Common Faults and Solutions of Cone Crusher

Replace the oil pan and thrust plate. 2. Oil temperature and oil pressure rise. The oil pressure in the thin oil lubrication system of the cone crusher increases and the oil return temperature also rises accordingly. The reason. The oil pipe or the oil groove in the crusher parts is blocked, and the safety valve fails.

Learn MoreCone Crusher Cavity Types And - Qiming Machinery

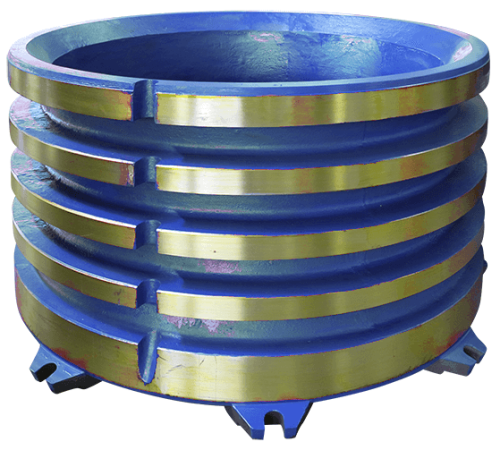

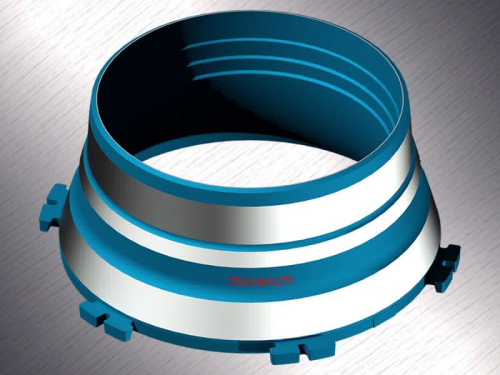

The most important factor in Cone Crusher liner selection is the feed. Cone Crusher Cavity Types. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as: 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two.

Learn MoreCone Crusher - Nesans Mining and Automation Private Limited

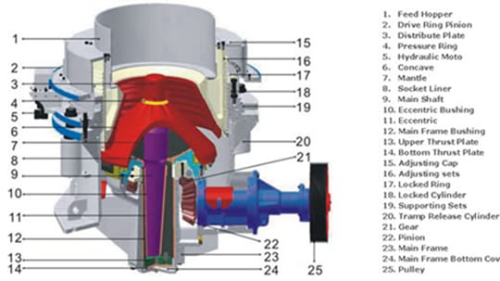

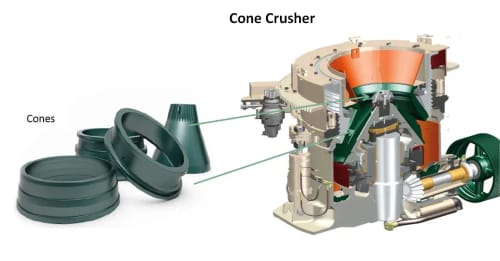

What is a Cone Crusher ? Cone Crushers are compression type of crushers used predominantly for the secondary and tertiary crushing purposes. Known for their

Learn MoreJaw Crusher vs Cone Crusher: A Comparison - Sepro Aggregates

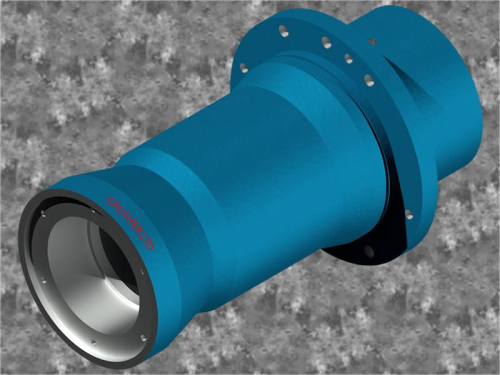

Cone crushers take care of secondary and tertiary crushing applications. Fine and medium-sized aggregates (used in asphalt and concrete, for example) are created by an eccentrically rotating shaft that grinds the rocks between a robust metal cone and a fixed wall. The Blackhawk 100 Cone Crusher is an example of a powerful cone crushing machine.

