JAW CRUSHER SERIES - Mining and Rock

The jaw crusher above is designed for the motor sizes listed in RPG and technical specifications. This means that for harder materials, the crusher will have to be operated at larger settings to avoid overload of drive and/or motor.

Learn MoreJaw crushers, Stationary Jaw crusher series — SRP

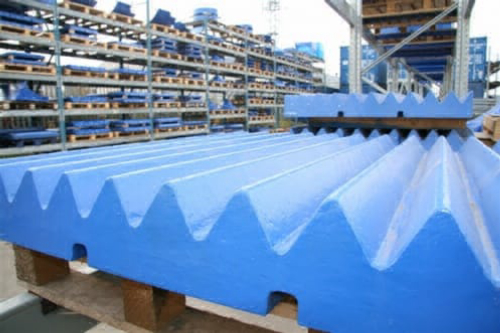

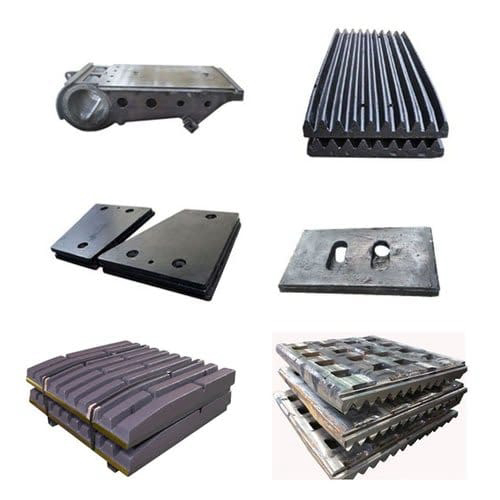

Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop. The wide range of jaw plates can be mixed and reversed to ensure optimal, versatile crushing. EASY TO SET UP AND INSTALL

Learn MoreUsed Jaw Crushers for sale. equipment & more | Machinio

42 x 48 in (1 x 1.2 m) Allis Chalmers jaw crusher. USED. Manufacturer: Allis-Chalmers. - Double toggle jaw - Removed and dismantled - In storage - Bare jaw, no motor - A1 type machine - Feed opening: 42 x 48 inches - Throughput: 290-475 TPH - Closed side setting: 15-25 cm - 150-175 HP motor required. USA.

Learn MoreC Series™ jaw crushers Proven reliability and

C Series jaw crushers have proven to be reliable and productive in thousands of mining, quarrying, recycling and industrial applications with up to 11,000 jaw crusher installations since 1975. Developed to crush the hardest ores and rocks, jaw crushers

Learn MoreJaw Crusher From American Pulverizer

American Pulverizer Jaw Crushers are the affordable alternative in new crushing equipment. Features include: Single wall main frame of stress relieved steel Open back for easy maintenance All working parts lubricated for moisture and dirt protection Reversible manganese jaw dies for maximum wear life Large, spherical, self-aligning roller bearings

Learn MoreJaw Crushers | McLanahan

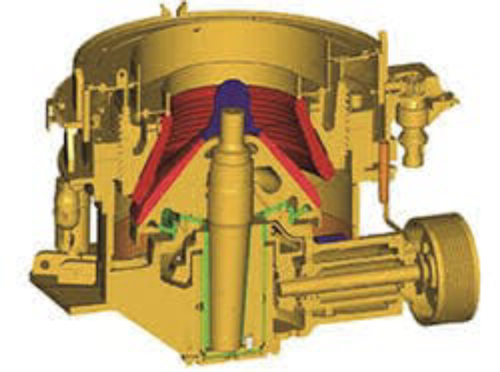

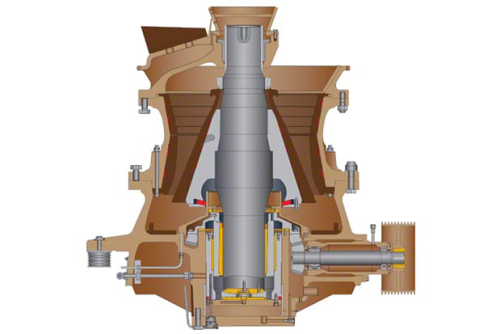

A Jaw Crusher uses compressive force for breaking material. This mechanical pressure is achieved by the crusher's two jaws dies, one of which is stationary and the other is movable.

