Different types of concrete batching plant models

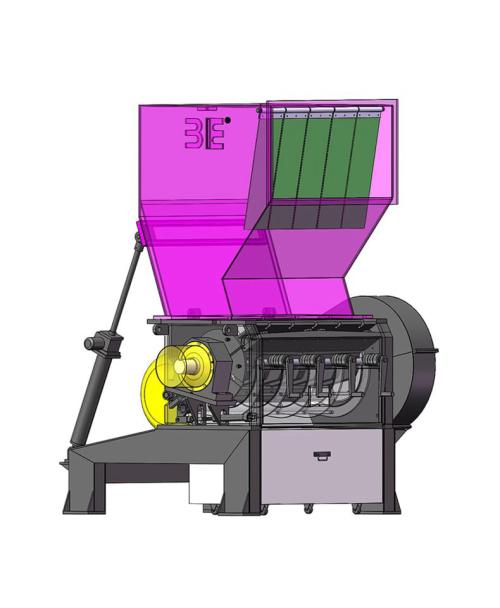

6166. Concrete Batching Plant. Concrete batching plants are used to combine coarse aggregates, sand, cement, water, crushed stone and other admixture to produce homogenous concrete. The batching process improves the quality of concrete. A batching plant consists of a variety of parts and machines: mixer unit, conveyors, aggregate and cement

Learn MoreClinker Cooler, Cement Cooler, Grate Cooler | Clinker Production

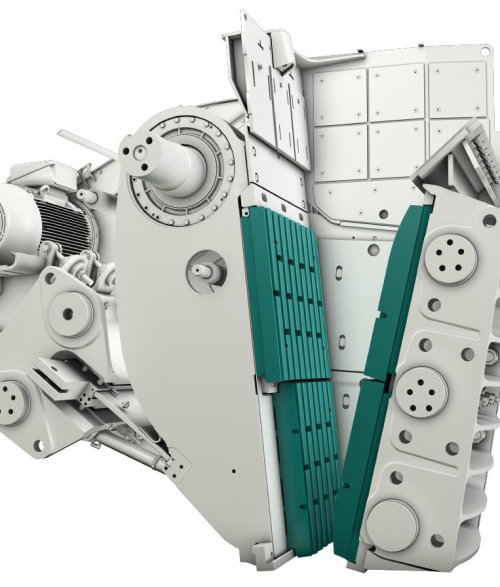

At present, the common types of clinker cooler include single cylinder clinker cooler, mutiple cylinder cooler and grate cooler. The traditional grate cooler can be divided into rotary cooler, vibrating clinker cooler and push clinker cooler. The grate bed is the core part of grate cooler.

Learn Moretypes of cooler used in cement plant - Products

Cement Kilns: Grate Coolers. Bucket Grate Coolers The first form of grate cooler used on British kilns was the Bucket Grate. The cooler was built into a greatly-enlarged kiln hood, with

Learn MorePERFORMANCE EVALUATION OF A GRATE COOLER IN A

International Journal of Scientific Engineering and Applied Science (IJSEAS) – Volume-4, Issue-03, April ISSN: 2395-3470 www.ijseas.com 2 2.0 EQUIPMENT DESCRIPTION 2.1 Cooler: This serves a most daunting but very important role in the cement production. The proper or improper cooling mostly determines the type and level of compressive strength

Learn MoreCement Cooling System - Efficient, Industrial Cement Cooler

High-efficiency cement cooling The Solex heat exchanger is capable of handling any relatively free-flowing powder or crystalline bulk solids, making it the perfect candidate to cool cement, while using up to 90% less energy compared to direct cooling methods.

Learn MoreCement Cooling System - Efficient, Industrial Cement Cooler | Solex - Solex

Cement High-efficiency cement cooling The Solex heat exchanger is capable of handling any relatively free-flowing powder or crystalline bulk solids, making it the perfect candidate to cool cement, while using up to 90% less energy compared to direct cooling methods.

Learn MoreClinker Grate Cooler for Cement Plant

The traditional coolers are divided into3 types: rotary type, vibrating type and push type. However, since the first two types have been eliminated, the push type grate cooler has become the main cement clinker cooler model selected for the decomposing kiln outside the kiln. .

