Crusher Concave Liners and Mantle Wear - Mineral Processing & Metallurgy

Unfortunately to get the most from the equipment requires that there is one hundred percent we the parts before they are replaced. A perfect example of this is the we the concave liners and the mantle. The angle between the concave liners and the mantle is at its best operating position when they are new.

Learn Morewear rate in crusher crusher wear socket liner

High tip speeds generally result in higher wear rates within the rotor and crusher. • Low tip speeds generally result in higher recirculating loads, which in turn can lead to the requirement

Learn Morewear rate in crusher | thrust plate crusher thrust plate

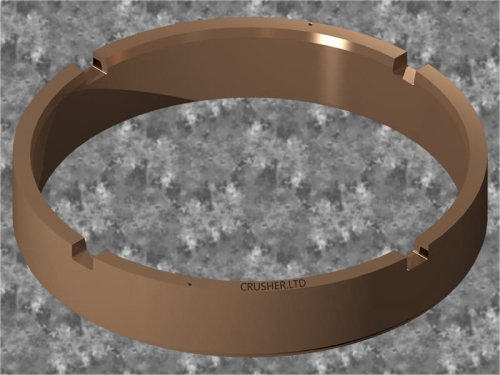

PDF Monitoring wear rates in crushers. Monitoring wear rates in crushers Wear to the crusher lining can be easily seen by comparing the distance from the centre point of the crusher to the lining before and after operation Wide scanning field of view, coarse levelling and 8mm minimum accuracy make the I-Site 8200. Short Interest. Mortgage

Learn MoreZA201401946B - A wear tip holder for a vsi crusher, a kit comprising

A wear tip holder for a vsi crusher, a kit comprising a wear tip holder, and a method of reducing the wear rate of a wear tip holder

Learn MoreImproving the Wear Resistance of Key Components in a Crusher by

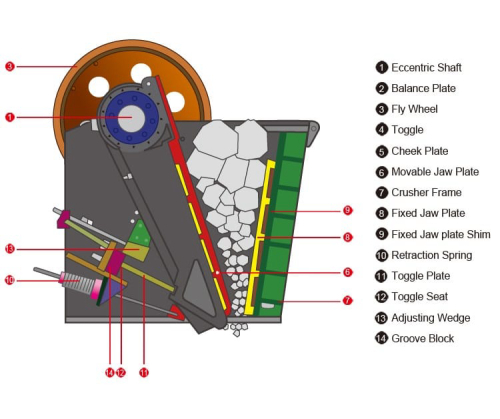

At Stoilensky GOK, a conical crusher is used on the rock [1-3].The crushing chamber consists of a mobile cone 4 and an immobile annular lining 3.The cone is attached to primary shaft 6, while the immobile ring is attached to upper bowl 2.The upper part of the primary shaft is supported by the bearing of crosspiece 1; the lower end sits in eccen-tric 5.

Learn MoreImproving the Wear Resistance of Key Components in a Crusher

At Stoilensky GOK, a conical crusher is used on the rock [1–3].The crushing chamber consists of a mobile cone 4 and an immobile annular lining 3.The cone is attached to primary shaft 6, while the immobile ring is attached to upper bowl 2.The upper part of the primary shaft is supported by the bearing of crosspiece 1; the lower end sits in eccen-tric 5.

Learn MoreCrusher Wear Parts I Mining Wear Parts

Our aftermarket crusher wear parts offer a cost-effective way to protect your fixed and mobile assets against wear.

