TLC for Primary Crushers | E & MJ

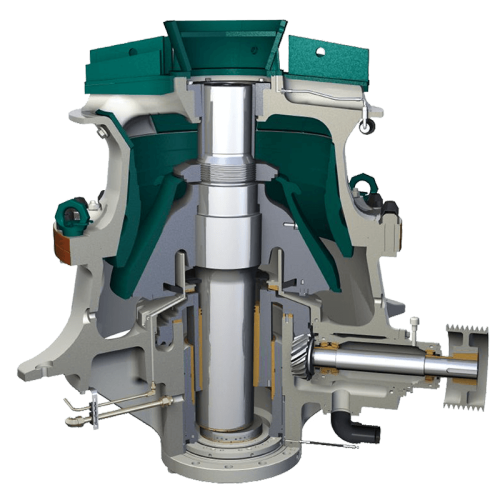

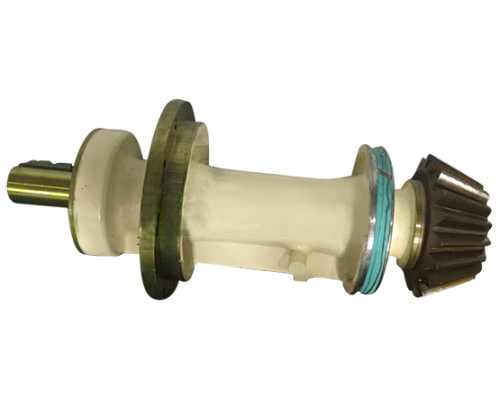

Primary gyratory crushers are easily the hardest working piece of fixed plant on a mine site. The gateway between extraction and processing, they bear the brunt of continuous operation, high feed volumes, and are subject to rock particles of extreme size variation and hardness. It is therefore vital that they are kept in top condition

Learn MoreExamples Of Primary Crusher

material crushed in an impact crusher is an example of dynamic impact. when the material is crushed in an impact crusher, the freely falling many times, rotary breakers are used as primary crushers and ring granulators are used as secondary crushers. information on construction and working of various crushers is given in the following chapters.

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

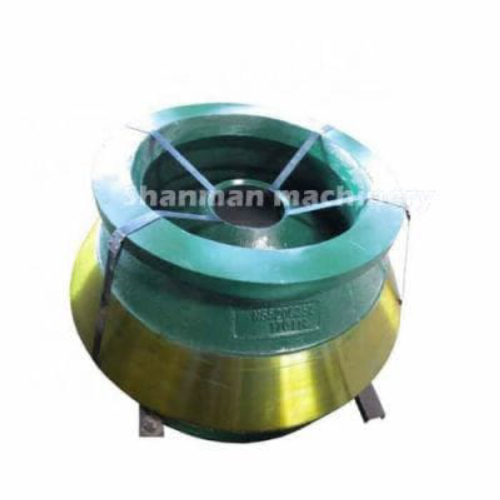

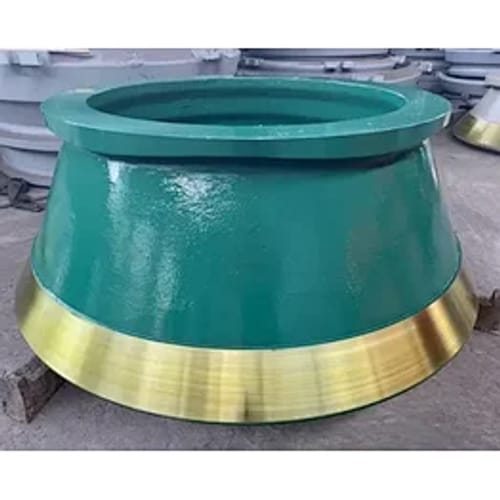

5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described as a cone crusher. The larger crushers are normally known as primary crushers as they are designed to receive run-on-mine (ROM) rocks directly from the mines.

Learn MoreThe Effects of Accelerated Blast Timing on Primary Crusher

3/19 · Orica Quarry Services currently supplies a Rock on Ground (ROG) blasting service at Mawsons Lake Cooper Quarry, with the aim of this trial being to initiate a blast using accelerated timing and determine if measurable and significant production improvements could be delivered. On 29 April, , a 45,000 tonne trial blast was fired.

