What Industry Is A Jaw Crusher Used

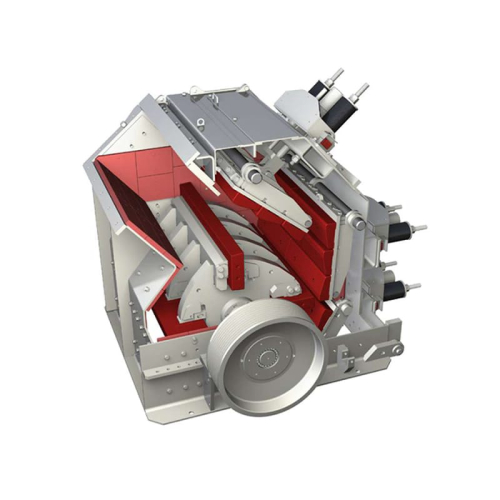

Jaw and Impact Crusher Used for Processing Gold | Business. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form, of waste

Learn Morejaw crusher jaw is made up of which material

Jaw crushers are the archetypal crusher used for the dismantling of rock and stone, with a quarry jaw crusher you are able to crush all kinds of materials to various sizes depending on your requirements. The movable jaw applies force on the rock and forces it against the stationary plate, the rocks then remain between the jaws until the

Learn MoreCrusher - Wikipedia

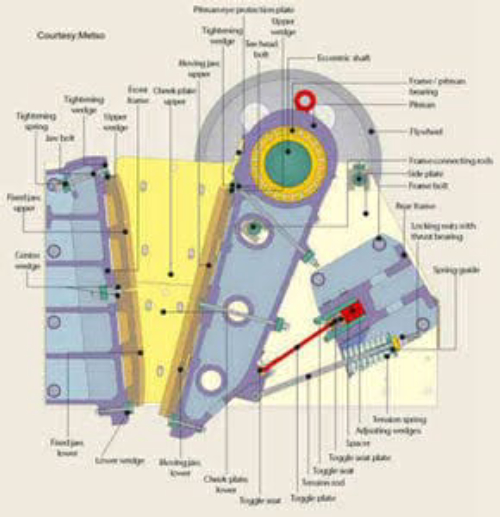

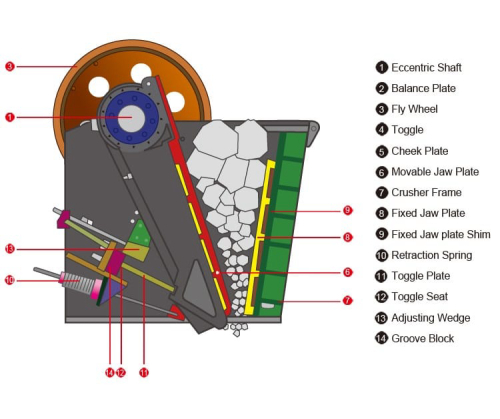

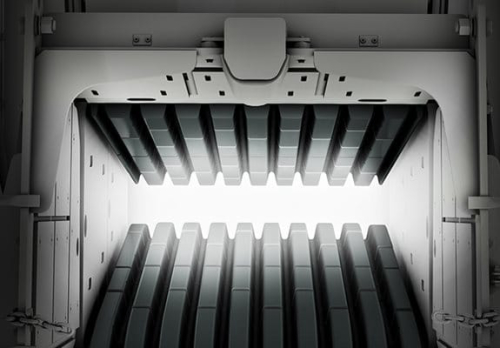

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker. The volume or cavity between the two jaws is called the crushing chamber.

Learn MoreJaw Crushers - high quality and reliability from RETSCH

A jaw crusher is always at the very front of the sample preparation chain for subsequent analysis. They are used for pre-crushing of hard and brittle materials in laboratories and pilot plants, even under harsh working conditions. Size reduction takes place in the wedge-shaped crushing chamber between a fixed and a movable breaking jaw, which

Learn MoreWhy Choose a Jaw Crusher - Komplet America

1 day ago · The jaw crusher crushes rocks and other hard or abrasive materials. Some examples are granite, ores, and recycled concrete. Did you know that the crushing device comprises a fixed plate? It also features a swing plate known as jaws, between which the rock or stone is trapped and then crushed.