Learn MoreJaw Crusher,stone crusher machine factory - walker mining

Jaw crusher is widely used in mining, metallurgical industry, building material, highway, railway, water conservancy and chemical industries. Various materials with compressive resistance less than 350 Mpa can be crushed. In the process of crushing huge rocks into small rocks, the first crusher is usually the “main” crusher.

Learn MoreJAW CRUSHER - Gongyi Jingying Machinery Manufacturing

Jaw crusher is used for Aggregates Shaping, Mechanism sand, Bituminous Concrete, Metal Mine, Chemical, Road, Railway,Metallurgy, Construction, Highway, Water Conservancy Capacity 5-500t/h Max feeding size 200mm-1200mm Raw materials River stone, gravel, granite, basalt, minerals, quartz, diabase, etc. Application

Learn MoreNew & Used Jaw Crushers for sale - GrinderCrusherScreen

New & Used Jaw Crushers for rock, brick, concrete, and more in top brands such as Evortle, Extec, , Red Rhino, KPI, Komplet, and More. From Small/Mini Jaw Crushers to Large Jaw Crushers. Select Language. English Deutsch Français Español Italiano Nederlands. East Coast: 770-433-2670. West Coast: 971-344-0001.

Learn MoreFreedom Series Jaw Crushers | McLanahan

Freedom Series Jaw Crushers Often used as the first stage in a crushing circuit, Freedom Series Jaw Crushers can crush even the hardest of materials. The attack angle and crushing stroke pattern are engineered to increase capacity up to 15% while minimizing we the jaw dies. Applications Aggregates Concrete Crushing Frac Sand Mining Jump To:

Learn MoreUsed Jaw Crushers for Sale | Surplus Record

Jaw Crushers Manufacturers (4) Allis-Chalmers (3) Lippmann (2) Bico (1) Denver (1) (1) Kue Ken (1) Merz (1) Minyu (1) (1) Pioneer (1) Sturtevant (1) Universal (1) Add manufacturer Models C140 (3) 106 (1) 120S (1) 150 (1) 160 (1) 170 (1) 4248 (1) 90 (1) BB250/400 (1) C100 (1) C160 (1) LJ2745 (1) S-T (1) ST1109 (1) Add model

Learn MoreJaw crusher types and applications - News of Joyal Crusher

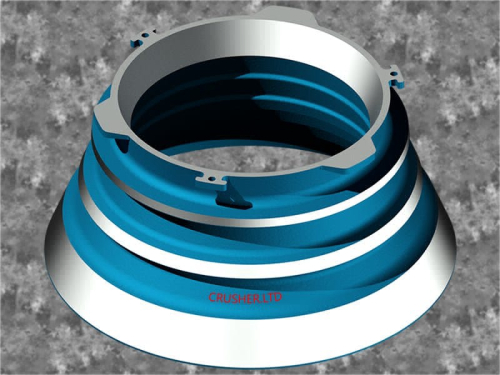

In terms of medium and fine crushing, jaw crushers are mostly selected for small output. Otherwise, choose a cone crusher. Feeding mouth width greater than 600mm is a large-scale crusher, feeding mouth width 500-600mm is a medium-sized crusher, and feeding mouth width is less than 500mm is a small crusher. The jaw crusher has a crushing ratio

Learn MoreLaboratory Jaw Crusher - 911Metallurgist

Jaw Crusher Features and Benefits Better crushing performance due to 3000 Watt (strong 3 phase motor) Optimum crushing results Easy and quick access to the crushing chamber (no tool required) Stepless adjustment of gap setting (no tool required) CE certified Removable infeed hopper with safety baffles or batch loader

Learn MoreJaw Crushers - Powerscreen

Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size. Powerscreen jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear parts. Powerscreen Merchandise

Learn MoreJaw Crusher | manufactor | thyssenkrupp Mining Technologies

Jaw crushers are used within the aggregates, cement, and mining industry, as they have been proven to be an efficient primary crusher for hard rock materials such as granite and others.

Learn MoreWhat Is a Jaw Crusher? Here's How It Works - Cutting Technologies

Jaw crushers typically use the principles of compression and friction to break materials down. They're extremely powerful equipment that should be used with the utmost care. Jaw crushers are so powerful that they've earned the moniker "rock breakers" because of their brute force. All jaw crushers will have one fixed jaw and a moving one.

