Hammer Mill Crusher & Grinder - Mineral Processing & Metallurgy

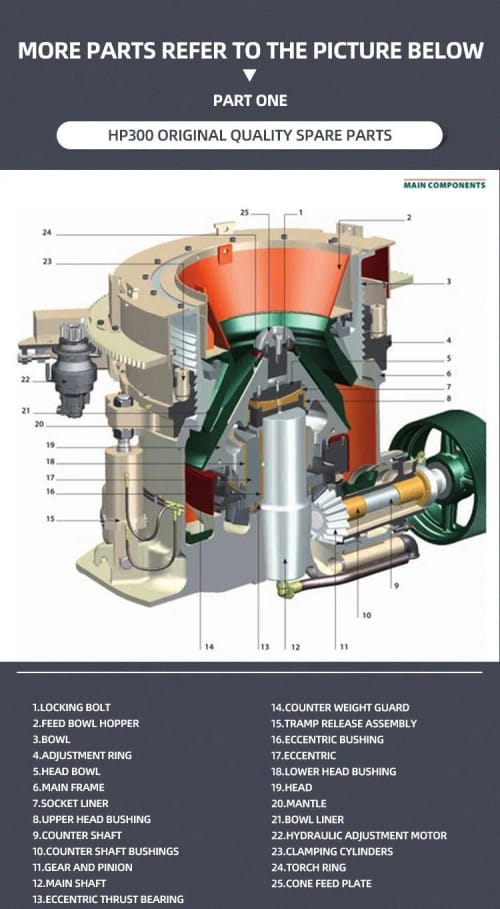

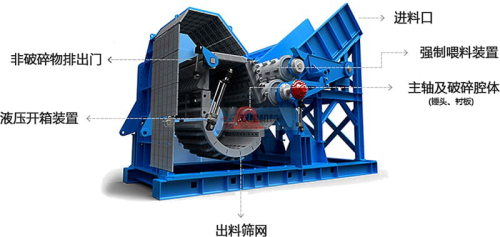

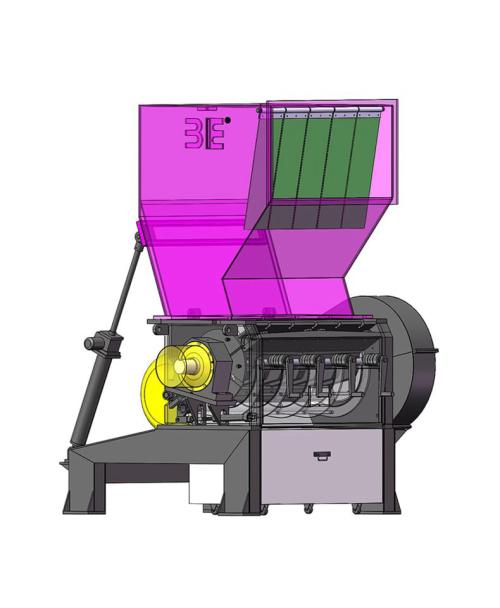

Hammer Mill Working Principle, The hammermill, fundamentally, is a simple mechanism. The "orthodox" machine comprises a box-like frame, or housing, a centrally disposed, horizontal-shaft rotating element (rotor) on which the hammers are mounted, and usually a set of circumferentially arranged grates in the lower part of the housing.

Learn Morehammer mill principle pdf

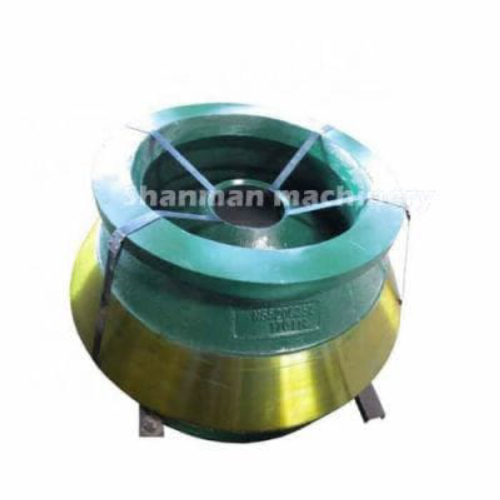

Hammer Mill Operating Principle. Operational Characteristics : The method of operation has a considerable effect upon the nature of the product. When minimum fines are a requirement, the hammer mill should always he operated in closed circuit with a screen, or screens; the circulating load should be fairly high; speed should be as low as is