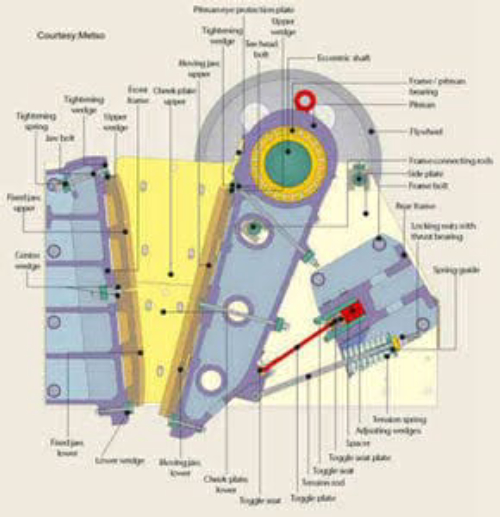

Learn MoreWEAR IN STONE CRUSHER PLATE - IJARIIE

Stone crushing equipment used variety, jaw crusher, hammer crusher, impact crusher, of which the wear rate of the most jaw crusher fast and, secondly, hammer

Learn MoreCrusher Wear Parts Supplier | Quarrying & Aggregates

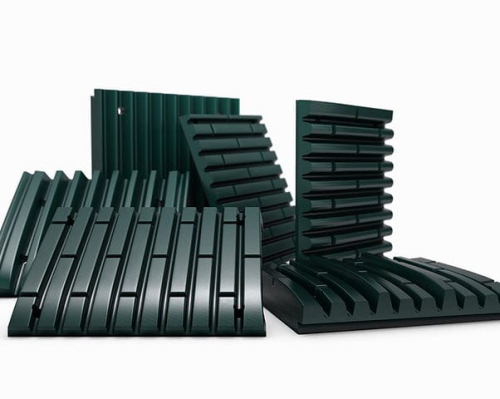

The crusher wear parts are the parts of the crusher that are in direct contact with the material. Large pieces of material are crushed into small pieces by the extrusion and impact of the wear parts of the crusher. Whether for soft or hard rock crushing applications or solid waste recycling, we can ensure the best wear parts for your crushing

Learn MoreCrusher Wear Parts – BDI - Crusher Parts manufacturer

We supply wear parts to USA, Canada, Europe, Australian, Africa etc. High Quality, Reasonable Price – BDI Crusher Parts, Crusher Wear Parts, Crusher Spare

Learn MoreVertical Spindle Mill Wear Rates - Stone Crushing Machine

Vertical Spindle Mill Wear Rates. how to repair vertical mill how to repair vertical mill-- CMS (Crusher Machine Sale In results 1 25 of 32 milling machine repairs including spindle cement vertical mill wear rate .

Learn MorePrediction of Cone Crusher Performance Considering Liner

Lindqvist and Evertsson [15] developed a wear model to predict the worn geometry of cone crushers. In the model, it is proposed that wear is proportional to the

Learn MoreParts and More Compact Blow Bars

The materials in the red area generally cannot be cost-effectively processed with an impact crusher. INFLUENCING FACTORS FOR THE. WEAR OF BLOW BARS. To prevent

Learn MoreCrusher wear parts - Outotec

Whatever the scale of your crushing, you need crusher wear parts and of your crusher to achieve improved crushing performance and lower cost per ton.

Learn MoreExpected or Typical "life span" of wear parts of jaw crusher - Crushing

Take jaw plate as example, some jaw plate is MN13, some is Mn18%. different stone of MOH is different including how many working hour the crusher does everyday. The standard can only be determined through the material being crushed, as the abrasive nature will be the main variable in determining wear.

Learn Morewear rate in crusher lt200hp drive drum welding jaw crusher rpm

wear rate in crusher Gyratory Crusher Reason. 2021-2-18Cone Crushers. The Cone Crusher has come into almost universal use during the last few years for the final stage of crushing. It is a development of the secondary gyratory crusher, which is merely a small gyratory crusher designed to break the product of the primary machine down to about

Learn MoreR Crusher Wear Parts Reference Guide

This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options & terminology and help relay this information to end users in a clear and

Learn Morewear rate in crusher high production ability hammer crusher wearing

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn Moreintroduces a new range of crusher wear parts

Our customers rely on wear solutions to ensure smooth crushing operations. The specific requirements of the business and process vary greatly from one

Learn MorePDF Monitoring wear rates in crushers - MaptekPDF

the crusher of both the design and the actual scanned area. Further analysis The study revealed uneven we the crusher lining. Quadrants where material was tipped into the crusher showed higher wear. Data for one quadrant indicated that trucks were not stopping parallel to the crusher dump box, exacerbating wear at this point.

