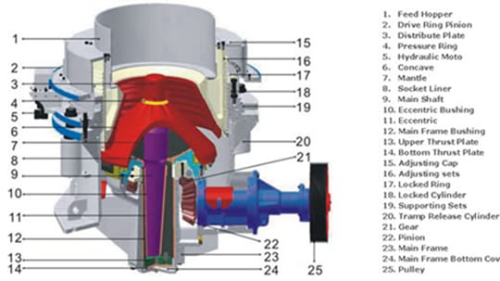

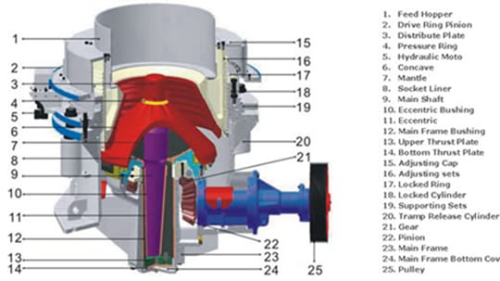

Cone Crusher | Working Principle | Animation

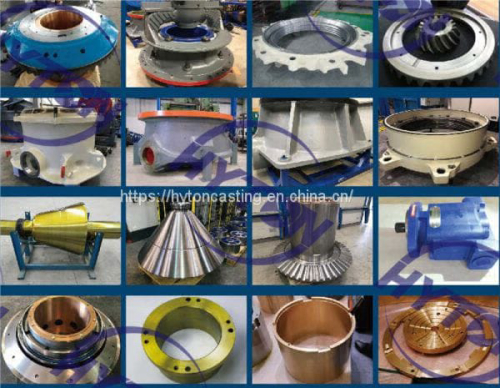

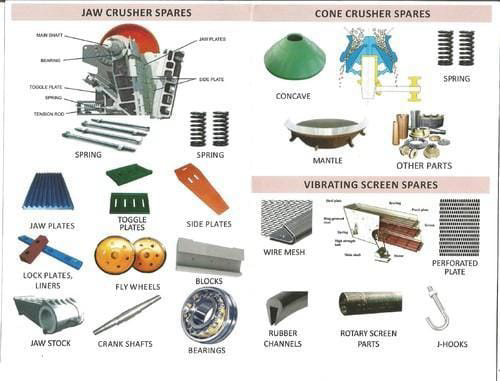

8/15 · Cone crusher parts It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the

Learn MoreCone crusher bowl Manufacturers & Suppliers, China cone crusher bowl

cone crusher bowl manufacturer/supplier, China cone crusher bowl manufacturer & factory list, find qualified Chinese cone crusher bowl manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com. For Buyer Search Products

Learn MorePatriot® Cone Crusher - Superior Industries

Bushing cones, like Superior's Patriot Cone Crusher, consist of a rotating mantle inside a steel bowl. As rock is compressed between the mantle and the bowl

Learn More12 tips to maximize cone crusher productivity - Outotec

2/11 · A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to have a proper “loaded bearing alignment”. An optimal power range is to operate between 75%-95%. Operating a crusher above 110% rated power can cause premature crusher failure.

Learn MoreBowl Rotation Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Conical crusher anti-spin assembly - Crusher patent 20030102394 The Bremer device utilizes a resetting torque limiter that permits rotation of the crusher head in the 62 permits rotation of the head 30 with the bowl 42 once PSM Crusher - Gyratory crusher with automatic control system

Learn MoreBowl And Mantle For Cone Crusher - Alibaba

Create fine powders for industrial projects with crusher machines. Browse the bowl and mantle for cone crusher range on for all types at

Learn MoreCone Crusher Bowl - Factory, Suppliers, Manufacturers from China

Cone crusher bowl liner GP550 suitable for common crusher HPC160, HPC220, HPC315, HPC400 concave bowl liner for cone crusher Cone crusher bowl liner GP300S suitable for

Learn MoreLocking mechanism for cone crushers and the like - Google

B02C2/04 Crushing or disintegrating by gyratory or cone crushers Another object is to provide a releasable upthrust to the bowl of a cone crusher.

Learn MoreCone Crusher Bowl Mill Crusher Animation | Crusher Mills, Cone Crusher

bowl mill crusher animation - Crushers, Raymond Mill Similar to the vertical roller mill, it also uses tires to crush coal. There are two types, a deep bowl mill, and a shallow bowl mill. vertical roller mill animation.

