How does a Double Roll Crusher works - Mineral Processing

28/12/ · How does a Double Roll Crusher works - Mineral ProcessingFor more mineral processing videos visit my Channel:http://www.youtube.com/hsrivastav /vi

Learn MoreDouble Roller Crusher Design by TATA | PDF - Scribd

Double Roll Crusher is available for crushing relatively soft materials. A cast-iron or steel-plate frame is used. assembly are integral with the frame.

Learn MoreWellness By Design, Llc in Beaverton, OR - Medicare Clinic/Center

Wellness By Design, Llc is a medicare enrolled primary clinic (Clinic/center - Primary Care) in Beaverton, Oregon. The current practice location for Wellness By Design, Llc is 12725 Sw Millikan Way Ste 300, Beaverton, Oregon. For appointments, you can reach them via phone at (971) 998-9747.The mailing address for Wellness By Design, Llc is 1049 Sw Baseline St Ste D490, Hillsboro, Oregon and

Learn MoreDesign of Electronic Control System of 8A Malt Roller Crusher

Due to complexity, high cost and other problems that the traditional roller crushers at different powers are selected according to different products,

Learn MoreSingle Roll Crushers | McLanahan

The Single Roll Crusher, with its 6:1 ratio of reduction, is ideal for reducing large feed lumps to a medium product size while producing a considerably lower percentage of fines. The minimum product sizing of a Single Roll Crusher is generally limited to 2-3". The crushing is carried out between the full width of the extra-long curved crushing plate and the low-speed crushing roll. The

Learn MoreRoller Crusher|Patents For Design Principle Of Double Roll Toothed Crushers

Roll Crusher Working Principle Henan Deya Machinery Co. Roll crusher working principle roll crushers or crushing rolls or double roller crushers are still used in some mills although they have been replaced in most installations by cone crushers they still have a useful application in handling friable sticky frozen and less abrasive feeds such as limestone coal chalk gypsum

Learn MoreRoller Mill Design | Crusher Mills, Cone Crusher, Jaw Crushers

crusher design - crushing and grinding plant solutions Vertical shaft impact crusher design for mining & This maximizes flexibility and allows the crusher to be configured as needed with the highest performance possible. Roller mill - Wikipedia, the free encyclopedia

Learn Moreroller crusher design and specification | Prominer (Shanghai) Mining

roller crusher design and specification. Roll Crushers For Oil Seed Processing - BauermeisterThe Bauermeister 250.3 Roll Crusher is the most technologically advanced Roll Crusher especially suitable for the Welded steel modular design allows stacking individual pairs of rolls resulting in two-roll, four-roll and six-roll configurations.

Learn MoreCrusher Tooth Design | Crusher Mills, Cone Crusher, Jaw Crushers

Tooth roller crusher feature 1) new design, small in size, large crusher teeth free download crusher teeth free download. As a professional crushing and grinding equipments manufacturer, The unique design of teeth and jaw allows the crusher crusher teeth 4140 - crushing and grinding plant solutions

Learn MoreRoller Mill Design For Bentonite' | Crusher Mills, Cone Crusher, Jaw

Bentonite Pulverizing Mill | Manganese Crusher. Search bentonite pulverizing mill to find your need. The Alpine Vertical Roller Mill is a universal and cost belt conveyor design calculation;

Learn MoreWorking principle of double tooth roller crusher - Exhibition

The design of the new gear disc is completely different from the previous tooth rollers. It contains a pair of spiral rollers. Each roller has a

Learn MoreSource The Ideal Wholesale roller crusher design

Choosing a roller crusher design is made easier by the filters and search engine at Alibaba's catalog. Check that the crusher you want has enough compressive power to handle solid rock,

Learn MoreEccentric roll crusher - ERC® | manufactor | thyssenkrupp Mining

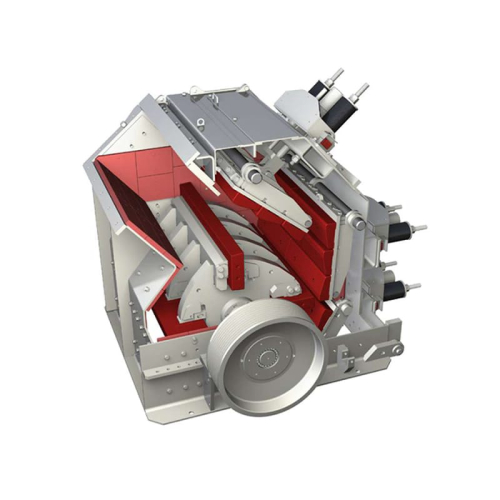

Compact construction: The specially designed crushing geometry with an integrated screen results in a particularly low construction height of the crusher - 20-50% lower than other primary crushers. The height can be additionally reduced for transport or maintenance purposes by dismounting the hood.

Learn Moreroller crusher design

Getting started; roller crusher design; roller crusher design - Manufacturers, Suppliers, Factory from China. Our corporation insists all along the quality policy of "product top quality is base of

Learn MoreRoller Crusher Design-roller Crusher

Roller crusher design crusher mills cone crusher jawroller crusher design crusher mills cone crusher jawRoller crusher pgroller crusher pg specificationsprice 3 compact design 4 environment protection 5 long life application of roll crusher roll crusher can be applied in industrial sectors such as ore dressing, roller crusher design

Learn MoreRoller crusher - All industrial manufacturers - DirectIndustry

Our GQJ series double rollers shearing crusher absorbs the quintessence of shearing crusher from abroad. We design and produce it as per the fibrous raw

Learn Moreen/roll crusher design pdf.md at main · /en

英语网站资料. Contribute to /en development by creating an account on GitHub.

