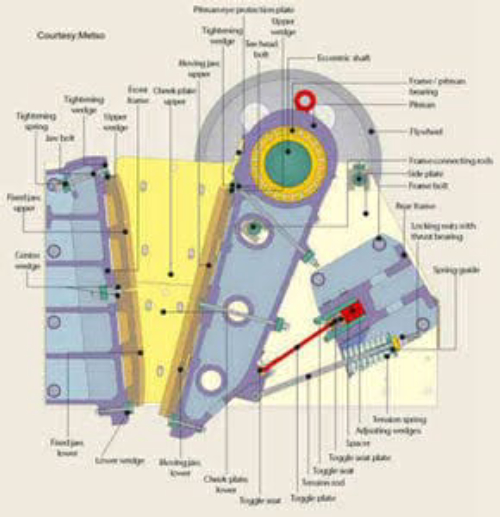

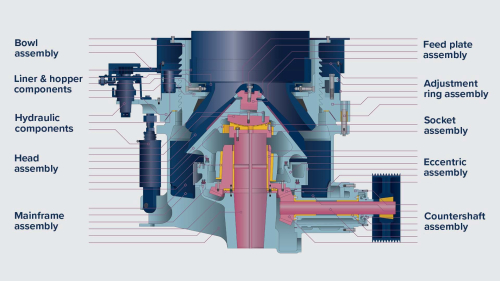

The parameters used in the basic design of a gyratory crusher are nip angle, feed rate, feed opening, closed-side setting, work index, and horsepower. The combination of the nip angle, feed opening, and closed-side setting determine the length of the crushing chamber and indirectly the length of the main shaft.

Learn MoreGyratory Crushers - Dorr-Oliver Eimco - PDF Catalogs

This entire Gyratory Crusher is engineered from the ground up with Safety and Maintenance in mind. The feature that distinguishes the "TS" design from other Gyratory r Crushers is * that the "TS" machine is designed to be Serviced & Maintained from an Overhead Crane.

Learn MoreUnderstanding three different types of crusher maintenance

Implementing a preventive maintenance program is the best method of keeping a crusher in good operating condition for a long period. Preventive

Learn MoreCrushing, screening, feeding and plant solutions

Maintenance. The TS gyratory crusher is distinguished from other gyratory crushers by its revolutionary design which allows major service and maintenance

Learn MoreHOPPER CLEANING OF GYRATORY CONE CRUSHER 4 SCHEDULED

9/1/2022 · HOPPER CLEANING OF GYRATORY CONE CRUSHER FOR SCHEDULED MAINTENANCE OF RING SEALINGPlease subscribe#technical_info_fe2o3#crusher#crushing#miningengine

Learn MorePrimary Gyratory Crusher Maintenance - Crushing, Screening

My questions are regarding to maintenance of the primary gyratory crushers. Does anybody know any kind of sensor to monitoring head spin of the main shaft

Learn MoreCrusher Re-Build | Crusher Repairs - CMS Cepcor

From Routine Crusher Maintenance To Full Crusher Re-Builds Standard repair procedure involves stripping the jaw crusher, cone crusher or impactor to

Learn MoreGyratory Crushers - Mineral Processing & Metallurgy

17/2/ · In the Gyratory crusher, the original discharge setting may be maintained for the life of a single set of alloy crushing surfaces with only one resetting of concaves. Raising the

Learn Morefuctions of gyratory crusher

the functions of a gyratory crusher. The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions It is designed so that you can easily access and remove the eccentric assembly bushings and hydraulic piston.

Learn MoreGyratory Crusher (TS) for harsh environments

The Gyratory Crusher TS is distinguished from other gyratory crushers by its revolutionary design which allows you to easily and safely perform major service and maintenance functions. It is designed so that you can easily access and remove the eccentric assembly, bushings and hydraulic piston through the top of the crusher, hence the name

Learn MoreGyratory Crusher Failure Modes | AMP Maintenance Forums

Anyway, I was wondering if anyone can assist with failure modes of Gyratory Crushers. The model we have on site is a KB 63 - 89.