Learn MoreCone Crusher Liners|Concave Bowl And Mantle Liner

Practices in mine crushing and aggregates production industry have proven that performances of our liners are similar to, or even beyond that of original cone crusher manufactures. Reasons For Choosing Our Concaves and Mantles. Design of cone crusher liners depends on users' actual needs.

Learn More12 tips to maximize cone crusher productivity

2/11 · A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to have a proper “loaded bearing alignment”. An

Learn MoreCone Crusher Bowl Liner, N55208141 - Pinterest

Qiming Machinery manufactures the aftermarket cone crusher bowl liner (Part number: N55208141, Weight: 537kg )for the customer who uses HP300 cone

Learn MoreHP4™ cone crusher - Outotec

HP4™ cone crusher is designed with safety, simplicity and eco-efficiency in mind. It is a robust rock crushing machine used especially in secondary, tertiary, and quaternary crushing stages in aggregates production and mining applications. HP4™ is part of the latest generation of cone crushers with improvements such as automatic

Learn MoreSnow Cone Machine & Supplies - The Party Pros

Snow Cone, Syrup Strawberry at $12.00 * Prices are subject to change. * Please call us with any questions about our snow cone machine supplies in Hillsboro OR and the Portland Metro area. Connect with us; THE PARTY PROS: 5604 NE Clara Ln, Hillsboro, OR 97124; Phone: (503) 844-9798;

Learn MoreCone Crusher Bowl Liner - Victor Bray

10/3 · The cone crusher bowl liner is attached at the top of the main shaft. The bowling line fits on the top of the mantle which is also situated at the top of the main shaft. When both the

Learn MoreCone crusher liners High-quality bowls and mantles

Austenitic Manganese Steel is the industry standard material for cone crusher liners. Due to its ability to work-harden during operation, it has proven to be

Learn MoreThe pros and cons of cone crusher applications - Quarry

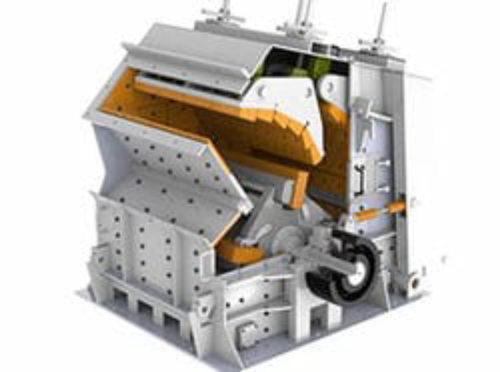

4/16 · Cone crushers can be categorised into three main design types. With floating bowl and screw bowl cone crushers the upper frame raises to open CSS or relieve crushing pressure. The third type – the spider-bearing cone crushers – incorporate a shaft supported by a hydraulic piston which controls CSS and crushing pressure.

Learn MoreCone Crusher - Mineral Processing & Metallurgy

4/19 · Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble (critical size) build-up problem. Normally, heavy-duty short

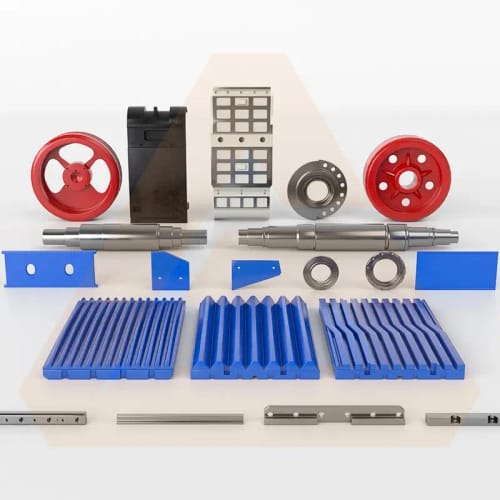

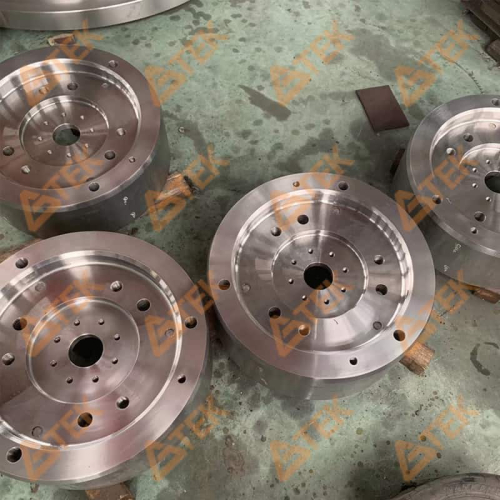

Learn MoreBowl Liner & Mantle | Wear Resistant Crusher Parts - GTEK

And the bowl liner which is also known as cone crusher concave, is the sacrificial wear liner which sets inside the upper frame for protecting the upper