Learn MorePDF Back to Basics Hammer Milling and Jet Milling Fundamentals - AIChEPDF

feeding (e.g., making metering into the mill difficult), grind-ing (e.g., plugging the hammer mill screen or blocking the air classifier of a jet mill), and collection (e.g., plugging the bag filters). There are two ways to grind sticky materials. The first solution is to dry the material prior to grinding, or dry and

Learn MoreHammer Milling and Jet Milling Fundamentals - AIChE

This article gives a detailed description of hammer mill and jet mill operation, and describes how to characterize the feed material and control product

Learn MoreBack to Basics Hammer Milling and Jet Milling

feeding (e.g., making metering into the mill difficult), grind-ing (e.g., plugging the hammer mill screen or blocking the air classifier of a jet mill), and collection (e.g., plugging the bag filters). There are two ways to grind sticky materials. The first solution is to dry the material prior to grinding, or dry and

Learn MoreOptimization Issues of a Hammer Mill Working Process Using

PDF | Our paper presents the hammer mill working process optimization problem destined for milling energetic biomass (MiscanthusGiganteus

Learn MoreHammer Mill Working Principle and Construction

The shaft is rotated at a high speed and centrifugal force causes the hammers to swing out radially. The material is beaten by the hammers around inside of the

Learn MorePellet Masters - Pellet Mills, Hammer Mills, and Grinders

STRUCTURE AND WORKING PRINCIPLES l, The hammer mill consists of three parts on the whole: feed hopper, grinding cell, winding system. 2.Production flow The raw material flows into the grinding cell by feeding hopper, and then is grinded to powder by rotary flake hammers' hitting. The rough powder and find powder all fly to the screen.

Learn MorePERFORMANCE EVALUATION OF A HAMMER MILL FOR

The results revealed that, the optimum operating conditions for both A and E mills were obtained at rotor speed of. 2100rpm, cobs feed rate of 0.2 ton/h and 9mm

Learn Moreindustrial applications of hammer mill

Hammer mills can resize solids, dry materials, fibrous material, slurries, etc. It is an essential equipment in micronization. 4. Hammer Mills Help to Improve Formulation or Dissolution In pharmaceutical, cosmetic and food processing industries, at times, mixing products require a large surface area. This is possible by reducing particle sizes.

Learn MoreHow Does a Hammer Mill Work?

How Does a Hammer Mill Work? Hammer mills work on the principle that most materials will crush, shatter or pulverize upon impact: The Process: • Material is fed into the mill’s chamber

Learn MoreImpact Crusher Working Principle - Mineral Processing & Metallurgy

Impact Crusher Working Principle. Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them. Impact crushing can be of two variations: gravity and dynamic. An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on

Learn MorePDF Prater G IOM Manual - Public HealthPDF

KEEParea around unit, drive and control station free of debris and obstacles. NEVERoperate unit without guards and all safety devices in position and functioning. ALWAYSallow unit to stop naturally. DO NOT attempt to artificially brake or slow motion of unit.

Learn MoreHammer Mill - Principle, Construction, Working, and Advantages

Advantages of Hammer Mill: Hammer mill is easy to install, operate, dismantle and clean up. It occupies less space and can be easily placed in one corner of the manufacturing area. Various grades of material can be handled using screens of different sizes. It is versatile, and speed and screens can rapidly change based on milling requirements.

Learn MoreDesign and Development of Hydraulic Power Hammer

work carried out in improving the design, construction and testing of hammer mill by addressing some lapses associated with the design and construction of the existing ones. These in Amesbury, Massachusetts in the USA. The principle of the power hammer is similar to the wheeling machine in that they both shape the metal[4]. Incorporation of

Learn Morehammer mill operating principle pdf - Sebocom Construction

Hammer mill must not be operated solo. At least two workers must be present when the mill is in use. Operators must wear eye and hearing protection as well as nuisance dust masks at all times when operating the mill. Operators must inform project leader when mill will be used. 2.