Learn MoreTLC for Primary Crushers | E & MJ

A gyratory crusher is a significant investment for any mine. Poor maintenance can result in unplanned shutdowns for repairs, premature failures and

Learn MoreJaw crusher maintenance - Pit & Quarry

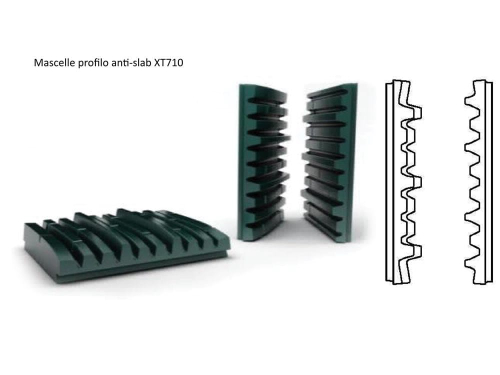

Check jaw dies daily, making sure bolts are kept tight. Check cheek plates for any excessive wear that may affect the mainframe of the jaw.

Learn MoreWhat Are the Differences Between The 7 Types of Crushers?

20/7/2022 · If you only want to crush more raw material with more than 1000t/h and no special demands on final particle shape, you can choose gyratory crusher. Because it can be fed with two sides, which greatly reduces crushing time and improve crushing ratio thus saving lots of energy cost. Note: If ton/hr<161.7 (gape in meters)∧2, use a jaw crusher.

Learn MorePrimary gyratory crusher parts - Outotec

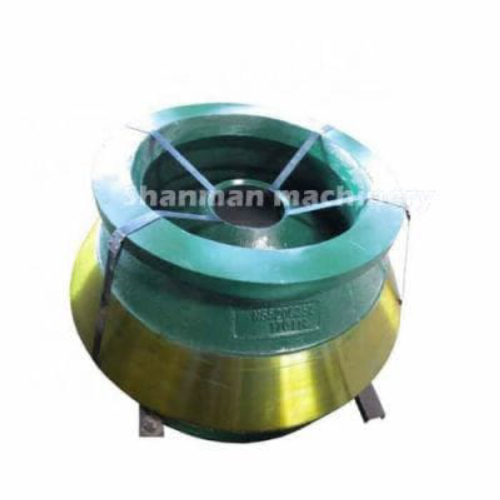

A crusher mantle or a set of concave segments with a longer wear life do not need to be replaced as often. You will need fewer per year but also have fewer maintenance shutdowns. This means that you save the cost of performing a change-out.

Learn MoreCommon faults and maintenance items of gyratory crusher

29/8/2022 · The minor repair period of the gyratory crusher is generally 15 to 20 days, which is mainly determined by the wear of some wear-resistant parts in the equipment. The work content of the minor repair is mainly to wear, maintain and lubricate the dustproof device, suspension device, nylon rod and related supporting parts of the crusher.

Learn MoreImprove safety and maintenance with our gyratory tooling

Don’t rely any longer on the industry standard method for tightening and loosening the gyratory crusher headnut. We combined proven technology and innovation to create a headnut tool system design that eliminates your safety concerns while at

Learn MoreConstruction, Working and Maintenance of Crushers for

As compared to the jaw crusher, where it only crushes when the swing jaw moves towards the fixed jaw, with its rotational action, the gyratory crusher is always

Learn MoreSafer Faster Smarter Gyratory Crusher Maintenance

The biggest single cause of crusher downtime is mantle and concave change outs and GET events are generally well within the top 5.

Learn MoreGyratory crusher upgrades - Outotec

Go from MK I to MK nXt with our Superior primary gyratory crushers upgrades. Mix and match to suit your goals: better production, reliability & maintenance.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

Inspection and maintenance of other parts Check whether the discharge port is blocked, remove the blockage in time, and keep the discharge unobstructed. Check whether the V-belt is loose. If it is too loose, you need tight it because loose belt will cause slippage. Whether the eccentric shaft is blocked.

Learn MoreConstruction Working and Maintenance of Crushers for

Gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). The feed material should be at

Learn MoreGyratory Crusher

why choose our Gyratory crusher: Efficient and Intelligent Production. High Output Yet, Low Crushing Costs. Simpler Operation and Maintenance. Sufficient Supply of Spare Parts, Worry-Free Operation. Strong Adaptability, Applicable for Severe Crushing Conditions. Able to Work Continuously under High Intensity, It has longer service life.

Learn MorePDF Construction Working and Maintenance of Crushers for Crushing Bulk ...PDF

Gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). The feed material should be at least 15 to 20% smaller than the width of the feed opening. Gyratory crusher's discharge setting is referred to as the Open Side Setting (OSS).

Learn More

Leave A Reply