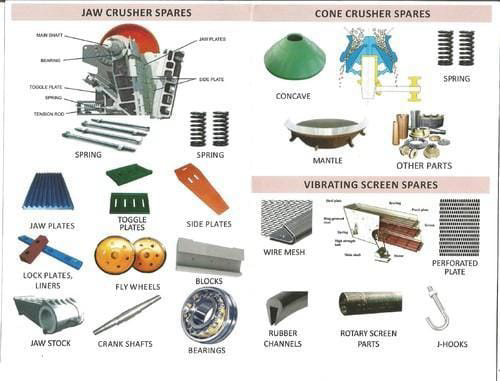

Jaw Plates- The Right Jaw Plates for the Jaw Crushers and Its Purpose

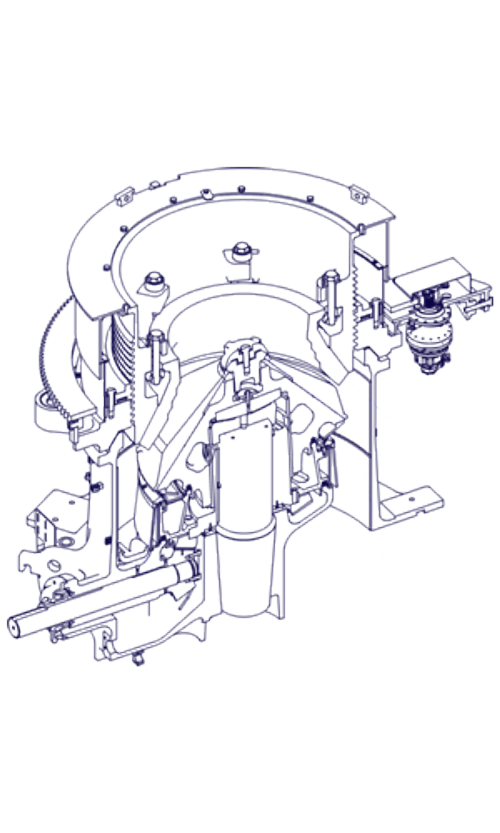

The jaw crusher is a single toggle type of crushing equipment mainly used for variety of applications, including the medium to fine crushing process in the fields of mining, chemical industry, building materials, and refractories. As its name implies, this machine functions by using the "jaw plate," which is derived from its wear-resistant

Learn MoreJaw Crusher Toggle Plates vs. Hydraulic Toggle Relief Systems

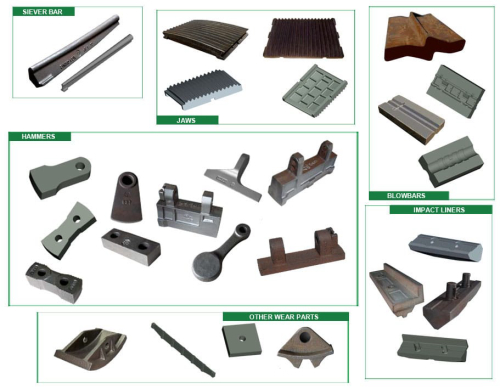

What is a toggle plate? In a machine like the jaw crusher, toggle plates are a valuable component that essentially serve as a safety joint

Learn MoreQJ341 Mobile Jaw Crusher

Easy access to the engine compartment and in-built automatic central lubrication system reduces maintenance time, and with wear resistant liner plates fitted as