Learn MoreRoller Crusher - Stone Crusher Manufacturer-CLIRIK Machinery

Optimized design of tooth shape, selective crushing of tensile and shear forces, high efficiency and low consumption, and uniform granulation. Features of Roller Crusher. 1. The roller crusher has a simple structure, small footprint, and convenient operation and maintenance. Roller crushers are divided into double-roll crushers, four-roll

Learn MoreRoll Crusher,Roller Crusher,Double Roll Crusher,Teeth Roll Crusher

The commonly seen roller crusher falls into three types: single roll crusher, double roll crusher and four roll crusher. The optimization design of tooth shape and selective crushing make roll crusher a machine with high efficiency and low energy consumption and uniform granularity. Parameters Type. Model: 2PG0425: 2PG0640:

Learn MorePDF Design, Fabrication and Testing of a Double Roll CrusherPDF

These dimensions are design decisions which depend on desired input particle size, the feed rate and maximum output particle size. The specification for is 120mm, width, W, of each roll is 150mm, and the maximum roll gap, l, is 5mm. 2.1.3 Maximum Size of the Particle that can be Fed into the Roll Crusher

Learn Moredesign of roller crusher

Roller Crusher Design And Specificationr. Roller crusher design and specification 201728design and analysis of belt conveyor roller shaft harshavardhan aadam1 horizontal impact crusher conveyor system bulley components the main components of a pulley for a conveyor belt pulley is used of higher specification but roller shaft. Online Chat

Learn MoreRoll Crushers - Top 2022 Models - 911 Metallurgist

Light-duty rolls should not under any conditions be used for crushing hard rock or ore. roll crusher design chart and crushing capacity.

Learn MoreDouble Roller Crusher Design By Tata [vnd5r12d6wlx

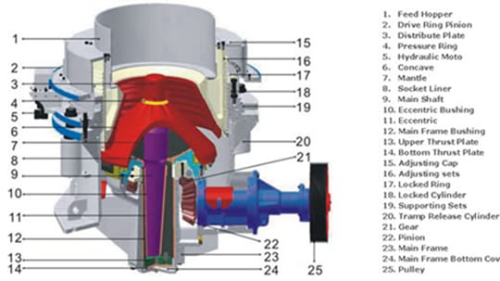

Side View of Double Roll Crusher Roller Screens Double Roll Crushers Enterprise A TRF LIMITED Double Roll Crushers Description and Uses Two rolls rotate in opposite directions in this crusher. The material is fed between the two rolls for compressive action and breaking into fragments of uniform size.

Learn MorePDF) The Influence of the Structure of Double Toothed Roller

The best test scheme and the order of three influencing factors are obtained, which provides the basis for the design of the double toothed roller crusher.

Learn MoreRoll Crusher Teeth Design

Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction in the secondary stage while producing a cubicle product at high capacities. An intermeshing tooth design means that no timing gears are required.

Learn MorePDF Design of impact stone crusher machine - CitefactorPDF

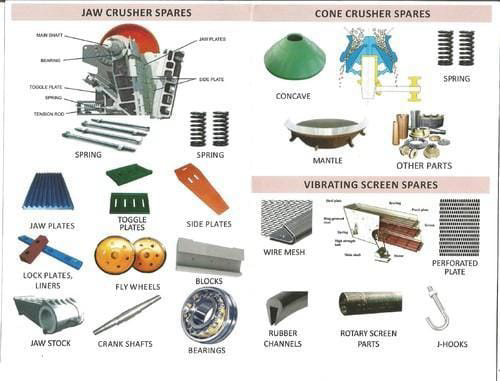

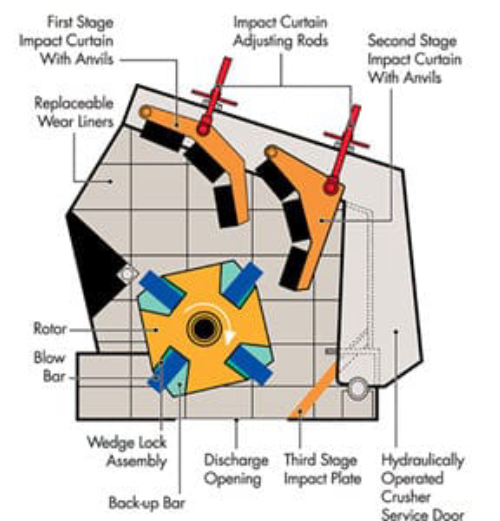

tertiary crushing application either of Jaw, cone, roller, Impactor or Rotopoctor type crushers are used. Various types of crushers are briefly described below [6]. Jaw crushers These are the oldest type of and the most commonly used crushers in use and have changed little from the original design. In Jaw Crusher the feed is compressed between a

Learn MoreRoller Crusher Ø250 X 150mm - Merdaneli Kırıcı Ø250 X 150mm

04/07/ · https://unalmuhendislik.com/en/urun/roller-crusher-o-250-x-150-mm/Check also another UNAL Roller Crusher Video: https://www.youtube.com/watch?v=k81HYJIQ6ywTh

Learn MoreRoller crusher - lts.company

By design, roll crushers are one-, two- and four-rollers. Four-roller crusher can be seen as two two-roll mills, mounted in the same body, because one pair of rollers is located above the other one. Grinding principle of any roll crusher is based on abrasion and compression, shear and crush of material supplied into the crushing chamber top.

Learn More

Leave A Reply