Learn MoreJaw Crushers - high quality and reliability from RETSCH

Jaw Crushers The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials. The variety of materials offered,

Learn MorePioneer® Jaw Crushers - Astec

Pioneer® Jaw Crusher Overview Applications Construction Aggregates Construction aggregate is typically medium or coarse material that is used in construction applications. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles. Learn More

Learn MoreJaw Crusher For Sale - Can Process All Kinds Of Rocks

In this 200tph mobile crusher plant, we provide an APJ-7510E jaw crusher. The maximum feeding size of APJ-7510E jaw crusher is 630mm, and its processing capacity can reach 110-320 t/h. Other equipments include an APG-4211W vibrating feeder, APC-200C medium crushing compound cone crusher and APS-2160Y4 vibrating screen.

Learn MoreAutomatic Jaw Crusher Granite Jaw Crusher Brick Mobile Crushing Station

Automatic Jaw Crusher Granite Jaw Crusher Brick Mobile Crushing Station Stone Crusher. Jaw crusher is commonly known as jaw crusher, also known as tiger mouth. The crushing chamber is composed of two jaw plates, the movable jaw and the static jaw, and the crusher completes the material crushing operation by simulating the movement of the two

Learn MoreJaw Crushers | Crushing Equipment | Minyu Machinery Corp

2022/2/24 · Minyu Jaw Crushers are Ideal for Crushing in Large Quantities. With larger feed openings and bigger crushing strokes, the Minyu Jaw Crushers are suitable for crushing big

Learn MoreJaw Crushers | Heavy Duty | Finlay

Jaw Crushers Finlay® tracked Mobile Jaw Crushers are renown for their capabilities in the reduction and sizing of aggregates for construction materials and also recycling construction waste.

Learn MoreSMAN jaw crusher - Shakti Mining

SMAN jaw crusher A jaw crushers is a crushing machine designed considering a primary stage crushability for materials such as rock, mineral, ROM and building rubble. jaw crushers design focuses on compression type crushing with feed of material being received from the top of the crushing chamber that consists one side fix and other movable type cast manganese jaw liners, the moving jaw is

Learn MoreJaw Crusher - Stone Crushers & Grinding Mills for Mines and Quarry

As the first process of stone crushing line, Jaw Crusher always plays important role. This machine is possess of optimized crushing chamber, heavy eccentric shaft and high manganese steel jaw plate, which takes advantages of high efficiency, strong crushing ability and low investment costs. Applications: Mining, metallurgy, construction

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design

Learn MoreJaw Crusher Working Principle – StudiousGuy

A jaw crusher mainly works on the principle of reciprocating motion exhibited by the moveable jaw of the jaw crusher. The repeated movement of the jaws results in the development of compression force that further causes the breakdown of the rock or the ore placed between the two jaws into smaller pieces. The movement of the jaw crusher is

Learn MoreJaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

DOVE Jaw Crushers are ideal rock crusher machines, highly efficient and economical for handling Primary and Secondary stone crushing applications of various ores and bulk materials with compressive strength below 320 MPa.DOVE Crushers are supplied in Stationary complex plant configuration, or in Portable and Mobile configuration.. Designed with optimum cavities and height in relation to feed

Learn MoreJaw Crushers - Astec - Default

Jaw Crushers Jaw Crushers Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing

Learn MoreLaboratory Jaw Crushers - Gilson Co.

LC-28 3x4in Laboratory Jaw Crusher reduces 3in feed aggregate and rock material to a product with 50% passing 0.25in (6.3mm) sieve. Jaw opening quickly adjusts from 0.375 to 1.5in (9.5 to 38mm). The operation of the overhead eccentric is regulated by the variable speed controller up to 375rpm and quickly crushes material for final testing or to

Learn MoreJaw Crushers for sale

OLESI 8 Orbital Jaw crusher rock grinding mill gold mining equipment silver ore. $8,400.00. or Best Offer. 46 watching. SPONSORED. I-Rock 2440 Track Jaw Crusher. Cat Diesel Power 500 Hours,

Learn MoreJaw Crusher Manufacturer | Propel Industries

Jaw Crusher Manufacturer | Propel Industries WATCH VIDEO TECHNICAL DATA * Details may vary based on application ** Weight inclusive of motor & accessories. Note: All the above technical details may vary at any time during engineering process & design development. PLANT INSTALLATION RELATED PRODUCTS CONE CRUSHERS GYRATORY CONE CRUSHER

Learn More

Leave A Reply