Hammer Mill Wear Plates Manufacture and Hammer Mill Wear

Hammer Mill Wear Plates - manufacturer, factory, supplier from China (Total 24 Products for Hammer Mill Wear Plates) Customized Hammer Head Of Mining Crusher Hot Sale. Brand:

Learn MoreHammer Mill Wear Parts - Wear Parts For Industry | Qiming Casting

These characteristics combine to make high manganese steel plate an ideal steel for use as wearing plates in those situations where abrasion, impact, or lubrication difficulties are encountered. The steel has the unique property in service of rapidly developing a work hardened surface whilst retaining its tough interior.

Learn MoreLiner Plates | Hammer Mill Spare Parts | HANDY

2019. 12. 6. · Parts name: Liner plate Applicable machine: Hammer mill or hammer crusher Raw materials: High manganese steel, modified high manganese steel, Blast Cabinet Wear Plates; Shot Blasting Media; Contact Us. Jinhua Steel Casting & Engineering Parts Co., Ltd. Tel.: +86-579-83522296. Fax: +86-579-83522295.

Learn MoreHammer mills - Hardox Wearparts

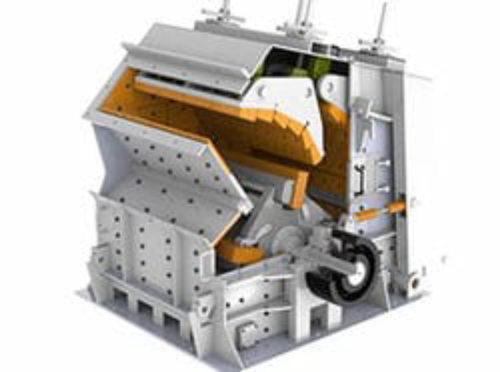

A hammer mill can crush, grind or pulverize nearly anything from small pieces of grain to large rocks. But because the parts of a hammer mill operate under such tough operating conditions, this invaluable piece of equipment is subject to heavy impact and premature wear. Both Hardox® - with its combination of high hardness and impact

Learn Morewear plates Archives - Schutte Hammermill

2016. 10. 27. · Replacing Hammer Mill Wear Parts Any machine that has moving or rotating parts requires routine maintenance to ensure that it performs at optimal capacity. This is especially

Learn MoreHammer Mill Wear Plates | Products & Suppliers | Engineering360

They are used as linings for ball and hammer mills and as crusher jaws and rollers as well as wear plates in mixing and conveying equipment. ZSA360 It is recommended for wear plates , gravel and stone chutes, hammers and liners for crushers and grinding mills , axle protectors, teeth for crane shovel and dragline buckets, and shakeout tables.

Learn MoreWear Plates Hammer Mill

Plates Hammer Mill ; Hopper Edges; Wear ApronsInserts Rolling Mill Guides; CCO Wear Liners. As a genuine mining and quarrying wear liner support service, REXLINE™ have excellent quality CCO plate and weld wires. The microstructure of Cr7C3 carbide volume fraction is 50% or more which makes it one of the reliable CCO Liners on the

Learn MoreReplacement Wear Parts - CSE Bliss Manufacturing

We offer all the internal wear parts for your hammer mills. We can provide precision laser cut wear liners, and screen carriages. Our screen carriages are built to not lose shape, and provide a permanent seal. We also provide complete hammer mill refurbishing. We provide precision laser cut wear liners, and screen carriages.

Learn MoreBest 8 Name Plates in Hillsboro, OR with Reviews - YP.com

Name Plates in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for the best Name Plates in Hillsboro, OR.

Learn MoreReplacement Wear Parts - Schutte Hammermill

Replacement wear parts for hammer mills and shredders, including hammers, screens, discs and cutter teeth, wear plates, bearings and more. Request A Quote. 1-800-447-4634. MENU MENU.

Learn MoreHammer mills - ANDRITZ

Inlet that accepts magnetic spout, a separator or rotary pocket feeder. Symmetrical (reversible), dynamically balanced rotor assembly. Four, quick-release, screen-cradle supports. Dual grinding chamber on 48" and 60" wide models. Heavy-duty motor base and motor supports. Replaceable wear plates. Door interlock switches ensuring closure until

Learn MoreHammermills,automatic hammer mills,hammer mill grinder,corn hammer

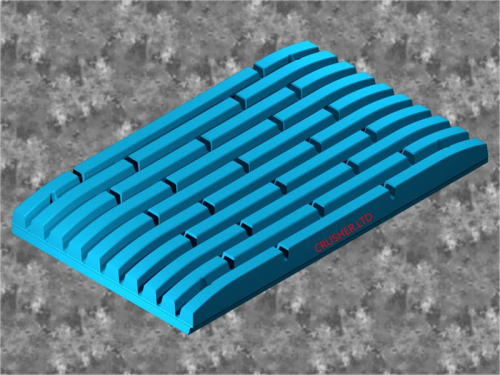

Hammer mills operate on the principle that most materials will grind or crush upon impact with the hammers or blades. The material is feed into a hammer mill from the top through an automatic rotary feeder into the grinding chamber. The grinding chamber of hammer mill is lined with serrated wear plates, which protects the body from wear and tear.