Learn MoreWorking of Hammer mill - Solution Pharmacy

The hammer mill operates on the principle of impact between rapidly moving hammers mounted on a rotor and powder.

Learn Morehammer mill principle pdf

the best hammer mill and process flow for your application OPERATING PRINCIPLE The grinding action of the hammer mill is caused by a combination of impact from the high tip speed of the free swinging hammers on the product, particle to particle impact and the cutting edge of the screens and breaker bars The product enters at the top

Learn MoreAKANA Hammer Mills - Crushing of Individual Products and

The hammer mills work according to the principle of crushing by multiple impacts. □ By means of the direct blow of the hammer mill beater on the.

Learn MoreStudy of Hammer mill and Ball mill

1. Hammer mills: In a hammer mill, swinging hammerheads are attached to a rotor that rotates at high speed inside a hardened casing. The hammer mill consists of a steel casing in which a

Learn MoreHammer Mills: Working Principle, Types and Application - Macawber India

This type of hammer mill is well-suited for lighter materials like paper, greenwood, biomass, etc. Gravity Discharge Industrial Hammer Mills: This hammer mill makes use of swinging hammers, mounted on a shaft. The process of particle size reduction takes place by the hammering application, plus via the particle-on-particle force.

Learn MoreHammer Mill: components, operating principles, types, uses, adva

Advantages of Hammer Mill, 1. It produces specified top size without the need for a closed-circuit crushing system. 2. It produces relatively numerous size distributions with a minimum of fines due to self-classification. 3. It has a high reduction ratio and high capacity whether used for primary, secondary or tertiary grinding. 4.

Learn MoreFactors affecting hammermill performance - CORE

Hammer design is an important factor in the design of e hammer mill. sd.ll is doing less work per unit weight of Material being reduced.

Learn MoreHammer Mill Working Principle Pdf Download

Hammer Mill Working Principle Pdf Download 25 operating principles figure 21 illustrates the basic operating principle of the prater full screen hammer mill the g series mill uses a

Learn MoreHammer Crusher Principle Pdf

Hammer mill working principle pdf Hammer crusher (hammer mill) are applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The crushing compressive strength of materials should not be in excess of 150Mpa. Get Price.

Learn MoreIntro to Size Reduction - HubSpot

Schutte-Buffalo Hammermill LLC How Does a Hammer Mill Work? Hammer mills operate on the basic principle that most materials will crush,.

Learn MoreHammer mill working principle pdf - Consuol Mining Machinery

Working principle of hammer mill pdf Posted at 07:16h in blog by admin Small hammer mills are often used to shred or crush materials into smaller pieces. The basic design of machines of this type involves a rotating shaft to which free-swinging hammers are attached. This equipment is enclosed in a drum which holds the materials to be pulverized

Learn MoreWorking Principle Of A Hammer Mill

Working principle of hammer mill pdf Posted at 07:16h in blog by admin Small hammer mills are often used to shred or crush materials into smaller pieces. The basic design of machines of this type involves a rotating shaft to which free-swinging hammers are attached. This equipment is enclosed in a drum which holds the materials to be pulverized.

Learn MoreHammer Mill - Principle, Construction, Working, and More - Soln Pharma

The working principle of the hammer mill is simple to understand. The principle is illustrated in Fig. 1 (a). It only requires choosing an appropriate motor, crushing hammers/knives and material to be crushed. It operates on the principle of impact between rapidly moving hammers mounted on the rotor and the stationary powder bed.

Learn MoreHammer Mill Working Principle Pdf

The Working Principle of Hammer Mills (Step-by-step Guide) A hammer mill is an essential machine in the pharmaceutical and food processing industries. You can use it to crush pulverize shred grind and reduce material to suitable sizes. Even though there are many types of hammer mills the working principle is still the same. Chat Online (PDF

Learn MorePDF Study of Hammer mill and Ball mill - courseware.cutm.ac.inPDF

1. Hammer mills: In a hammer mill, swinging hammerheads are attached to a rotor that rotates at high speed inside a hardened casing. The hammer mill consists of a steel casing in which a central shaft is enclosed to which a number of swinging hammers are attached. When the shaft is rotated the hammers swing out to a radial position.

Learn More

Leave A Reply