Learn MoreHow Does Clinker Cooler Reduce Cement Production ... - AGICO Cement Plant

The main power consumption of a clinker cooler is its cooling fans. It usually takes 1.9-2.3 m 3 under standard conditions to cool 1 kg clinker from 1400 ℃ to 65 ℃, and the power consumption of the whole system is about 7 kWh. If the air consumption per kilogram of clinker cooling is reduced from 2 m 3 to 1.7 m 3, the air consumption efficiency will be 15% lower than that of

Learn MoreGrate Cooler in Cement Plant | Cement Clinker Cooler

The grate cooler can be further divided into three types: the rotary grate cooler, the traveling grate cooler, and the reciprocating grate cooler. The first two have already been eliminated

Learn MoreCN212457959U - Improved grate type cooler for cement plant

The utility model discloses an improved generation comb formula cooler is used in cement mill, including the box, the discharging pipe has been run through in the left side of box, and the right-hand member of discharging pipe runs through the box and extends to the inside of box, and the first driving motor of support frame fixedly connected with is passed through at the top of box

Learn MoreLatest cooler types in cement plant - Consuol Mining Machinery

A huge development has happened in clinker coolers designs and types as well. Grate cooler with a take-off for pre-calciner is generally required for pre-calciner kilns. Cross bar coolers are used in new plants to achieve cooling efficiencies ( 70%) and less maintenance burden. New coolers are designed for the capacity to be handled with the

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant Equipment

According to the movement mode of the grate, the grate cooler can be divided into three types, rotary type, vibrating type, and push-type grate cooler, with the development of cooler technology, push-type grate cooler is considered as the most common clinker cooler in the cement production line. Structure of grate cooler

Learn MoreCement Plant Process and Instruments Used - SlideShare

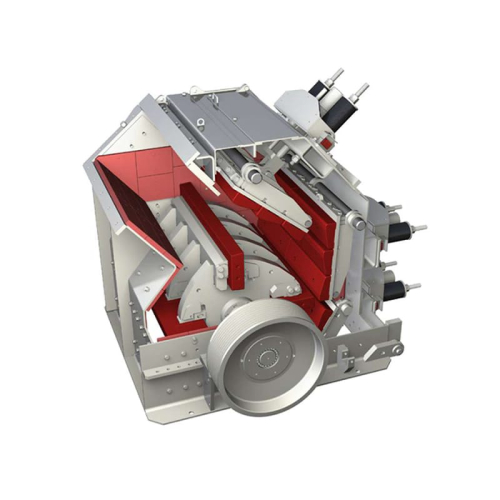

A brief presentation on Cement Plant Process and Instruments Used in Cement Plant. In the two stage crushing system, a impact type crusher is used in the first stage for raw crushing, followed by hammer crusher in the second stage. The Grate cooler operates with crosscurrent principle in which the clinker is moved across the grate while

Learn Moreclinker cooler in cement plant in usa 35 m/h small professional

How does the Concrete mixing plant works. Concrete mixing plant is divided into four parts: gravel feed, powder (cement, fly ash, bulking agents, etc.) to feed, water and feed additives, transmission and storage stirred their workflow shown in Figure 1. , the mixer control system power, into the human – machine dialogue operation interface, system initialization process,

Learn MoreGrate Cooler – Clinker Cooler | AGICO Grate Cooler In Cement Plant

Grate cooler, as a quench type clinker cooler, is the important cement equipment in the clinker calcination system. Its main function is to cool and transport cement clinker. Meanwhile, provide hot air for cement rotary kiln and precalciner.

Learn MoreClinker Production - Clinker Manufacturing | Cement Manufacturing Machines

Cement kiln is the main equipment for clinker sintering. From structure, it can be divided into rotary cement kiln and shaft kiln, while, from the working principle, it can be divided into the dry method and wet method kiln. AGICO offers different types of cement kilns from 10-5000t/d with steady running, high efficiency and large output.

Learn Moretypes of cooler used in cement plant

Portland cement plants can be used without or CS in cement chemist notation 2) and rankinite (C 3 S 2 distinct types of coolers in use in cement plants: Cooling tower - Wikipedia If that same plant had no cooling tower and used once-through cooling water, fluid coolers (or closed circuit

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

10 rows · The grate cooler is a quenching type cement cooler apply for the cement manufacturing

Learn MorePDF Performance Evaluation of A Grate Cooler in A Cement Manufacturing ...PDF

International Journal of Scientific Engineering and Applied Science (IJSEAS) - Volume-4, Issue-03, April ISSN: 2395-3470 www.ijseas.com 2 2.0 EQUIPMENT DESCRIPTION 2.1 Cooler: This serves a most daunting but very important role in the cement production. The proper or improper cooling mostly determines the type and level of compressive strength

Learn MoreTypes Of Cooler In Ultratech Cement Plant Crusher

Types Of Cooler In Ultratech Cement Plant. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment.

Learn MoreRotary Cooler for Small Cement Plants | Rotary Drum Coolers | AGICO

Rotary coolers are a type of traditional cooling equipment in cement plants. They perform especially well on cement clinker cooling in small-scale clinker production lines and mini cement plants.