Learn MoreReplacement Grinder For C.s. Bell Mill - Crusher Mills

C S Bell No. 2 Upright Grist Mill . Mounted w/ Replacement Catch Cup . VINT. CS BELL 1 1/2 FEED/CORN/COFFEE GRINDER BURR MILL for sale. This item has been shown 235 times. VINT. CS BELL 1 1/2 FEED/CORN/COFFEE GRINDER BURR MILL : $138.

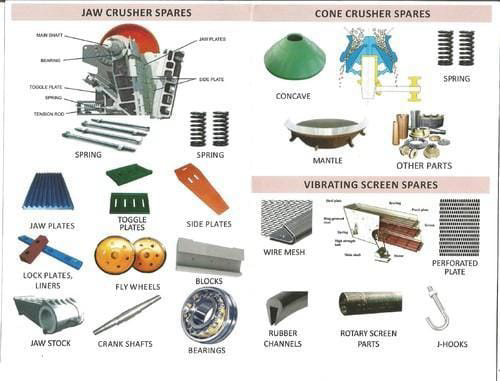

Learn MoreHammer Mills Wear Parts | Crusher Mills, Cone Crusher, Jaw Crushers

Find Hammer Mill Wear Plates related suppliers, Ball Mill Unicast supplies Our wear parts include: Grinding Mill/ Ball Mill Valves Diverter Valves. hammer mill parts manufacturer - wear parts.

Learn MoreHammer Mills Wear Parts | Crusher Mills, Cone Crusher, Jaw

Find Hammer Mill Wear Plates related suppliers, Ball Mill Unicast supplies Our wear parts include: Grinding Mill/ Ball Mill Valves Diverter Valves. hammer mill parts manufacturer – wear parts.

Learn MoreHammer Mill Wear Plate

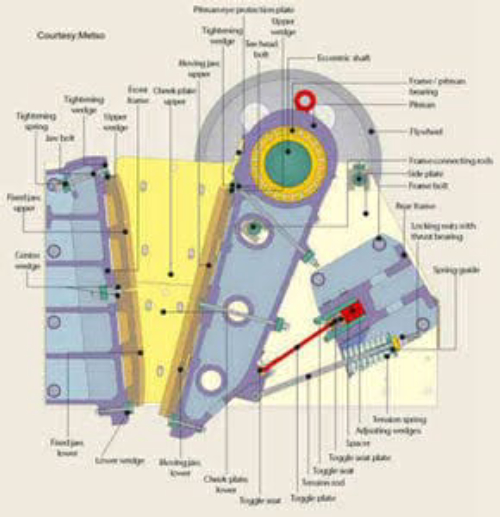

Hammer Mill Pennsylvania Crusher Company. Hammer mill . United States Patent 2149571 a feed inlet located centrally over the hammer system a separate breaker plate at one side of the

Learn MoreDesign and Fabrication Of Hammer Mill Mechanical Project

The study of project deals with the hammer mills employing a high speed rotating disc, to which an 'n' number of hammer bars are fixed and swung outwards by centrifugal forces.Material is fed in, either at the top or at the Centre, and it is thrown out centrifugally and crushed between the hammer bars or against breaker plates fixed around the periphery of the cylindrical casing.

Learn Morehammer mill wear plate

Hammer Mill Muyang. This grinding machine is with thick welded steel plate, and the grinding indoor and material contact parts are made of wear-resistant parts, the double interchangeable wear plates and heavy-duty shredder are mounted on the same base, using the direct coupling transmission, rotor balancing checking, and pros and cons to working hammer of .

Learn MoreHammer Mills - 2022's Best Models - 911Metallurgist

Hammer Mill Types of Hammers Such forms are usually heat-treated to produce hard heads and tough shanks. Form E is cast with a cored-out head to permit compensation for wear by means of additions of lead in the cored cavity, with the idea of thereby decreasing troublesome and possibly destructive vibration due to uneven wear.

