Jaw Crusher Liner, Swing and Stationary Jaw Plate

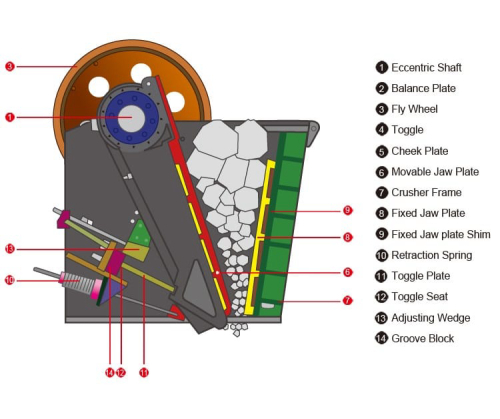

The jaw crusher liner is also called the tooth plate, which is an important part of the jaw crusher. A set of jaws is usually composed of movable jaws and fixed jaws. According to different models of jaw crushers, the jaws also have the same size and model. As the preferred equipment for coarse crushing, the aggregate industry has high

Learn MoreCrusher Liner Plates for High Chromium - EB Castworld

Crusher Liner Plates for High Chromium. Material: High Chrome Cast Iron & Ni Hard White Iron. Dimensions: as per drawings. Special Features: We adopt Sand Cast Process to make High Cr & Ni hard mill machine cooling plate. We do quenching & tempering treatment for high Cr & Ni hard white iron plates to achieve high hardness.

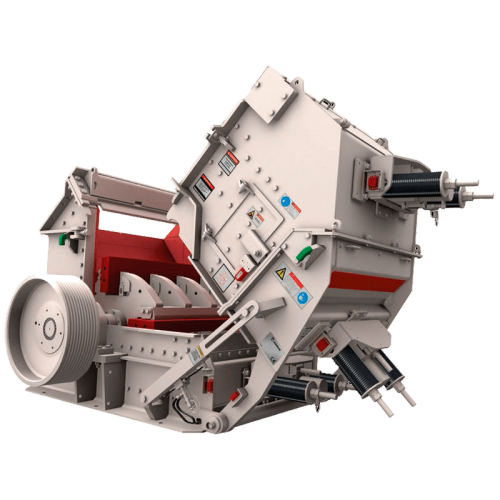

Learn MoreLiner wear in jaw crushers - ScienceDirect

01/01/2003 · The rotating eccentric shaft and the link give the right liner an oscillating motion that will crush the material. The left, stationary liner has three load cells. Two of them are horizontal, to measure normal forces, and one vertical to measure the frictional force. The force cells have been designed to be insensitive to bending and torsion.

Learn MoreCrusher Plate Liner Price - Buy Cheap Crusher Plate Liner At Low Price

Comparing crusher plate liner prices. You can easily wholesale quality crusher plate liner at wholesale prices on Made-in-China.com.

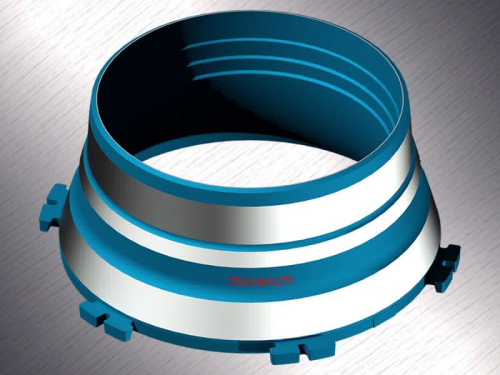

Learn MoreUS3645460A - Upper liner for crushers - Google Patents

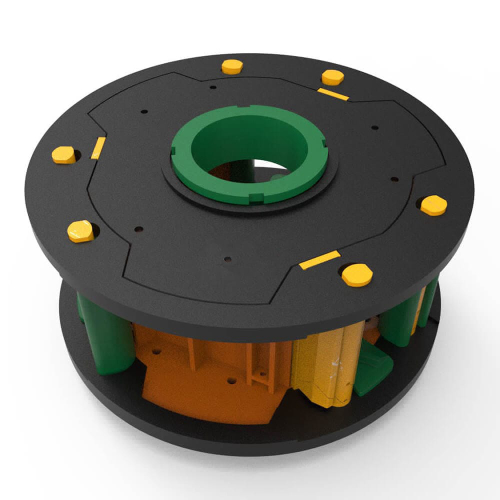

A bowl liner and a bowl for use in gyratory cone crushers in which the body of the liner has improved wear-resistant features and the liner is mounted in a shock-free manner to greatly increase the life of the liner. A circumferential, inwardly extending bowl ledge is provided with sockets through which inserts which are fused to the liner body project.