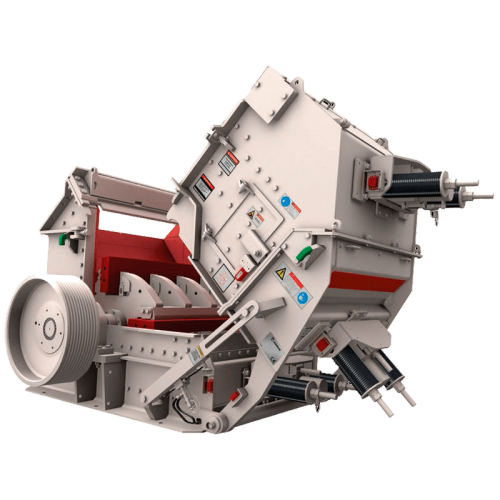

Learn MorePrimary Impact Crushers | FABO Machinery

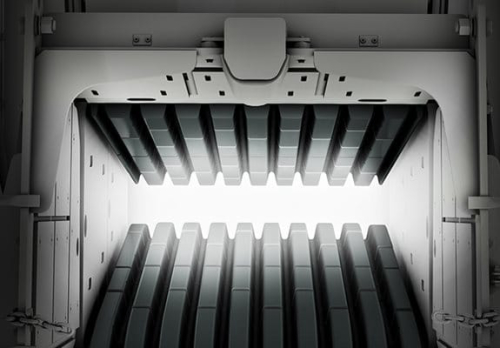

Primary Impact Crusher. Fabo Primary Impact Crushers lower the secondary crushing requirement, provides a high level of reduction ratio and help to increase the plant production capacity to its highest level while processing materials with moderate or low abrasiveness. These machines are produced in two different types according to usage

Learn Moreexamples of primary crusher

Primary crushers with crush run-of-mine rock from blast product size to what can be carried by the discharge conveyor or fit/math the downstream process A typical example of primary crushing is reducing top-size from 900 to 200 mm In Selecting a primary crusher you need to ,

Learn MoreExamples Of Primary Crusher In The Philippines

Jaw Crusher For Sale In Philippines Click For Price List. Small type jaw crusher for sale pe150250 pe500750. the output of this small jaw crusher 40110th, the maximum feed size 425mm, and the discharging granularity 50100mm. it is suitable for primary and secondary crushing of all kinds of minerals and rocks, withrushing strength not exceeding 320 mpa.

Learn MoreFourth Amended and Restated Primary Care Accountable Care Organization

special needs of those who, for example, are visually limited or have limited reading proficiency. Examples of Alternative Formats shall include, but not be limited to, Braille, large font, audio tape, video tape, and Enrollee Information read aloud to an Enrollee by an Enrollee services representative. Alternative Payment Methodologies (APMs)

Learn Morechapter 14. aggregate production - Assakkaf

A primary crusher receives the stone The output of the primary crusher is fed to a secondary crusher, which further Example 1 (cont'd).

Learn Moreexamples of primary crusher

Primary crushers with crush run-of-mine rock from blast product size to what can be carried by the discharge conveyor or fit/math the downstream process A typical example of primary crushing is reducing top-size from 900 to 200 mm In Selecting a primary crusher

Learn MoreCrushers I manufactor | thyssenkrupp Mining Technologies

Primary crushing. In primary crushing larger run-of-mine materials, for example rocks or ore lumps are reduced to smaller fragments. If not

Learn MorePrimary Crushing Plants | Hazemag North America

Primary crusher options: impact crushers, hammer crushers, sizers & impact roll crushers Generation of a product ideal as feed material for vertical roller mills and ball mills Consistent high product quality Reduction on crusher load through pre-screening by

Learn MoreType of crushers and their difference - JXSC Mining

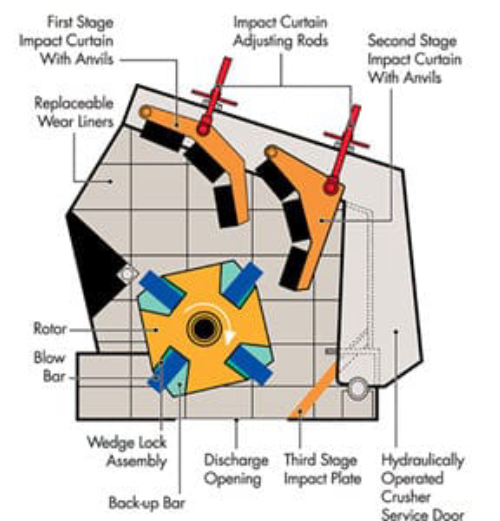

12/10 · There are two types of impact crushers: horizontal shaft impactor and vertical shaft impactor. Impact crushers are suitable for materials that are soft or easily cleaving from the surface. The crusher consists of a fast spinning rotor and beaters attached to the rotor. The feed is entering to the crusher from the top and crushing starts

Learn MorePrimary Crusher Definition | Law Insider

Define Primary Crusher. Be qualified to operate the primary gyratory crusher and perform all related job functions. Be qualified to operate Heavy Duty Haul Truck (Cat. Service or rock trucks trucks or equivalent). Laborer: Entry level position. Be qualified to perform clean up and general pit duties. Become trained as a Heavy Duty Truck Operator and/or as a Primary Crusher Operator.

Learn MoreP&Q University Lesson 7- Crushing & Secondary Breaking

For example, a grizzly feeder can be wider than the hopper, and the crusher inlet wider than the feeder. The discharge chute under the crusher is 4 inches wider than the inner width of the crusher, and the subsequent discharge belt is another 4 inches wider than the discharge chute.