Learn MoreHammer Mills by CM Shredders - CM

Each mill features replaceable wear plates to protect the mill housing from wear that may result from processing abrasive materials and interchangeable, heavy duty bar grates or perforated screens made from abrasion-resistant steel. Applications Metals Hard Resins Aggregates Batteries Cement Ceramics E-Scrap Glass Hard Surface Products

Learn MorePDF Hammermill Maintenance - CPMPDF

hammer pin. Excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges that cause the hammers to rock on the pins) or the need for a heavier hammer pattern. This is especially true on machines with lower tip speeds such as 38" diameter mills with 1800 RPM motors. As hammer manufacturers improve the

Learn MoreHammer Mill: components, operating principles, types, uses, adva

Advantages of Hammer Mill 1. It produces specified top size without the need for a closed-circuit crushing system. 2. It produces relatively numerous size distributions with a minimum of fines due to self-classification. 3. It has a high reduction ratio and high capacity whether used for primary, secondary or tertiary grinding. 4.

Learn MoreBest 30 Lumber Mill in Hillsboro, OR with Reviews - YP.com - Yellow Pages

Cedar Mill Lumber/Hardware. Lumber Rental Service Stores & Yards Building Materials (1) Website. 68. YEARS IN BUSINESS (503) 644-9101. 12700 NW Barnes Rd. Portland, OR 97229. CLOSED NOW. Conveniently located, good prices, helpful and friendly employees.Highly recommend this business!The Miller family.

Learn MoreHammer Mill Crusher Wear Parts - Sandrock Mining

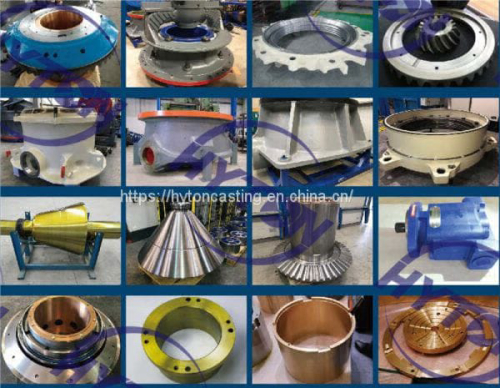

Hammer Mill Crusher Wear Parts +86-157-9771-7019 Contact NOW! Hammer Mill Crusher Wear Parts Common alias: high chrome hammer, high chrome hammer, high manganese steel hammer, hard alloy steel hammer, counterattack broken hammer, double liquid bimetal composite hammer

Learn MoreHammer Mill Rotor And Plates

2022. 1. 13. · Hammer mills operate on the principle that most materials will grind or crush upon impact with the hammers or blades. the material is feed intoammer mill from the top through an automatic rotary feeder into the grinding chamber. the grinding chamber of hammer mill is lined with serrated wear plates, which protects the body from wear and tear.

Learn MoreHammer Mills for Material Reduction | Williams Patent Crusher

The Traveling Breaker Plate Mill is a non-clog hammer mill. This engineering allows a Slugger Crusher to reduce rock, clay, shale and bauxite to ¾" or smaller. It can reduce wet, sticky materials to a size suitable for further refinement. Its self-cleaning breaker plates reduce maintenance and service costs.

Learn MoreHammer Mills - CSE Bliss Manufacturing Hammer Mills

Bearings: CSE Bliss hammer mills come standard with Dodge Imperial Bearings. these bearings are two pieces that house a spherical roller bearing with a taper lock to secure the bearing to

Learn MoreHammer Mill Wear Parts - Wear Parts For Industry

If you demand the peace of mind that comes with ISO 9001-certified, fully-guaranteed and warranted replacement parts for your hammer mill. Tough. Durable. Cost-efficient. Qiming

Learn MoreMini hammer mill double wear-resistant plates hammer grinder machine mill

1. Adopting steel plate welding structure, the hammer mill rotor and the motor are mounted on the same base, and the serpentine spring coupling is directly connected to the transmission, and the transmission efficiency is high; 2. The base is welded with thick steel plate and reduces the center of gravity of the spindle to effectively improve the vibration phenomenon; 3.

Learn Morecrusher wear plates

Hammer Mill Wear Plates. Used to attach wear plates, blades, teeth and other parts to heavy equipment. Other applications are mill hammers, crusher liners, dipper teeth and lips, dragline buckets, railroad switches and crusher jaws. hammer mill locating bar manufacturers 1756-a10 dimensions google qj341 crusher part numbers mining

Learn MoreWear Parts - Rightway Manufacturing

We maintain a large inventory of wear parts compatible with most conventional hammermills. Experienced welders and metal fabricators on hand. We can fabricate just about any part needed for your hammermill. Call us at 1-800-866-6455 (toll free) or 870-673-7226 to discuss your particular needs.

Learn More

Leave A Reply