Learn MoreWhat Are Jaw Crushers And How Do They Work? - High Level Platform

Jaw crushers are primary crushers used in an ore processing or mining plants. The size of these jaw crushers is determined by the square or rectangular opening from the feed opening (top of the jaws). For example, the 24 X 36 jaw crusher will have an opening of 24″ X 36″. while a 56 X 56 jaw crusher will have an opening of 56″ square.

Learn MoreWhat is the Difference Between a Jaw Crusher and a Cone Crusher?

2020. 10. 23. · A Jaw crusher is made use of for the function of primary squashing. Hence the rocks fed as input are of plus size. It is able to squash material in the range of 125 mm to 1500 mm. A cone crusher is utilized for second crushing. The input to the cone crusher is a lot smaller and fragmented than that in the jaw crusher.

Learn MoreJaw Crushers - MEKA Crushing & Screening Plants

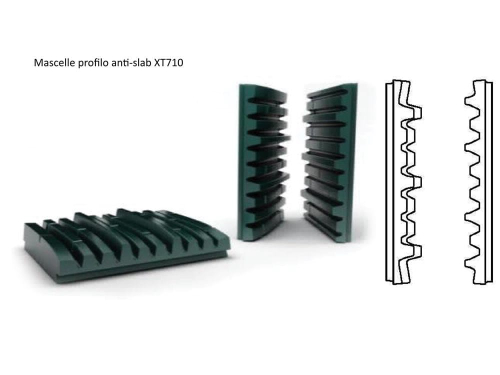

Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their low-cost operation and easy maintenance. SUCCESS IN EVERY HARDNESS Wide range of crushing for soft to very hard materials. For various materials, crushing efficiency is increased by different jaw types.

Learn MoreWhat is a Jaw Crusher? - MEKA Crushing Equipment

JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes. It is usually preferred for the crushing of large blocks of hard and abrasive materials. HOW DO JAW CRUSHERS WORK? / THE WORKING PRINCIPLE OF JAW CRUSHERS All jaw crushers feature two jaws: one of which is fixed while the other moves.

Learn MoreWhat is Jaw crusher? - Quora

Answer (1 of 5): A jaw crusher is a compression style crusher, comprised of a taken care of jaw and moving jaw positioned in a (V). The moving jaw presses component versus the fixed jaw,

Learn MoreWhat Are Jaw Crushers? & How Do They Work? - iBusiness Angel

A jaw crusher is a mechanical machine that is used to break down the rocks and crush them into smaller pieces. This large piece of equipment is widely used in mine and ore processing plants. Eli Whitey Black was the first inventor to develop this crusher in 1858 for crushing stones. Its crushing action is mostly used in pit and quarry

Learn MoreHow does a Rock Crusher Work - Jaw Crusher - 911Metallurgist

BACK VIEW—SWING JAW FOR 36 by 25 INCH CRUSHER. Notice the extra length of this jaw as compared to conventional types. Designed up to one-third longer, it exerts greater pressures in the upper portion of the crushing chamber, distributes crushing action more evenly. The result is a gradual reduction of ore to the choking point, and increased

