Best 21 Construction Companies in Hillsboro, OR

SuperPages SM - helps you find the right local businesses to meet your specific needs. Search results are sorted by a combination of factors to give you a set of choices in response to your search criteria. These factors are similar to those you might use to determine which business to select from a local SuperPages directory, including proximity to where you are searching, expertise in the

Learn MoreCrusher Jaw Plates For Popular Brands By Hunan JY Casting

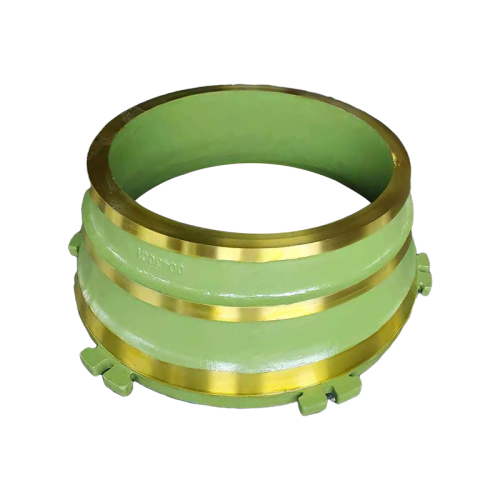

Work hardened upper jaw dies are installed at the bottom of the crushing chamber. Which is the best material for crusher jaw plates? Standard Manganese Steel The standard material for jaw plates is manganese steel, which is also called austenitic manganese steel or modified austenitic manganese steel. There are three common grades: Mn14Cr2 Mn18Cr2

Learn Morerushing plate profile of jaw crushers with simple jaw movement for

Jaw Crusher ScienceDirect. 0101 The jaw crusher is primarily a compression crusher, while the others operate primarily by the application of impact 42 Design of Jaw Crushers Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw) The faces of the plates are made of hardened steel Both

Learn MoreJaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale - Willing

We can produce a variety of meet the requirements of the jaw plate according to the customer’s model . Because of the use of manganese content of 13% to 30% of the high manganese steel and ultra-high manganese steel, and the unique heat treatment, our products possess strong wear resistance and long service life.

Learn MoreMaterial Selection of Jaw Plate of Jaw Crusher

Therefore, it is necessary to fully understand the working conditions and select materials reasonably. 1. Improve the hardness of the jaw plate. The larger the size of the jaw crusher, the larger the size of the crushed material, and the greater the impact load the jaws bear. When selecting the material, the first consideration should be to

Learn MoreMaterial of Mobile Jaw Crusher and Fixed Jaw Plate

As a part with a high jaw wear rate, the choice of jaw plate material is related to the user’s cost and benefit. 1. High manganese steel. High manganese steel is the traditional material of the jaw plate of the jaw crusher, which has good impact load resistance. However, due to the structure of the crusher, the opening angle between the

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production. It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance.

Learn MoreThe 5 Abrasion Reasons Of Jaw Plates In Jaw Crusher (I

In jaw crusher, the crushing cavity is formed by movable jaw plate and fixed jaw plate. As we know, raw materials are crushed in the crushing cavity, so jaw plates directly contact with the raw material and are easily damaged. In this case, jaw plates are the main wear-resistant parts in jaw crusher and need to be changed regularly.

Learn Morehigh manganese steel, casting, wearing resistant foundry | Sinco

Sinco Mining Machinery Manufacturing Co., Ltd. is the leading wearing parts manufacturer in China. Our casting foundry located in Xinyu City, Jiangxi Province, 3hous by high speed train from Shanghai or Canton. With workshop 43,000 square meter and 200 skilled workers, we have 2 production lines-Resin sand casting production liner and lost

Learn MoreWhat is the best material for crusher jaw plates?

Dec 23, · Mn18Cr2 is the most popular material for casting jaw crusher jaw plates. This Mn18Cr2 jaw plates widely in crushing difficult and non-abrasive blasted rock, medium and non

Learn MoreJaw Plates - SHANVIM

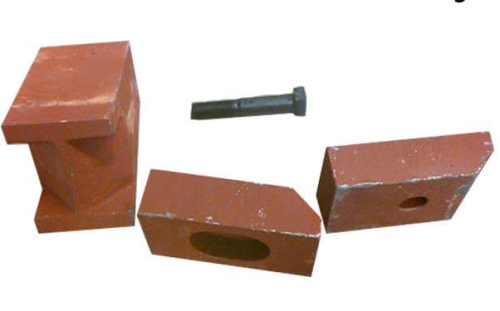

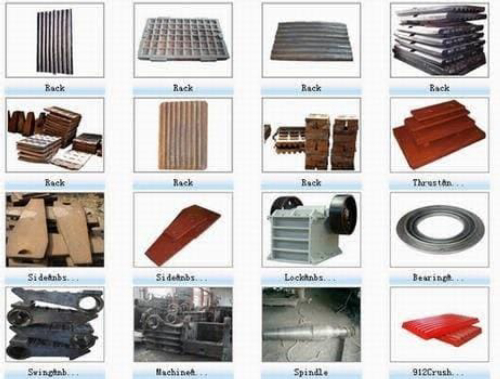

The highest crushing material is 320MPa. Jaw crusher parts can also be referred to as jaw crusher wear parts, is an important part of the jaw crusher; We can provide various types of jaw crusher wear parts, such as fixed jaw plate, movable jaw plate, toggle plate, liner plate, but also according to the drawings provided by customers to create

