Choosing the right crusher - Buying Guides DirectIndustry

Although it is known for its ability to crush hard and abrasive ores and rocks, the cone crusher is better suited for secondary crushing. It is designed to crush pre-dimensioned materials, generally of 100 mm, 150 mm or 200 mm, and provide finished products of small dimensions. Advantages: Sturdy construction High productivity Easy adjustment

Learn MoreZI CONE | Crushing/Grinding | CO., LTD

MODEL AND CAPACITY · Note1. Capacity is based on the conditions that bulk density is 1.6 t/m3 (with feed size less than discharge setting not included) and that

Learn MoreHow much is A Cone Crusher? - Luoyang Dahua Crusher

10/08/2022 · Single cylinder cone crusher Multi-cylinder cone crusher Cone crusher advantages: 1. Reduce downtime Due to the safety device, it greatly reduces the downtime. At the same time, the body is a cast steel structure, and reinforcement bars are arranged in the heavy load parts. 2. High production efficiency

Learn MoreHow to distinguish between Cone Crusher and Gyratory Crusher?

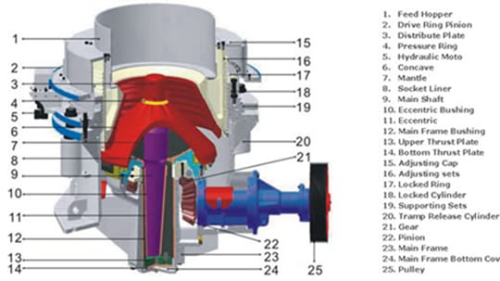

The two cones of the cone crusher are both gently inclined upright truncated cones, and in order to control the particle size of the discharged products, a parallel crushing area is set in the lower part of the crushing cavity, which results in different shapes of the crushing cavity.

Learn MoreCone Crushers - Astec

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market. Crushing Jaw Crushers

Learn MoreFULLTEXT01.pdf - DiVA portal

A review of modeling and control strategies for cone crushers in the concerning both particle shape and particle size distribution (such

Learn MoreCone Crusher - Mineral Processing & Metallurgy

This is usually specified by the metallurgist to give the desired crusher product discharge size. It can be checked by running the crusher empty, hanging a lead plug into the crusher bowl, and then removing it to measure the "gap". The gap is adjusted by rotating the bowl.

Learn MoreCone Or Gytory Crusher Particle Size

The cone crusher has a small particle size. Cone crusher is a common medium and fine crushing equipment on the market. It has a variety of cavity types, which can be selected according to needs. The conditioning method of the discharge port is relatively simple. The smaller discharge opening has a conditioning scale of 3-13mm, and sometimes

Learn MoreHow to Control the Discharge Size in Crushing Stone and Sand?

20/07/2022 · The following is a detailed description of the discharge control modes of jaw crusher, impact crusher, cone crusher, hammer crusher and roller crusher. Jaw crusher. It is a common coarse crusher. The size of the discharge port determines the size of the crushed stone and the production capacity of the equipment.

Learn MoreAMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Size is specified in terms of the gape and width, typically listed as gape x width. · Largest jaw crusher is 1600 x

Learn MoreCone crusher by SIEBTECHNIK TEMA. Crushing & milling

Technical specification ; Feed particle size, mm, 25, 25 ; Final particle size, mm, 2 - 10, 2 - 10.

Learn MoreMaximize your cone crusher productivity : Pit & Quarry

28/04/ · This will lead to inefficient use of connected crusher horsepower and a higher energy cost per ton of material crushed. 11. Limit the height from which the feed material

Learn MoreCone Crusher Sizes | Crusher Mills, Cone Crusher, Jaw Crushers

automax 1000 cone crusher max feed size – Grinding Mill China. OPS Screening & Crushing Equipment. Jaques World Class 42×30 Jaw Chamber. 650mm max feed size. up to 500T per hour. Gulin Finlay C-1540 Cone Crusher Automax 1000 .

Learn MoreCone Crushers | McLanahan

Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine. A general rule of thumb for applying Cone Crushers is the reduction ratio. A crusher with coarse style liners would typically have a 6:1 reduction ratio.