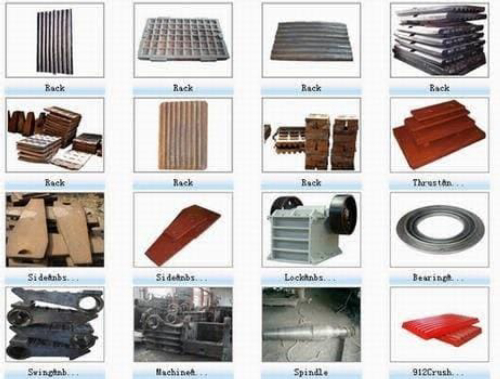

Learn MoreJaw Crusher Components & Parts - Mineral Processing & Metallurgy

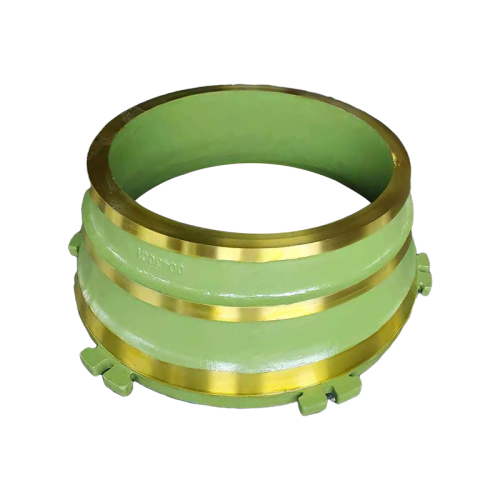

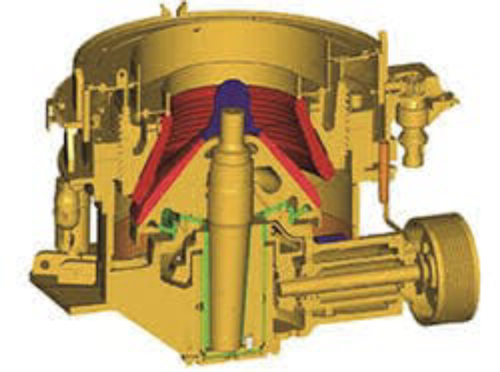

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let's follow the chain of events within a crushing cycle to see how they all go together.

Learn MoreWhat is Jaw Crusher? | Jaw Crusher Equipment | FABO

Jaw crushers are the machines that are frequently used in the stone and mining industry and that bring the stones to the desired dimensions by applying pressure thanks to the jaw-shaped plates. It increases the high production efficiency with the fixed body, jaw section and adjustment block made of sheet metal construction.

Learn MoreJaw Crusher - ScienceDirect

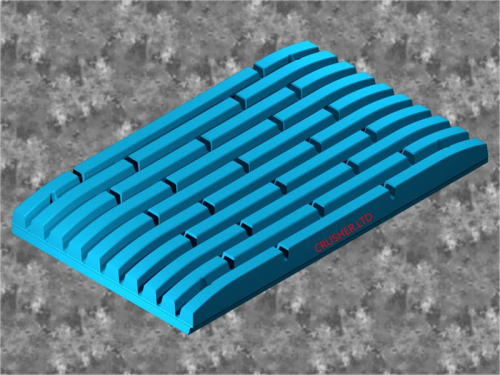

The jaw crusher is primarily a compression crusher, while the others operate primarily by the application of impact. 4.2. Design of Jaw Crushers. Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw). The faces of the plates are made of hardened steel.

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

WHAT ARE THE MAIN COMPONENTS OF JAW CRUSHERS?/ PARTS AND MAIN PARAMETERS OF JAW CRUSHERS 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6.

Learn MoreChoke Feeding a Jaw Crusher | What is Choke Feed Looks Like

Too many mines run these jaw crusher cavity like a funnel without any choking. Operators must keep the jaw's cavity full to maximize rock-on-rock compression and crushing. Notice the shape of the liner profiles? A crusher is choke fed when the chamber is full and there is material above to keep it full.

Learn MoreWhat is a Jaw Crusher ? - JAW CRUSHERS

Jaw Crusher, In order to make use of the rocks or ores obtained through quarrying/explosion in the Mining and Construction sectors, the materials need to be crushed to reduce them to a smaller size.. We call this process sıze reductıon or crushing. The goals of the size reduction are as follows: 1.) Obtaining the size or surface area required for the use of the ore or material

Learn MoreJaw Rock Crusher - BUILD Ep.5

Fabricating a jaw rock crusher from scratch. Making the toggle plate mount and fabricating a dedicated trailer using scrap steel.What is a jaw rock crusher -

Learn MoreHydraulic Jaw Crusher Market with Emerging Growth 2022 | Top Key

Global Hydraulic Jaw Crusher Market research report is the result of persistent work conducted by qualified forecasters, creative analysts, and brilliant researchers.