Learn MoreCone Crusher vs. Impact Crusher | Quarrying & Aggregates

The compression crusher (cone crusher) generally has lower maintenance costs due to less wear. As the replacement of spare parts is reduced, the equipment will reduce downtime. Effectively saving overhauling period and reducing overhauling quantities.

Learn MoreWhat is a Cone Crusher? - Definition from Trenchlesspedia

12/9 · The cone crusher, introduced by the brothers of Milwaukee in the 1920s, is a durable and simple solution that has made its mark. The technology continues to develop, and

Learn MoreCone Crushers | McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a

Learn MoreGet Latest Stationary Cone Crushers Market Research Study by HTF MI

Curious to know about market share of key-players or Sales volumes or revenues of Stationary Cone Crushers Market further segmented by type, application and important regions.: HTF MI brings you in-depth Industry analysis, facts & figures to complete Business strategy. Reach HTF now

Learn MoreCone Crusher - an overview | ScienceDirect Topics

These crushers are designed so that the head-to-depth ratio is larger than the standard gyratory crusher and the cone angles are much flatter and the slope of the mantle and the concaves are

Learn More12 tips to maximize cone crusher productivity - Outotec

2/11 · Avoid trickle feeding the crusher. Try not to trickle feed a cone crusher. In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher. A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to

Learn MoreCone Crusher - Mineral Processing & Metallurgy

4/19 · The cone crusher is usually set to give a 3/8-in. or ½-in. product when discharging to ball mills. Table 9 gives particulars of the different sizes of crushers. The capacity figures are based on material weighing 100 lb. per cubic foot and must be

Learn MoreWhat is a Cone Crusher| Advantages, Types, Parts and Specifications

The cone crusher is mainly used for secondary crushing and tertiary crushing in aggregate crushing of mines and quarries. Because of its strong crushing capacity and large output, it is more used for the crushing of medium-hard materials. The cutting-edge crusher technology has higher crushing efficiency and more convenient operation.

Learn MoreWhat Is a Cone Crusher and What Can It Do for You?

4/24 · Apr 24, . A cone crusher is one of many different types of crushers, like impact crushers, jaw crushers, and hammermills, that is used to process and reduce material like

Learn MoreCone Crushers - SolidsWiki

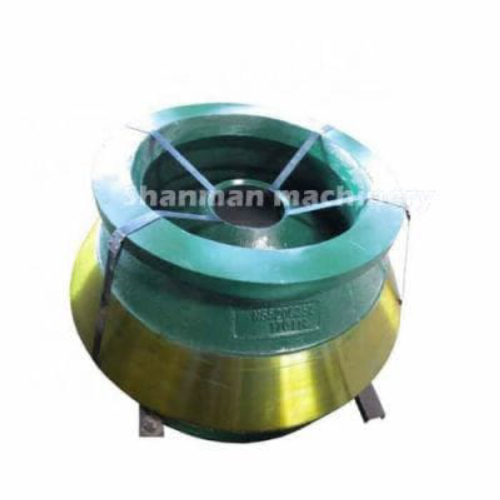

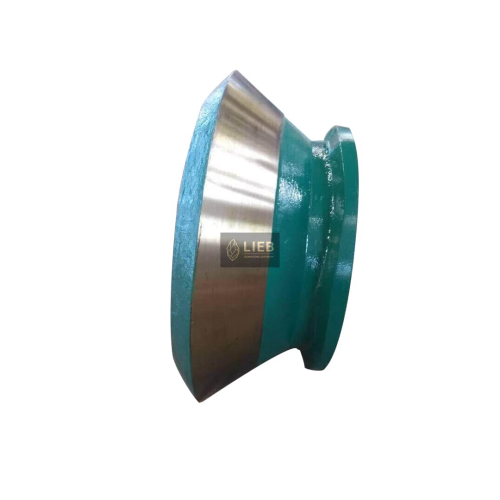

A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear resistant mantle, and the

Learn MoreWhat is a Cone Crusher| Advantages, Types, Parts and

Cone Crusher Advantages. Laminated crushing, high crushing efficiency, good shape of the discharged material. Medium and fine crushing cavity type, easy to switch, multi-purpose in

Learn MoreOur Range of Trio® Cone Crushers | Weir

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.