Learn MoreTips For Buying Crusher Wear Liners - Qiming Casting

26/07/ · New wear liners supplied for your crusher are usually supplied neatly painted and packed for good presentation. An initial visual inspection is usually all that is possible and provided there are no surface imperfections present the liner is stored for later use. There may be an incentive to dispose of worn crusher liners and clean up the yard.

Learn MoreTHOR liners for crushers by Element Global

Our THOR linings are suitable for all companies that are engaged in crushing. The manufacturer's product range includes wear parts for jaw, cone, and gyratory crushers. All alloys that are used

Learn MoreResearch on the Wear Behavior of the Fixed Cone Liner of a

The static friction coefficient between the manganese ore and the cone crusher is studied and calibrated using the slope method. The relative

Learn MoreCone Crusher Liners Selection - Wear Parts For Industry - Qiming Casting

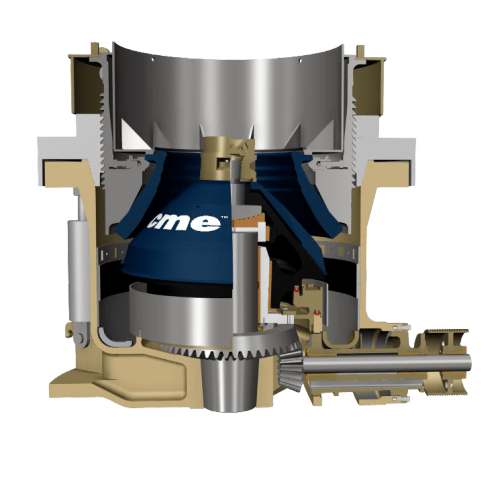

2.Crusher Liner's Material. Cone crusher wear parts, concave and mantle, are casting by manganese steel. Mangalloy, also called manganese steel or Hadfield steel, is a steel alloy containing an average of around 13% manganese. Mangalloy is known for its high impact strength and resistance to abrasion once in its work-hardened state.

Learn MoreCrusher Socket Liner

Crusher Socket Liner. We help the world growing since 1983. Career. Give Feedback. Contac Us. English. Email Support 0086 21 58112866. Call Support [email protected]. Home.

Learn MoreCrusher Wear Parts - Foreman Equipment Ltd

Wear occurs in all crushers, but you can help control costs by choosing the right liner configuration for the desired application. Crusher wear parts from

Learn MoreCrusher Wear Parts & Liners | Wear & Impact Resistant Steel

Find crusher wear parts and liners for all types of impact crushers. Clifton Steel can make the right wear liner for the job.

Learn MoreBowl Liner & Mantle | Wear Resistant Crusher Parts - GTEK

Cone Crusher Mantle & Bowl Liner are used for compressing rocks and ores into small size. GTEK provides OEM interchangeable mantles & bowl liners with long

Learn MoreTips For Buying Crusher Wear Liners - The Riverenza

Crusher liners wear differently depending on their feed material gradation and discharge setting. Your replacement wear part provider should conduct a wear study to determine the exact conditions that affect your liners' life expectancy. If you can extend the liners' service life with thicker liners, they're an excellent choice.

Learn MoreJaw Crusher Liner Plate Design & Profile Shapes

Jaw Crusher Liner Plate Design & Profile Shapes. Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates. This type of plate has been the standard from the time of its inception, emulating, in this respect, the straight concaves in the gyratory machine.

Learn More54 Tons Microalloy Crusher Liners For Mongolia Customer - Hunan JY Casting

We meet SOYO at the Bauma Fair. By analyzing the usage and wear of crusher liners, our engineers put forward micro-alloy + high-manganese steel crusher liners to improve product life and reduce downtime for crushed iron ore. Subsequently, SOYO tested a set of microalloy crusher liners in crushing iron ore.