Learn MoreCrusher Jaw Plate for Sale - EB Castworld % Crusher Jaw Plate

Type: Jaw Plate / Crusher Plate; Machine Type: crusher / Jaw crusher; Applicable Industries: Energy & Mining; Manganese Contents: Mn13Cr2, Mn18Cr2, Mn22Cr2, etc; Features & Advantages: Materials: High manganese or other materials as your requested. Use: Wear parts for crushers in the quarry, mining, construction and metallurgical industry

Learn MoreResminer Stone Crusher Jaw Plates - Wear Resistance Supplier in China

Resminer Stone Crusher Jaw Plate Features Resminer stone crusher jaw plate is made of the special quality of manganese material. Our products are ISO certified. Competitive price in the market. Stone crusher jaw plate has long life span of service. High rate of corrosion resistance. Resminer Stone Crusher Jaw Plate Application Area

Learn MoreJaw Crusher for Hard Materials | DASWELL

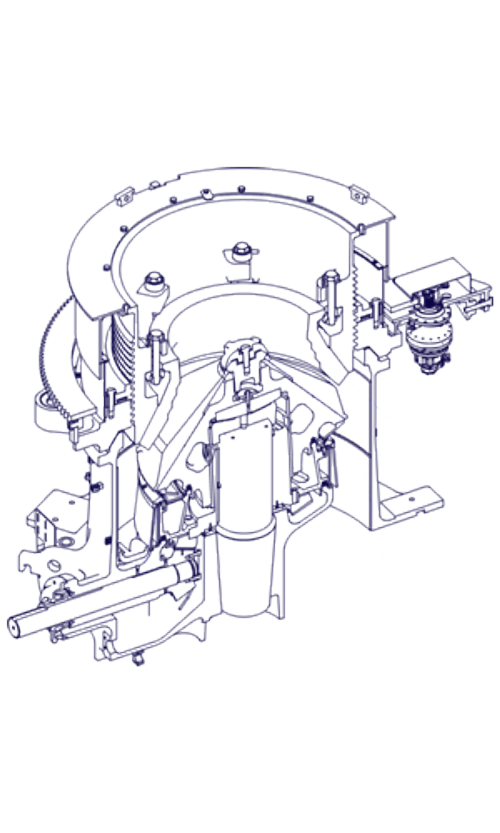

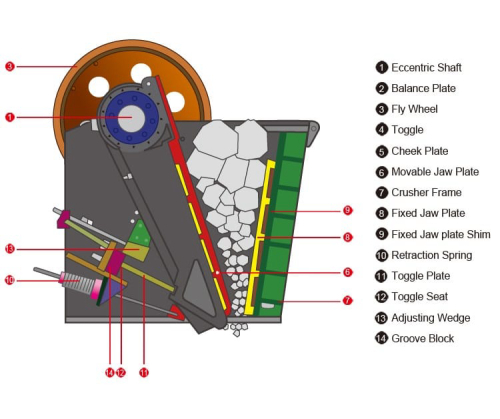

The jaw crusher is mainly composed of frame, eccentric shaft and bearing, main shaft, flywheel, toggle plate, fixed and movable jaw plate and other components. The working mode of the jaw crusher is the driving extrusion type, and the material is crushed in the crushing cavity composed of the movable jaw and the fixed jaw.

Learn MoreClavicle Plating System | Acumed

The Acumed Clavicle Hook Plating System includes four plate lengths and three hook depths. The system provides a third solution for acromioclavicular (AC/CC) joint dislocations and lateral clavicle fractures, in addition to both the Acumed Distal Clavicle Plates and Acu-Sinch Repair System. The Acumed Clavicle Hook Plating System is intended

Learn MoreWhat happened? Jaw plates which need to change frequently for jaw crusher!

Nov 26, · If you need a replacement jaw for your crushing machine that can withstand the toughest conditions, then you need BDI’s manganese jaws. Our replacement jaw feature in three grades depending on the crushing conditions encountered 13%MN, 18%MN, 21%MN. BDI’s replacement jaws offer to wear life and fit and go through a rigorous quality control process.

