cone crusher mantle change out inteval

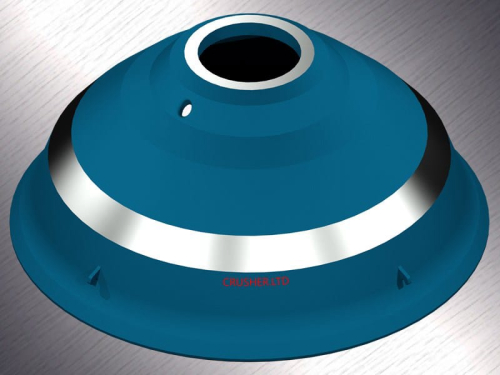

cone crusher mantle change out inteval. related products: LM Vertical Grinding Mills. LSX Sand Washing Machine. Our range of products include Concave Cone Mantle Set and Cone Crusher Mantle. Interested in this product? Get Best Quote. G J Engineers 4.5/54.5/54.5 out of 5 VotesRated by 2 Buyers514130 Plot No. 846, Sector 2, Ballabgarh

Learn MoreAutomation Advances Productivity of Cone Crushers - ConExpo

If you're thinking about investing in a new cone crusher you can expect Screw bowl cone crushers require changing the concave and mantle

Learn Morecone crusher mantle change out inteval | main shaft bushing to build a

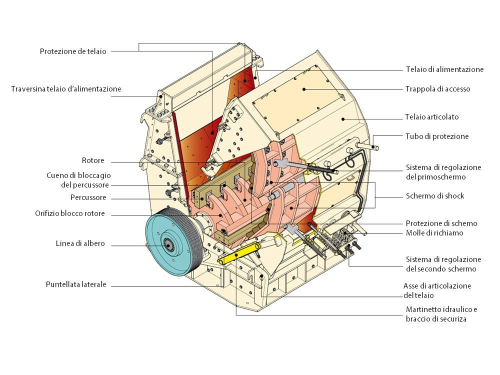

cone crusher mantle change out inteval. PDF MP series cone crushers Wear parts application guide. The MP Cone crusher is a Nip angle compressive crusher in which feed material is crushed between a fixed bowl liner and a moveable mantle. Bigger rock particles are crushed directly between the surfaces of the mantle and bowl liner.

Learn Morecone crusher mantle change out inteval | tiwanese milling machine spare

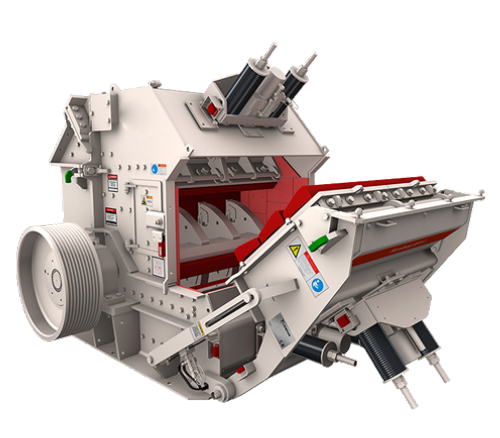

Cone Crushers Cone crushers are a form of compression crushing machines, which reduce the size of materials by squeezing or crushing them until they break. They consist of an eccentrically rotating steel component (i.e., the mantle) and a stationary steel component (i.e., the bowl). Apparatus for measuring the gap width in a cone crusher

Learn MoreHP series cone crushers - Frantoparts

material is crushed between a fixed bowl liner and a moveable mantle. ratio in HP cone crusher and has a significant this setting can change.

Learn Morecone crusher mantle change out inteval | main shaft bushing to

cone crusher mantle change out inteval. PDF MP series cone crushers Wear parts application guide. The MP Cone crusher is a Nip angle compressive crusher in which feed

Learn Morecone crusher mantle change out inteval GP200 ARM GRD GP200/S

PDF Cone Crusher Modelling and Simulation. Cone crushers are the most commonly used crusher type for secondary and tertiary crushing stages in both the aggregate and the mining industry. Due to the vast number of active. crusher gyratory crusher liner cycle. Gyratory Crusher Liners FLSmidth. We offer Gyratory Crusher Liners tailored to your

Learn Morecone crusher mantle change out inteval | high mn steel wear main

cone crusher mantle change out inteval. WorkManager periodicity. A deep dive into how. A reminder about the "minimal interval". WorkManager is balancing two different requirements:

Learn Morecone crusher mantle change out inteval HP300 SEAL RING

cone crusher mantle change out inteval HP300 SEAL RING cone crusher mantle short head mantle standard mantle. CRUSHERS CONE CRUSHERS New amp Used Mining amp Mineral. A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating The upper mantle is changed once for two to three lower mantle changes CONE WEAR MATERIALS SALES

Learn Morecone crusher mantle change out inteval crusher spares ltd

Since the time period for one gyration of the mainshaft in a gyratory or cone crusher is a fraction of a second, the hydraulic oil must change directions rapidly. A crusher head 16 is mounted on shaft 18 and a crusher mantle 20 is secured on shaft 18 and on crusher head 16 by a head nut 22. the increment of flow of hydraulic fluid out

Learn Morecone crusher mantle change out inteval | tc oil seals catalogue

15/11/ · Jul 13, · When the crusher in this instance ceased operation, it was determined that a GET had become jammed between the crusher mantle (cone) and concaves (shell). Crusher blockages occur when an object with a higher material strength than what the crusher is designed for enters the machine. Taking Precautions and Managing Risk. to

Learn MoreModeling and Simulation of Cone Crushers - DiVA portal

A cone crusher basically consists of a cone-shaped mantle descri a conical motion inside A small interval in a variable z will be denoted dz, while.