Learn MoreThe pros and cons of cone crusher applications - Quarry

4/16 · A cone crusher in a secondary crushing application will typically work with a 3.5:1 to 5:1 reduction ratio. Tertiary cone crusher configurations typically work with a reduction ratio of 2.5:1 to 4:1. The reduction ratio is defined as the ratio of the feed size for which 80 per cent will pass (F80), divided by the product size for which 80 per cent will pass (P80).

Learn MoreA Detailed Overview of Cone Crushers and What You Need to Know

A cone crusher has two sides: an open side and a closed side. As the material crushes, the particles that are small enough to fit through the open side fall through the space between the mantle and the concave. As the mantle gyrates, it creates a narrow point and a wide point.

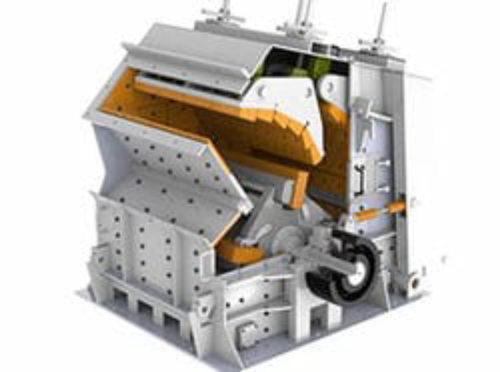

Learn MoreThe Differences Between Cone Crusher and Impact Crusher

Impact crusher uses the principle of impact crushing During operation, driven by the motor, the rotor rotates at a high speed. When the material enters the blow hammer effect area, it collides with the blow hammer on the rotor and breaks, and then is thrown to the counterattack equipment to be broken again, and then bounces back from the counterattack liner.

Learn MoreCone Crusher Applications - Blue Group

You will usually find cone crushers in a number of industries that revolve around mining, quarrying, and recycling. By means of attrition, the Cone Crusher

Learn MoreCone crushers - for demanding crushing needs - Outotec

Cone crushers are popular rock crushing machines in aggregates production, mining operations, and recycling applications. They are normally used in secondary, tertiary, and quaternary crushing stages.

Learn MoreWhat is a Cone Crusher?

Cone crushers are a type of compression crusher used by aggregate, coal, concrete, crushing, fracking sand, and mining industries, which reduces material by squeezing or compressing it until it breaks. Specifically, the material is compressed between an eccentrically rotating piece of steel, the mantle, and a stationary piece of steel, the bowl.

Learn MoreSelecting crushing chambers for cone crusher - Outotec

4/7 · This is discussed in more detail in the 12 tips to maximize cone crusher productivity blog post. Summarizing, larger setting → product size increases, capacity increases, power draw decreases. Example: The HP crusher chamber selection table shows the minimum opening settings. However, the presented settings are provided as a guide only.