Learn MoreCone Crusher Explained - saVRee

Cone Crushers Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher. Cone crushers are more often used for 2nd, 3rd & 4th stage crushing steps (although not always).

Learn MoreCone Crusher Parts - 911 Metallurgist

Bowl. This part, which is screwed into the adjustment ring, is the means of setting of the machine. Adjustment is performed by rotating the bowl

Learn MoreCone Crusher Liners: How to Select and When to Change

The crushing chamber in a Cone Crusher is the space created between the the seat on the support bowl or the head of the Cone Crusher.

Learn MoreCone Crusher | Working Principle | Animation | Engineering Intro

Cone crusher parts It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper. Rocks get squeezed at the same moment when it enters in between the bowl liner and mantle. Only one time breaking is carryout of larger pieces of rocks from ore.

Learn MoreWedge, HEC, Bowl Liner and KMD 1750 Cone Crusher

Wedge, HEC, Bowl Liner and KMD 1750 Cone Crusher · Availability: 10 · Mfg: HEC · SKU: GSM043-0621-01-02181 · Location: Rajasthan, India.

Learn MoreMild Steel Cone Crusher Bowl Liner - IndiaMART

Holo Industries Private Limited - Offering Mild Steel Cone Crusher Bowl Liner at Rs 90/kilogram in Kolkata, West Bengal. Read about company.

Learn MoreTrio® TC Series Cone Crushers - The Weir Group

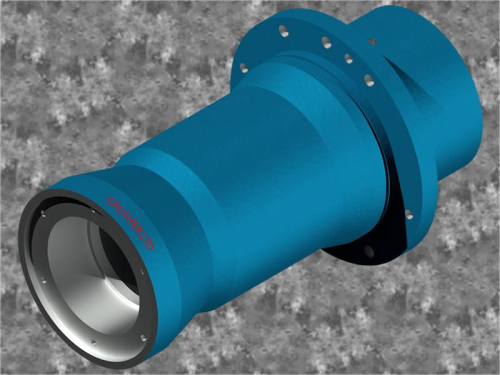

The Trio® TC Series live-shaft cone crusher is designed for secondary, alloy steel castings and welded mainframe liners; Hydraulic bowl adjustment

Learn MoreCone Crusher Parts

2ft 1959-2997 bowl liner bolt ® 2ft 2005-1176 bowl ® 2ft 2005-1401 bowl ® 2ft 2206-6641 inner eccentric bushing ® 2ft 2281-4030 adjustment cap ® 2ft 2302-1101 main frame cap ® 2ft 2618-0961 feed cone ® 2ft 3113-7351 eccentric ® 2ft 3378-1436 mainframe ® 2ft

Learn MoreUS6981665B2 - Cone crusher bowl adjustment mechanism - Google

A conventional crusher, such as, an HP700™ conical rock crusher manufactured by Minerals of Milwaukee, Wis. includes a bowl threaded to an adjustment ring which is fixed to the main frame by

Learn MoreCone Crusher - an overview | ScienceDirect Topics

Cone crushers were originally designed and developed by around 1920 and therefore are often described as cone crushers. As the mechanisms of crushing in these crushers

Learn MoreCone Crusher Bowl Liner

The Cone Crushers consist of a bowl liner, a mantle, both main shaft and frame, compression, and an eccentric inner and outer bearing. The cone crusher plays an

Learn MoreDismantling cone crusher - Wear Parts For Industry | Qiming Casting

Cone crusher work as a very crucial role in the whole crushing production line, directly influences the whole crushing process. When repair the equipment must be move concave, mantle, eccentric bushings, and other components throughout the entire dismantling, so we can understand the specific damage, targeted for repair.

Learn More

Leave A Reply