Learn MoreFAQ Of Cone Crusher - JXSC Mine

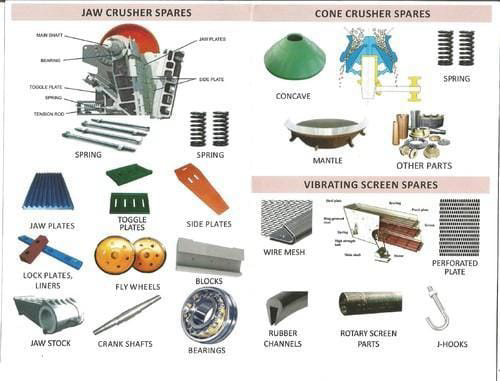

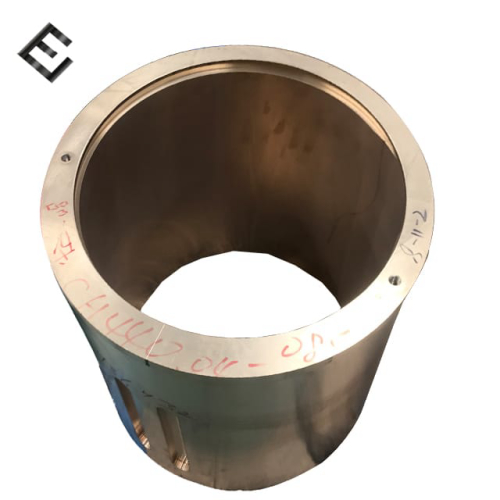

The liner as the easily damaged parts of the cone crusher, if it was evenly worn down to about 2.5cm, we should consider replacing it. Because the liner made of manganeses will crack when it about 1.6-1.9cm thick. Then causing the lining plate to

Learn MoreJaw Crusher Explained - saVRee

Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws. For example, a 32 x 54 sized jaw crusher will

Learn MoreROADRUNNER CONE CRUSHER - heavy equipment - by owner - sale

Avoid scams, deal locally Beware wiring (e.g. Western Union), cashier checks, money orders, shipping.

Learn MoreCone Crusher Sizes | Crusher Mills, Cone Crusher, Jaw

Standard cone crushers are built in seven sizes with crushing heads from two to ten feet diameter.

Learn MoreHow Do I Adjust A Cone Crusher? - Blogger

29/05/2022 · Cone crushers can be altered in the space between the mantle and the side. These settings are known as the OSS (open side setting) and CSS (closed side setting.) The size of the largest particle in the finished product is determined by the opening on the side that is open.

Learn MoreCone Crushers - MEKA Crushing & Screening Plants

The cone crusher’s optimised speed and improved crushing chamber design provides high productivity with less we parts, meaning a great savings in labour. The adjustable crushing chamber can provide the required size of material, and is able to meet a variety of customer needs. AUTOMATION SYSTEM

Learn MoreHow to maximize cone crusher performance

In most cases, cone crushers provide reduction ratios (the ratio of the feed size to the crusher vs. the size of the crusher discharge) of

Learn MoreHow to Evaluate/Estimate a Crusher Product Size

2) CSS - as noted above, use a Ball or "Slug" made of tin foil to drop through the lowest nip point with the crusher running. by rope. similar to gaping a cone

Learn MoreSelecting crushing chambers for cone crusher - Outotec

07/04/ · This is discussed in more detail in the 12 tips to maximize cone crusher productivity blog post. Summarizing, larger setting → product size increases, capacity increases, power draw decreases. Example: The HP crusher chamber selection table shows the minimum opening settings. However, the presented settings are provided as a guide only.

Learn MoreA Detailed Overview of Cone Crushers and What You

03/06/ · A first-stage crusher, such as an impact or jaw crusher is used to break raw material down to a size that the cone crusher can accommodate. Cone crushers are typically looked at

Learn MoreCone Crusher Basics - Porter Group

The CH cone crusher can be calibrated to achieve specific results, maximize productivity, and minimize wear, but any calculation will be undermined without a solid understanding of what is going into the crusher. Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feed.

Learn MoreHow to Select and When to Change Cone Crusher Liners

A cone crusher's linings should be replaced when they're at least one inch thick at the bottom and have begun to crack and disintegrate. When the liners are less than a half inch thick, a 10-percent decrease in production is an indication that it's time to change them.

Learn MoreCone Crushers | Moore Watson Ltd

The internal working of the Cone Crusher Specification Dimensions are intended only as a guide for preliminary planning of the installation and should not be used for the construction of foundations etc. Approximate Weights - Unit: KG # 16500 kg = top shell assembly + spider assembly. 9700 kg = top shell assembly only.

Learn MoreHow To Adjust The Cone Crusher - mrsbonn

Cone crushers are only altered in the space between the mantle and side. These settings are called the OSS (open side setting) and CSS (closed side setting.) The gap on the side that is open determines the size of the largest particle of the finished product.

Learn MoreA Detailed Overview of Cone Crushers and What You Need to Know

A first-stage crusher, such as an impact or jaw crusher is used to break raw material down to a size that the cone crusher can accommodate. Cone crushers are typically looked at as a secondary or tertiary stage of crushing. But, they can also act as the first stage provided the material is small enough to fit through the feed opening.

Learn MoreEvaluation of size reduction process for rock aggregates in

1a). The size reduction process in a cone crusher, on the other hand, evolves like a series of crushing events. It simply occurs by the rotation

Learn MoreCone Crusher Performance

For a given crusher, the factors depend on eccentric speed, closed side setting, rock material breakage characteristics and feed size distribution. The main

Learn More

Leave A Reply