Learn MoreA Detailed Overview of Cone Crushers and What You Need to

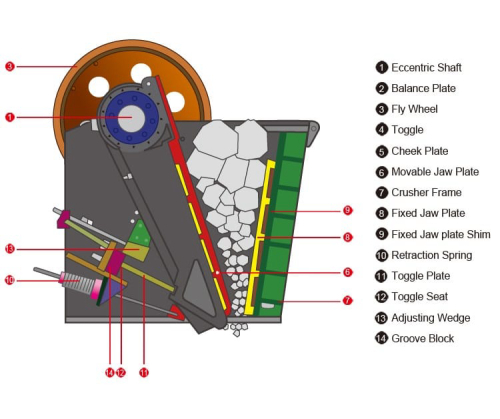

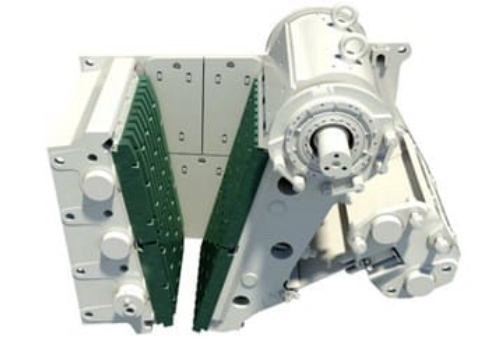

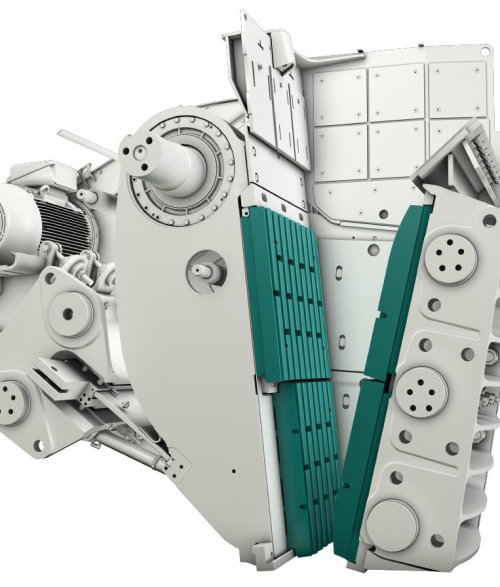

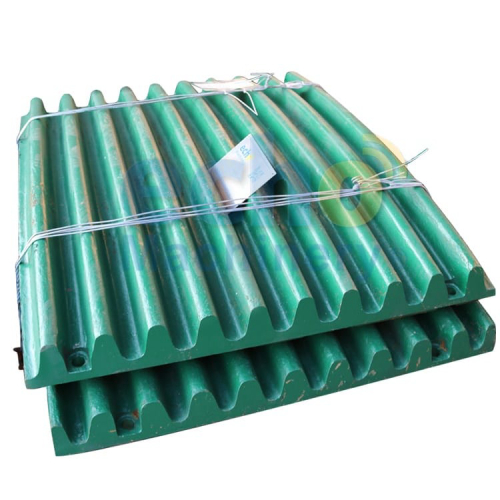

Jaw crushers are a compression crusher that uses a set of jaws to crush aggregate materials. This machine features a fixed jaw and a moving jaw,

Learn MoreWhat is the crushing capacity of the cone crusher?

The crushing capacity of a cone crusher refers to the amount of material crushed per unit time, usually in tons/hour. 1. The hardness of the material. The harder the material, the more difficult it is to break, and the more severe the wear of the equipment. The crushing speed is very slow, and of course the crushing ability is also very small.

Learn MoreWhat Is A Hydraulic Cone Crusher? - Machinery

The single-cylinder hydraulic cone crusher has a new crusher structure, optimized laminated crushing cavity type, and a fully intelligent automation control system. In general, it can be widely used in medium crushing, fine crushing, and ultra-fine crushing operations. The working site of the cone crusher in India.

Learn MoreCone Crusher Basics - Porter Group

INSIDE YOUR CONE CRUSHER. The basic principle is straightforward: the material to be crushed (the feed), drops into the crushing chamber. The mantle is a moving part that gyrates in an eccentric motion. That is, it does not remain completely centred – it swings slightly as it rotates, continually altering the gap between the mantle and the

Learn MoreCrusher - Wikipedia

A cone crusher is suitable for crushing a variety of mid-hard and above mid-hard ores and rocks. It has the advantage of reliable construction, high productivity, better granularity and shape of finished products, easy adjustment and lower operational costs.

Learn MoreCone Crushers | Mobile & High Productivity | Finlay

The Finlay® C-1554 tracked cone crusher is the ultimate mobile solution for any aggregates producer or contractor looking for a high productivity machine that

Learn MoreHP Series™ cone crushers - Outotec

Cone crushers Features ® HP Series™ cone crushers are reliable rock crushing machines for all demanding quarrying, mining, and tunneling applications. Over the years they have become the most popular modern cone crushers in the world with over 10,000 machines sold globally. Optimized performance

Learn MoreCone Crushers - MEKA Crushing & Screening Plants

Cone crushers have been used as primary, secondary and tertiary crushers for quite a long time. They are widely employed for crushing hard and abrasive

Learn More

Leave A Reply