Learn MoreWhat are the Materials of the Jaw Crusher Plates and Which is Better

High manganese steel is the traditional material of the jaw plate of jaw crusher, which has good impact load resistance. However, due to the structure of the crusher, the opening angle between the movable and fixed jaws is too large, which is easy to cause abrasive sliding and deformation due to deformation.

Learn MoreJaw Crusher Plate Suppliers - EB Castworld

Jaw Crusher Plate Suppliers. product: Jaw Crusher Plate Type: Jaw Plate MOQ: 2 pieces Jaw plate size: Customize Processing Type: CASTING Material: High Manganese Steel Machine Type: crusher/ Jaw crusher Condition: New Warranty: 6 months Applicable Industries: Energy & Mining Usage: Ore mining Manganese Contents: Mn13Cr2, Mn18Cr2, Mn22Cr2, etc

Learn MoreHow to Choose the Right Jaw Plates for Jaw Crushers - Ware

Nov 05, · Jaw plates are usually made of high manganese steel or medium-carbon-low-alloy cast steel, with different materials providing different advantages, depending on material and crusher types. ·High Manganese Steel High manganese steel jaw plates are wear-resistant and last longer but cost more to make.

Learn MoreHow to Choose the Right Jaw Plates for Jaw Crushers - Ware Resistance

A jaw crusher crushes stone or ore using large steel crushing plates (jaw plates) that move in two converging tracks with an adjustable gap width. Raw material enters at the top of these tracks, and as it slides down, it is squeezed by these plates until finally getting jammed as its size prevents further convergence.

Learn MoreJaw Crusher Toggle Plates vs. Hydraulic Toggle Relief Systems

Traditionally, jaw crusher toggle plates are made of metal machined or cast in a way that they are expected to fracture or bend at a certain pressure, indicating something too hard is in the crushing chamber.

Learn MoreCRUSHER JAW PLATE-Bogvik Wear Material

CRUSHER JAW PLATE. Shanghai Bogvik Wear Material Co., Ltd. Tel: +86 158-5198-9372. Email: [email protected]. Fax: +86 158-6899-9133. CONTACT US. SWING JAW PLATE. Shanghai

Learn MoreJaw Plates: How to Choose the Right One for Different Types of Jaw Crushers

The jaw plate is an important part in the jaw crusher equipment, and its service life directly affects the whole jaw crusher equipment. Therefore, you must consider the hardness and toughness of the jaw plate when you want to choose a correct one. These jaw crusher plates are deliveried to Indonesia. If the hardness of the jaw plate is high

Learn MoreCrushed Fines | Acme Sand & Gravel

Crushed Fines and also known as Quarry Dust, is a form of fractured gravel chips and fine dust used to solidify the base under patios and walkways. The Sub-Base is laid above the ABC or Sub-Grade at 1″ to 2″ inches on light weight traffic areas like pathways and paver patios. Cross-Section layers that make up a mortar-less or "dry-laid

Learn MoreJaw Plate Materials | Crusher Mills, Cone Crusher, Jaw Crushers

jaw crusher plate suppliers and jaw crusher plate Details: 1.jaw plate material :Mn14Cr2 and Mn18Cr2 2.high manganese jaw plate 3.jaw plate is use to jaw crusher plate.Place of Origin:

Learn MoreEngineered for the toughest feed materials ® C

C Series™ jaw crushers are engineered for the toughest feed materials in the primary crushing stage. They deliver the crushing performance you need, and have proven their reliability and productivity in well over 10,000 quarrying, mining, recycling and industrial minerals applications since 1975.

Learn MoreJAW PLATES - Precision Casting

A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing crushing in a jaw crusher is achieved when the movable

Learn MoreJaw Plate - Casteel Foundry

Jaw Crusher Wear Parts: Item Names: Jaw Plate s ,Stationary Jaw Tooth, Movable Jaw Die Fixed Jaw, Swing Jaw Plate ,Jaw Fixed, Jaw Moveable , Cheek Plate , Side Plate Casting Material: Austenstic Manganese Steel (Mn14, M14Cr2, Mn18Cr2, Mn22Cr2)

Learn MoreJaw Plate - Toughing Crusher

5 rows · Additional information. Introduction:Jaw plate is the main wear part of jaw crusher, which is

Learn MoreJaw Liners, Jaw Plate Material And Manufacturer | Quarrying & Aggregates

Jaw crusher liner material In general, the jaw plate is made of high manganese steel. The manganese steel content of Rayco's products ranges in 12-14%, 18% and 20%. Jaw crusher liner manufacturer In the mining crushing and screening industry, manufacturers usually provide very few jaws die design options.

Learn MoreHillsboro, OR - Crushers For Sale - Equipment Trader

Crushers Crushers are an important part of many industrial and materials processing projects. They allow for the crushing of rocks into gravel, smaller rocks, or even miniscule dust. Equipment Trader's website allows users to quickly search for the best models near to their zip code from the brands and dealers that they have come to trust.

Learn More

Leave A Reply