Learn MorePerfecting the Performance of Secondary Crushers | E & MJ

For example, in a simple arrangement, if the primary crusher produces a high quantity of fines, then more material is screened out and less material is fed

Learn MoreTypes Of Crusher - Working Principles of Crushers - Fabo

For example, in the mining industry, it is generally necessary to use a primary crusher and a secondary crusher first, and then a third or fourth type

Learn MoreExamples Of Primary Crusher

May 06, Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher. After receiving the primary crusher crush the material and produce a new fresh reduced size of the source material. The primary crusher has only functioned up to that point. A secondary crusher comes into action and further reduces the size.

Learn MorePrimary Crusher Foundation Drawings Sample

5.1 introduction. gyratory crushers were invented by charles brown in 1877 and developed by gates around 1881 and were referred to as a gates crusher [1]. the smaller form is described as a cone crusher. the larger crushers are normally known as primary

Learn MoreSecondary Crushing Equipment - Mineral Processing & Metallurgy

These big machines were designed to operate at rather coarse discharge settings, usually from 10 to 12″, and the usual practice was to follow them with gyratory crushers such as the No. 9 (21″)' or No. 10 (24″), the over-all ratio-of-reduction for the two machines being 14 or 15 to 1.

Learn MoreAnta Raxia Pepper Grinder,Pill Crusher Mortar | Wayfair

Pepper Grinder,Pill Crusher Mortar. See More by Anta Raxia. 0.0 0 Reviews. $65.99 $111.99 41% Off. $40 OFF your qualifying first order of $250+1 with a Wayfair credit card. Ship to: 67346 - Grenola. Add to Cart.

Learn MoreUnderstanding the Different Types of Crushers | Agg-Net

More on Aggregate Crushers · Jaw crushers. A jaw crusher is a compression type of crusher. · Cone and gyratory crushers. Cone crushers and gyratory crushers are

Learn MoreCrushers - an overview | ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is

Learn MoreCrusher Selection And Types of Crusher - Engineering Intro

Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher. After receiving primary crusher crush the material

Learn MorePDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

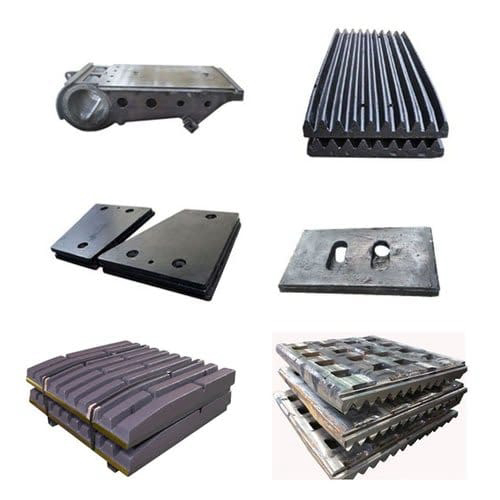

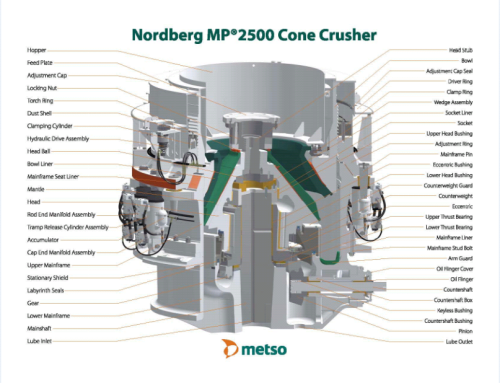

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

Learn MoreConstruction, Working and Maintenance of Crushers for

For example, jaw crushers using this method of compression are suitable for For primary crushing with a reduction ratio of 6 to 1.

Learn MoreCrusher - Wikipedia

Blake crusher-the swing jaw is fixed at the lower position · Dodge crusher-the swing jaw is fixed at the upper position · Universal crusher-the

Learn MoreRight Primary Crusher for Aggregate Projects | Oreflow Australia

A primary crusher plays an important role in a mineral processing plant. It reduces the size of large rocks wherein the smaller pieces are

Learn MorePrimary Crusher Example Manufacture and Primary Crusher

China Primary Crusher Example Manufacture, Visit Here to Find the Primary Crusher Example That You are Searching for. Shenyang Sanland Mining Equipment Manufacture Co., Ltd.

Learn MoreDifferent Types Of Crushers Machine Of Primary,secondary And Tertiary

Examples of primary crushers are jaw crusher; Gravel crushing process,Gravel crusher, for sale,equipment Rock is crushed in two or three different phases: primary, secondary and for secondary and tertiary crushing. crushers crush all types of rock but Stone crusher machine for sale used for crushing plant in India

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

Of all primary crushers, the impactor is the crusher that gives the best cubical product. Intermediate crushing Intermediate crushing with different types of crushers The purpose of intermediate crushing is to produce several coarse-grade products - for example, road base aggregates - or to prepare material for final recrushing.

Learn More

Leave A Reply