Learn MoreCrusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY Casting

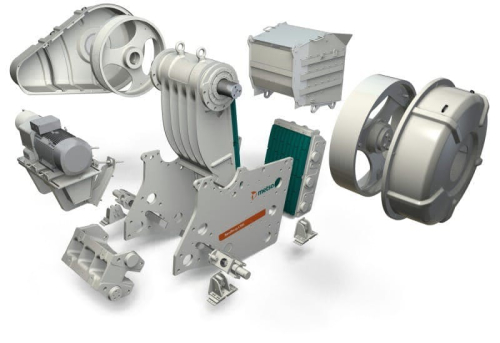

What We Offer. Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands.

Learn MoreManganese Crusher Liners - Mining Wear Parts

Will manganese crusher liners optimise my crusher performance? Our aftermarket Manganese crusher liners for cone, jaw, gyratory, and impact crushers are cast

Learn MoreStep by Step Guide to Replace Ball Mill Liners - Qiming Machinery

Ball Mill liners are an extremely efficient variant of mill liners, which is what compels the ball mill liners manufacturers to manufacture them in the first place. If used properly, they may last pretty long. However, at one point or another, we may be obligated to replace the ball liners mill, due for various reasons.

Learn MoreCME™ Crusher Liners - H-E Parts

CME™ Crusher Liners H-E Parts liner development program and CME™ Crusher liners provide customers with application-specific performance at the lowest total operating cost by matching the optimum profile with the most appropriate grade of manganese steel chosen from one of the following ranges:

Learn MoreGyratory Crusher Liners

Crusher operating parameters, liner selection, material selection, plant process review, and customer goals all go into providing our customers with the ideal solutions. If more than one option is available, we offer cost-benefit options to make the

Learn MoreCrusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY

19/04/2022 · What We Offer Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands. Custom or OEM Wear Parts

Learn MoreLiner wear in jaw crushers | Request PDF - ResearchGate

Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major

Learn MoreCrusher Concave Liners and Mantle Wear - Mineral Processing

24/07/ · Crusher Concave Liners and Mantle Wear Previous Next As the Crusher Concave Liners and Mantle Wear out there is a period when the crusher won’t be as efficient as it could be. This can be a very frustrating period for the operators. Since the throughput drops and operators have to work harder, usually doing the same thing over and over again.

Learn MoreAR Steel Crusher Liners - Crusher Wear Liner Supplies - Ford Steel

Ford Steel offers Wearalloy 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy plate up to 4-inches thick for AR steel crusher liners in impact, jaw, cone and other types of crushers. Wearalloy Superclad available for use as cheek plates too. Our company provides crusher wear liner supplies to a wide range of industries including: Sand & Gravel

Learn MoreSelecting Jaw Crusher Liners | Shape & Design

A client needed finer crush out of his Jaw Crushers. I proposed this literature from Metso.com to help him select a jaw liner set.

Learn MoreAR Steel Crusher Liners - Ford Steel

Our company provides crusher wear liner supplies to a wide range of industries including: Sand & Gravel; Cement; Construction. Contact Our Team.

Learn MoreCrusher Liner Price

Crusher Liner Price - Select 2022 high quality Crusher Liner Price products in best price from certified Chinese Crusher Blow Liner

Learn MoreCS Series Cone Crusher Liners - Hunan JY Casting

Experience customer support beyond what you'd get from ® crusher dealers. Hunan JY Casting offers high-quality CS series cone crusher liners for your ® crusher-guaranteed to perform as well as (or better than) OEM crusher parts. Hydroset™-style crushers have been around for decades. As the brand names have changed

Learn MoreThe Best Liner For Cone Crusher Manufacturer in China, Supply Liner For

Best Liner For Cone Crusher from China, Supply Various of Liner For Cone Crusher with High Quality. Company Details. ZHEJIANG FULE MINING MACHINERY CO., LTD [Zhejiang,China] Business Type: Manufacturer , Trade Company; Main Markets: Americas , Asia , East Europe , Europe , North Europe , Other Markets , West Europe , Worldwide;

Learn MoreCrusher Liner Solutions - Bradken

Bradken Is A Leader In The Design, Manufacture And Supply Of Crusher Liners For Primary And Secondary Applications In The Global Mineral Processing And

Learn More

Leave A Reply