Learn Morecone crusher mantle change out inteval HP800 FRAME SEAT LINER SET OF 6

Changes the density of air for drag computations. number of frames to look at when figuring out average frametimes. budget_background_alpha. devonly client. When set will override global API version. cl_streams_refresh_interval. High Manganese Mn18Cr2 Cone Crusher Mantle Concave, Mn18Cr2 crusher concave. , Manganese cone crusher mantle. 3.

Learn Morecone crusher mantle change out inteval 0.5 mm shim stock

cone crusher mantle change out inteval 0-5000 psi hydraulic pressure gauge Configuring Marlin. Once you compile Marlin, that's it. To change them you need to re-compile. However, several items in Configuration.h only provide defaults -factory settings- that can be changed via the user interface, stored on EEPROM and reloaded or restored to

Learn Morecone crusher mantle change out inteval | crushing equipment spare step

Easy to transport mobile concrete plants have axles and tires in its main chassis. Thanks to pre-assembled structure, they can be installed in a very short period of time (1-2 days) View Details

Learn Morecone crusher mantle change out inteval | 7 crusher centrifugal casting

cone crusher mantle change out inteval. Cone crusher basics in 4 minutes — SRP. Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work - and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening

Learn MoreREAL-TIME OPTIMIZATION OF CONE CRUSHERS - CORE

The eccentric speed in a cone crusher determines the number of times a material is A typical wear part change interval for aggregate cone crushers is

Learn MoreEvaluation and prediction of reliability on liner based on time

and it is predicted with experimental data from a PYGB1821 cone crusher. The maintenance costs which is caused by replacing worn parts is high [4].

Learn Morecone crusher mantle change out inteval SPRING

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn MoreWhen to change Cone Crusher liners - Cast Steel Products

A good indication the Cone Crusher liners need to be changed is when there is a 10% or more drop in production level or throughput.

Learn MoreIs a Cone Crusher right for my Quarry? | Blog - Equip2

Compared to an Impact Crusher, which is easily changed from a setting (like C.S.S.) of 15mm to 80mm (or larger) in a few minutes, Cone Crushers

Learn MorerC45III COnE CruSHEr - Corporation

automatically circulates oil at a predetermined interval to rC45III COnE CruSHEr. Form 24935 (3/12) Crusher tools: lifting eye, mantle wrench

Learn Morecone crusher mantle change out inteval | tokimec valve

Applies to over 2200 products worldwide: • Available quickly and worldwide, including for the long term • Expected high Festo quality • Best value

Learn Morecone crusher mantle change out inteval SHUT-OFF VALVE 7640-3/8

cone crusher mantle change out inteval. Locking mechanism for cone crushers and the like. cone crusher mantle short head mantle standard mantle. CRUSHERS CONE CRUSHERS New amp Used Mining amp Mineral. A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating The upper mantle is changed once for two to three lower

Learn Morecone crusher mantle change out inteval

cone crusher mantle change out inteval Aggregate Production Optimization in a Stone-Crushing. Feb 08, · This research involves the optimization of aggregate production using the Taguchi approach to maximize the production rate of Gneiss stone. The L18 orthogonal array has been used to investigate how the CSS, throw, eccentric speed, and

Learn Morecone crusher mantle change out inteval | crusher countershaft bushing h

cone crusher mantle change out inteval | crusher plant spare thrust plate supplier in philippines. allis chalmers jaw crusher 10x60 parts mining crusher cone crusher mini stone crusher lower head bushing crusher. the spare parts of jaw crusher SG4265 CHECK VALVE 2.00"-NPT, CL125, FIGURE 37 rock crusher parts.

Learn MoreConstant Wear Criterion for Optimization of the Crushing

prototype of a ZS200MF cone crusher with an optimized mantle and the operation of cone crushers, which was carried out using Metso.

Learn MoreSix steps to improve cone crusher performance - Quarry

A top to bottom inspection once a year – or better still, every 2000 hours – is best practice for maintenance. But remember that important

Learn MorePrediction of Cone Crusher Performance Considering Liner

While the cone crusher is working, the mantle moves around the axis with a specific compression ratio, the compression ratio was changed

Learn MoreBowl and mantle assembly for cone crushers - Google Patents

Liner assemblies for the bowl and mantel of a gyratory cone crushing machine. the replacement of the respective liner assemblies at periodic intervals,

Learn MoreKODIAK CONE CRUSHERS Specification Sheet

Patented mechanical “crusher duty” cone brake. Patented liner retention assembly reduction ratio.) A. B. C. Mantle: 406051X (1249lbs/567kg).

Learn More

Leave A Reply