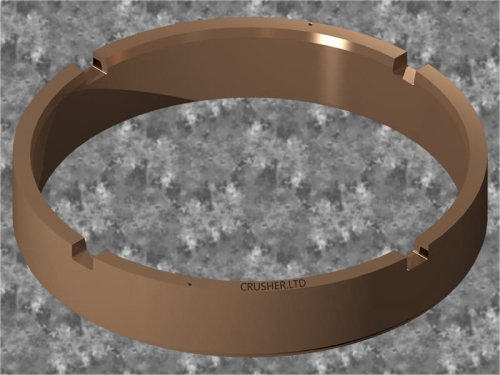

Learn MoreMANTLE A M1 H28800 | mention the purpose of jaw plates

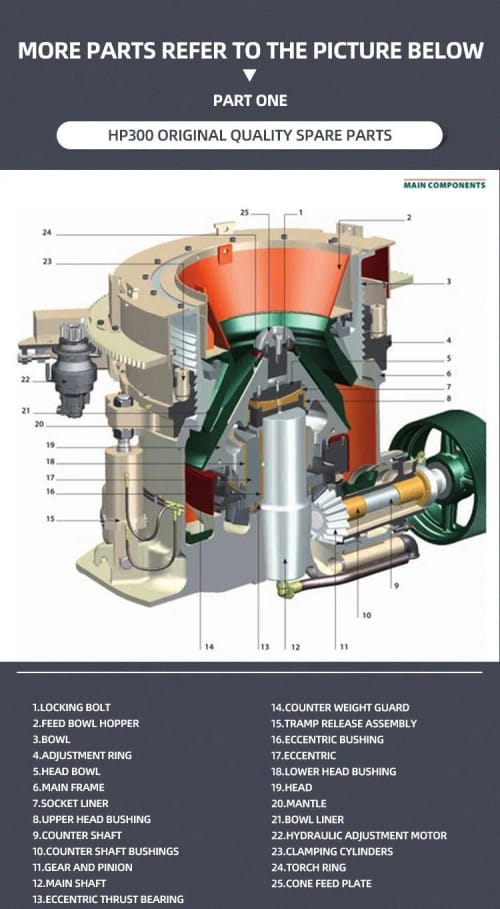

3054 Jaw Crusher; 2036 Feeder Screen Jaw Plant; CJ612 4448 Jaw Crusher; Screen Jaw Combo; Cone Crushers. CH660 Hydrocone; CH550 Hydrocone; CH540 Hydrocone; CH440 Hydrocone; CH430 Hydrocone; CS660 Gyrocone; CS550 Gyrocone; CS440 Gyrocone; Closed Circuit Crushing Plant; CH430 Self-contained cone;

Learn MoreThe Right Jaw Plates for the Jaw Crushers and Its Purpose

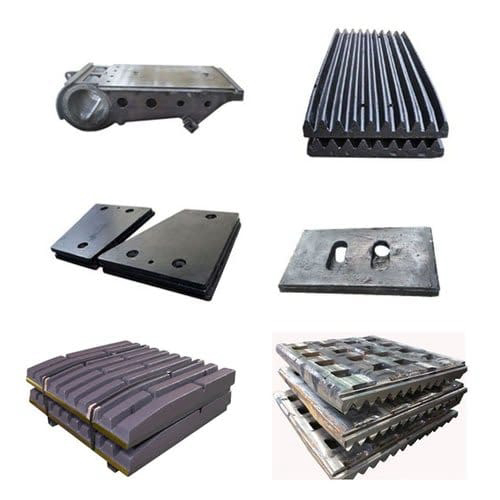

The Jaw plates are designed pieces of steel that can be found inside the Jaw crushers. It can help crush heavy materials easily.

Learn MoreWhat Are the Functions of Toggle Plate of Jaw

8/9 · What Are the Functions of Toggle Plate of Jaw Crusher? -08-09 09:08:35. Toggle plate is the most simple and low-cost part of Jaw Crusher, which is usually made by cast iron. It is the driving part of jaw crusher and has three main functions. That is, transmit power, adjust discharge opening and function as a safety device.

Learn MoreJaw Crushers JW Series - Corporation

use. The rugged design delivers the reliability you can expect from Cedarapids. Replaceable backing plates protect the jaw die seating.

Learn MoreA REVIEW - African Journals Online

improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing and easily adjustable toggle plate.

Learn MoreKnow-how - RUBBLE MASTER

There are cheek plates mounted on the insides of the crusher to act as additional wear parts to protect the crusher mainframe. The two jaw plates are positioned

Learn MoreJaw Crusher Working Principle - 911 Metallurgist

The combination of favorable crushing angle, and non-choking jaw plates, used in this machine, promotes a much freer action through the

Learn MoreJaw reconstruction with fixation plates] - PubMed

The use of internal fixation plates in the reconstruction of mandibular continuity following serious injury, or resection of mouth floor tumours, is described. When complicated fractures are involved, the combined employment of osteosynthesis with steel wires and fixation plates is advised. Three il

Learn MoreJaw Plate - Toughing Crusher

Introduction:Jaw plate is the main wear part of jaw crusher, which is divided into moving jaw plate and fixed jaw plate TOUGHING’s jaw plate and cheek plate is manufactured with high manganese steel of Manganese 13%-30% to meet all kinds of requirement from clients. Through the special heat-treatment process, our jaw plate has stronger wear

Learn MoreDE-1: Lesson 2. THE BENCH WORK TOOLS AND ITS USES

A separate cast steel plates known as jaw plates with teeth are fixed to the jaws by means of set screws and they can be replaced when worn.

Learn MoreIn- depth – Components of a Jaw Crusher - Propel Industries

The inward facing side of the jaw crusher pitman is covered with a jaw plate made of manganese which is an extremely hard metal.