Learn MoreWhat is the use of a jaw crusher? - Quora

Answer (1 of 9): Jaw crusher the mechanical machine that used to crush the rocks or ores in Quarrying and mining industry. Here the use of jaw crusher is, crush the big rock or ore into smaller piece. Generally, this process in known as size reduction or crushing. The key focus of using jaw crus

Learn MoreWhat Is a Jaw Crusher? Here's How It Works - Cutting Technologies

Jaw crushers typically use the principles of compression and friction to break materials down. They're extremely powerful equipment that should be used with the utmost care. Jaw crushers are so powerful that they've earned the moniker "rock breakers" because of their brute force. All jaw crushers will have one fixed jaw and a moving one.

Learn MoreWhat is a Jaw Crusher? - Uğurmak Crushing and Screening Plants

2021. 7. 7. · Jaw crushers are mainly used in rock and stone quarries, sand and gravel, mining, construction and demolition recycling, construction aggregates, material grinding in various applications. The flywheel, knuckle plates, pitman, camshaft and drive motor of the jaw crusher create the crushing action and provide the energy required to crush the material.

Learn Morehow a jaw crusher works and what it is used for

A Jaw Crusher reduces large size rocks or ore by placing the rock into compression. A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate. The space at the bottom of the "V" aligned jaw plates is the crusher product size gap, or the

Learn MoreJaw Crushers | McLanahan

Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and sometimes secondary size reduction. Applications Aggregates C&D Recycling Concrete Crushing Frac Sand Mining Jump To: How Jaw Crushers Work Resources Why McLanahan FAQs Features & Benefits

Learn MoreJaw Crusher | manufactor | thyssenkrupp Mining Technologies

Jaw crushers are used within the aggregates, cement, and mining industry, as they have been proven to be an efficient primary crusher for hard rock materials such as granite and others. The mining and cement industry also profit off their optimized crushing chamber. thyssenkrupp Mining Technologies jaw crusher types

Learn MoreJaw Crusher VS Cone Crusher | Advantages and Disadvantages

Jaw crusher adopts the extrusion process between the moving jaw plate and the static jaw plate. Application Field Cone crusher and jaw crusher are widely used, but the applicability of the two types of crusher is different. Jaw crusher has the most extensive adaptability and can meet the crushing requirements of almost any kind of materials.

Learn MoreIn- depth – Components of a Jaw Crusher | PROPEL INDUSTRIES

2021. 6. 14. · 3. Jaw Plate. The inward facing side of the jaw crusher pitman is covered with a jaw plate made of manganese which is an extremely hard metal. The jaw plates are usually symmetrical from top to bottom and can be used on either side. This comes handy as the wear occurs at the bottom (closed side) of the jaw and flipping them over provides another equal

Learn MoreHow Does a Jaw Crusher Work | Jaw Crusher | Kemper Equipment

All jaw crushers reduce large sized rocks, ore, or other material by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, "swing" jaw exerts force on the feed material by pushing it against the stationary plate.

Learn MoreWhy You Should Buy Directly From Jaw Crusher Manufacturers?

Jaw crusher manufacturers understand the importance of good customer service. That is why they hire knowledgeable and skilled employees to work in their customer service department. You will get the best service for crusher machines from the manufacturer. The manufacturer can even answer your questions before you purchase their jaw crusher.

Learn MoreJaw Crusher vs Cone Crusher: A Comparison - Sepro Aggregates

Jaw Crusher Benefits. Every site has different needs and requirements, so jaw crushers can be found in different sizes and capacities. This gives you the opportunity to make the most optimal choice for your project. If you are not sure what size fits your current needs, speak to one of our aggregate experts. Parts are easy to find, and maintenance is straightforward.

Learn More

Leave A Reply