Learn MoreRotary Cooler - Cement Cooler | AGICO Cooler In Cement Plant

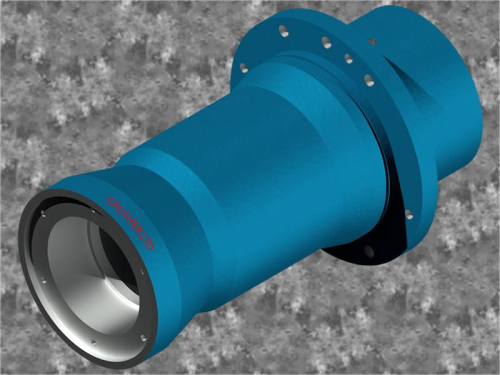

Rotary cooler is also called clinker cooler, which is the important support equipment of cement rotary kiln. It is mainly used to cool the high-temperature clinker(1000-1200℃)discharged from the rotary kiln into an appropriate temperature (less than 200℃). The cold air produced by it contact countercurrent with the clinker in the

Learn MoreThe impact of cooling water types on the cement clinker properties

The area under study is El-Minia white cement plant which locates at Bani Khaled, Samalout, El-Minia Governorate. The plant includes industrial processes related to the production of white cement. It is using Nile water at different processes such as cooling clinker in the rotary cooler and at grinding cement through a ball mill.

Learn MoreAutomatic cement rotary cooler use in cement plant

Rotary Kiln - GGBS&Cement Plant,cement grinding mill,vertical. Rotary Kiln is a kind of thermal equipment calcines lump, bulk and slurry materials. It is widely used in cement & construction, non-ferrous metals, lime, ferrous metals, refractory materials, industrial chemicals, paper making industries etc. Features & Advantages. 1.

Learn Moreclinker cooler in cement plant in usa concrete drill bit types parts

How does the Concrete mixing plant works. Concrete mixing plant is divided into four parts: gravel feed, powder (cement, fly ash, bulking agents, etc.) to feed, water and feed additives, transmission and storage stirred their workflow shown in Figure 1. , the mixer control system power, into the human - machine dialogue operation interface, system initialization process, including recipe

Learn Moretypes of klinker cooler in cement

The grate cooler is a quenching type cement cooler apply for the cement manufacturing plant.According to the movement mode of the grate, the grate cooler can be divided into three types, rotary type, vibrating type, and push-type grate cooler, with the development of cooler technology, push-type grate cooler is considered as the most common

Learn MoreRotary Cooler for Small Cement Plants | Rotary Drum

Rotary coolers are a type of traditional cooling equipment in cement plants. They perform especially well on cement clinker cooling in small-scale clinker production lines and mini

Learn Moretypes of cooler used in cement plant

What are the differences in these cement types and how are they tested, produced, and identified in practice? types of cooler used in cement plant. types of cooler used in cement plant. Cement Plant Process & Equipments 201659-Cement Plant Manufacturers & Gears Manufacturers Understanding.In its simplest form, the rotary kiln is a .dropping out

Learn MoreGrate Cooler in Cement Plant | Cement Clinker Cooler for Sale

The grate cooler can be further divided into three types: the rotary grate cooler, the traveling grate cooler, and the reciprocating grate cooler. The first two have already been eliminated from the industry; the reciprocating grate cooler is the mainstream clinker cooling equipment in most cement plants today.

Learn MoreClinker Production - Clinker Manufacturing | Cement

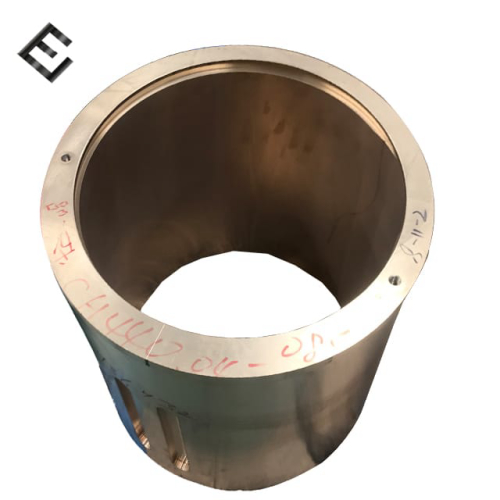

Clinker Cooler Clinker cooler is also called cement cooler, which set behind the cement kiln for clinker cooling. In cement plants, we usually adopt the rotary cooler and grate cooler for daily production. Inside the cooler, hot clinker will direct contact with the cooled air blown from the air blower to realize fast cooling. Clinker Cooler

Learn Morecooler in cement plant

The grate cooler is a type of clinker coolers, it plays an important role in the clinker manufacturing process The grate cooler in a cement plant cools and transports the cement clinker from the rotary kiln, and provides heating air (secondary air) for the rotary kiln and preheaterThe performance of the grate cooler will directly affect the

Learn More

Leave A Reply