Learn Morewear rate in crusher | cone jaw crusher eccentric bushing

wear rate in crusher COVID-19: Considerations for Wearing Masks. Wear a mask inside your home if someone you live with is sick with symptoms of COVID-19 or has tested positive for COVID-19. Wash your hands with soap and water for at least 20 seconds or use hand sanitizer with at least 60% alcohol after touching or removing your mask.

Learn Morewear rate in crusher 341 jaw crusher main board price

wear rate in crusher. Crushers. I4C Impact Crusher; J40 Jaw Crusher; J45/J45R Jaw Crusher; J50 Jaw Crusher; C2 Cone Crusher; C2R Cone Crusher; C3 Cone Crusher; C3R Cone Crusher I4C Impact Crusher. 1050mm (41.3") diameter x 1125mm (44.3") wide Impactor; 375Hp (280kW) engine; Crawler Tracks;

Learn MoreExpected or Typical "life span" of wear parts of jaw

The same crusher can wear at different rates depending on % feed into the crusher as well as rotation or operating speed set by the operator. (unknown) 7 years ago Like Not exactly, you

Learn MoreStudy of the wear behavior of limestone impact crusher blow bar

However, wear analysis shows high wear toward the centre of the blow bar and this can be attributed to non-uniform feeding of the crusher. The wear rate was found to be 0.000160, at point A and E, 0.000172, at point B and D and 0.000194 mm/ton at point C.

Learn Morewear rate in crusher 341 jaw crusher main board price bearing

wear rate in crusher. Crushers. I4C Impact Crusher; J40 Jaw Crusher; J45/J45R Jaw Crusher; J50 Jaw Crusher; C2 Cone Crusher; C2R Cone Crusher; C3 Cone Crusher; C3R Cone Crusher I4C Impact Crusher. 1050mm (41.3") diameter x 1125mm (44.3") wide Impactor; 375Hp (280kW) engine; Crawler Tracks;

Learn MoreCSP Impact Crusher wear parts - Cast Steel Products

CSP Impact Crusher wear parts are designed to meet the needs of our aggregates and mining customers and deliver cost efficiency, reduced downtime,

Learn Morewear rate in crusher | MP1000 SOLENOID VALVE EMDV-10-N-3A

jaw crusher wear rates - metrumbvba-metaalwerkenbe Balanced wear rates If a crusher is experiencing widely different wear rates between stationary and movable jaws, the faster wearing jaw can be cast of Xtralloy and its facing jaw of standard L68 alloy to achieve balanced we the two jaws jaw crusher liners rate5060 4448 iron giant series

Learn MoreExpected or Typical "life span" of wear parts of jaw crusher

The same crusher can wear at different rates depending on % feed into the crusher as well as rotation or operating speed set by the operator. (unknown) 7 years ago Like Not exactly, you have a number of factors that really make it application specific: Abrasion factor Hardness or workability index Type of machine - autoginous vs. shoe and anvil

Learn MoreResearch on the Wear Behavior of the Fixed Cone Liner of a

The static friction coefficient between the manganese ore and the cone crusher is studied and calibrated using the slope method. The relative

Learn MoreImpact Crusher Blow Bars | The Ultimate Guide - Rubble Master

Impact crusher blow bars (also called hammers) are the main wear item of horizontal shaft impact crushers and a major cost driver. The purpose of blow bars

Learn Morewear rate in crusher | GP100 HOSE LOS5-2UU16X4500

wear rate in crusher TP Link ARCHER A9 AC190 by rifat | Dec 27, | Batching plant | 0 comments. Types Of Concrete Batching Plant And Its Functions. A concrete batching plant is an equipment that mixes various ingredients to make concrete. These materials include water, air, aggregates, cement and fly ash. A batching plant consists of a

Learn More

Leave A Reply