Learn MoreNW115 FASTENING PART Medieval Mereology

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session: HTTP: CookieConsent: Cookiebot: Stores the user's cookie consent state for the current domain: 1 year: HTTP: olfsk: Olark: This cookie is necessary for the login function on the

Learn MoreJaw Crusher Toggle Plate Manufacturer from Indore

Manufacturer of Jaw Plates - Jaw Crusher Toggle Plate, Manganese Jaw Plates, premium quality and several attractive features which are mentioned below:.

Learn Moreswing jaw crusher mention the purpose of jaw plates

Heavy Duty Jaw Crushers. Puzzolana Jaw crushers -Stone Crushers are Manufactured in India This produces a "Flat Elliptical Movement" at the bottom of the swing jaw which

Learn MoreMeans for securing jaw plates in a jaw crusher - Google Patents

A jaw plate part for securing jaw plates to a jaw crusher of the jaw crusher can be arranged to work as a wedge being detachable from the jaw crusher.

Learn MoreC110 PROTECTION PLATE C110 PITMAN | mention the purpose of jaw plates

C160 Jaw Plate One Piece design or 2 Piece Design. Jul 26, · 1 mm0266492 pitman assembly 1 21177.75 3 . 2 mm0263144 frame assembly 1 33889.18 4 14 447156 protection plate 1 230 . 15 447157 protection plate 1 225 c110: c120 c125: c130: c140 Plate Compactor C110 - W&H Machinery(VATOLE®) Plate Compactor C110.

Learn MoreJaw Plates - SHANVIM

JAW CRUSHER PLATE-JAW LINER. Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn Moremodel 2436 jaw crusher pioneer parts mercedes c-class specifications

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session: HTTP: CookieConsent: Cookiebot: Stores the user's cookie consent state for the current domain: 1 year: HTTP: olfsk: Olark: This cookie is necessary for the login function on the

Learn MoreJaw Crusher Cheek Plates | Designed for a Purpose - Mineral

3/19 · Jaw Crusher Cheek Plates | Designed for a Purpose. The first part of a jaw crusher’s cheek plate select or design is asking the question: What do I want my crushed rock product to look like? A chrusher’s cheek plate will help you ‘hold the rock in place’ will you crush it if you will. Here are some standard styles of jaw crusher cheek

Learn MoreWhat are the 2 abrasion reasons of jaw plates in a jaw crusher?

Jaw Crusher is a crusher composed of two jaw plates, a movable jaw and a static jaw, which simulates the movement of the animal's jaws to complete the material

Learn MoreJaw Plates | Shanghai GDOO Mining Technology Ltd

Why Choose GDOO® Jaw Plates. ① We offer a variety tooth profiles and surface shapes; ② We offer different materials of jaw dies; ③ We produce more wear-resistant products; ④ We extend the service life of the jaw dies; ⑤ The fitting surfaces on all of our jaws are machine finished to ensure the best possible fit; ⑥ We provide more

Learn MoreSearch HSN code for Jaw Plate in India - Export Genius

Find jaw plate HS code in India. 8431, Parts suitable for use solely or principally with the machinery of headings 8425 to Indonesia · list box

Learn MoreJAW PLATES - Precision Casting

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing

Learn MorePDF) Optimum design and analysis of (the) swinging jaw

The interaction between jaw plates and material particles brings the inevitable and serious wear to the jaw plates during the jaw crusher

Learn Morejaw | anatomy | Britannica

jaw, either of a pair of bones that form the framework of the mouth of vertebrate animals, usually containing teeth and including a movable lower jaw (mandible) and fixed upper jaw (maxilla). Jaws function by moving in opposition to each other and are used for biting, chewing, and the handling of food. The mandible consists of a horizontal arch, which holds the teeth and

Learn MoreJaw Plates | High Quality Fixed & Swing Jaw Spares | GTEK

Description Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn Moremantle and bowl liner | mention the purpose of jaw plates

Mantle and Bowl Liner for Mesto Cone Crusher. Author:xixi Addtime:2018-07-25 Click: Product description: 1. Mesto Cone and Jaw crusher spares and wear parts Cast Iron Bowl Liner Cone Mantle. Saksham Casting - Offering Cast Iron Bowl Liner Cone Mantle at Rs 110/kg in Palwal, Haryana. Read about company. Get contact details and address | ID:

Learn MoreCrusher Jaw Plate Latest Price, Manufacturers & Suppliers

Find here Jaw Plates, Crusher Jaw Plate manufacturers, This product is manufactured by making use of quality stainless steel or manganese, obtained from

Learn More

Leave A Reply