Characteristics and Comparison of Four Types of Jaw Crushers

Sometimes single toggle jaw crusher performs better than double toggle jaw crusher in productivity. Get Latest Price Dodge jaw crusher In the dodge type jaw crushers, the jaws are farther apart at the top than at the bottom which form a tapered chute so that the material is crushed progressively smaller and smaller as it travels downward until

Learn MoreJaw Crusher Working Principle – StudiousGuy

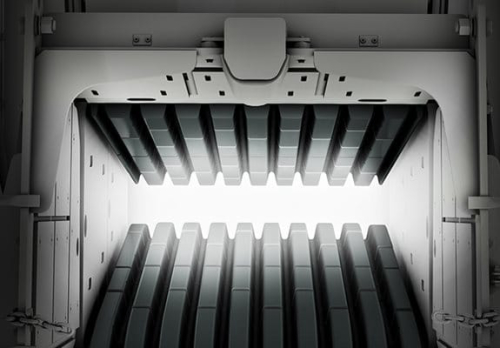

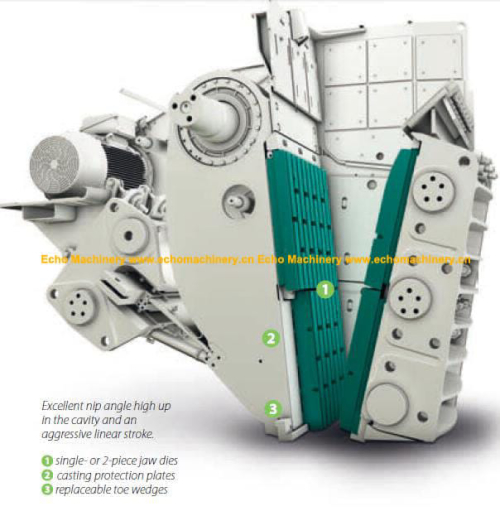

A double toggle jaw crusher consists of two shafts and two toggle plates. The first shaft is the pivoting shaft on the top of the crusher, whereas the other shaft is the eccentric shaft that is used to drive both the toggle plates. Advantages of a Jaw Crusher. 1.

Learn MoreDouble Toggle Jaw Crusher VS Single Toggle Jaw Crusher

19/10/ · Commonly used jaw crushers include double toggle jaw crushers and single toggle jaw crushers. When the double toggle jaw crusher is working, the movable jaw only makes a

Learn MoreJaw Stone Crusher | Single Toggle vs Double Toggle - JXSC Mine

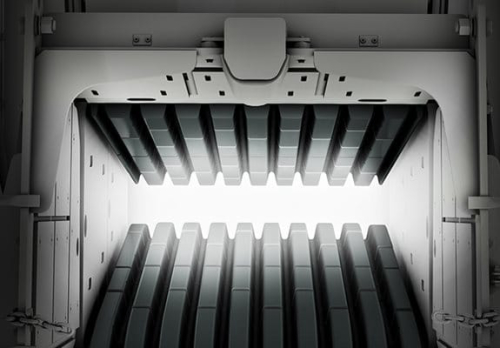

The upper arc is small, the lower arc is large, and the crushing efficiency is low. The fragmentation ratio is generally 3-6. Because the movement track is simply so-called a single toggle jaw crusher. The structure of the single – toggle jaw crusher is compact and simple, and the force of transmission parts such as eccentric shaft is small.

Learn MoreKue-Ken Jaw Crushers - Crushing and Screening Plant

Kue-Ken Jaw Crusher Advantages:. Our Kue-Ken Jaw Crushers have a double toggle action to give the maximum mechanical advantage to the eccentric. Crushing on the downward stroke enables a much lighter pitman and toggles to be employed, so reducing inertia and ena higher operating speeds and greater throughput to be achieved.

Learn MoreSingel Toggle Jaw Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

aggregate jaw crusher,china jaw crusher,rock crushers,single Single Toggle Jaw Crusher: The series of jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even.

Learn MoreHow does a Single Toggle Jaw Crusher work? | RUBBLE

Single toggle jaw crushers take the brunt in combination with other crushers and screens. Crusher trains are a combination of several mobile crushing and screening plants to achieve a

Learn MoreSingle Toggle Jaw Crushers - TDX

Jaques Single Toggle. Jaw Crushers are designed for exceptionally heavy and continuous crushing applications. Well suited for mobile mounting, these rugged.

Learn MoreShcrusher Toggle Plate Jaw Crusher

PIONEER Jaw Crusher 2036 for was positioning a wedge bar to secure the upper liner plate in a stationary jaw crusher 2036 Jaw Crusher Single-Toggle, Jaw Crusher - Machinery Jaw Crusher has the features of high toggle plate, toggle backseat, adjusting screw, returning spring, fixed jaw plate and moving jaw plate.

Learn MoreSingle Toggle vs Double Toggle Jaw Crusher - JXSC Machine

The double toggle jaw crusher has two forms of working direction: one is a swing motion toward the fixed die plate, and the other is a vertical

Learn MoreJaw Crushers– - TerraSource Global

Additionally, our double toggle jaw crushers do not require massive and costly foundations as do other jaw crusher designs. That's because our jaws are designed

Learn MoreSingle Toggle Jaw Crusher - MODERATE MACHINES

Powered by AC motor, this single toggle jaw crusher has extensive applications in construction and mining arena where it is used for uniform crushing of iron ore, quartz, copper ore and marble to name a few. This primary crusher is equipped with crushing chamber with dead angle free design so that its feeding capacity can be raised. Known for

Learn MoreSingle Toggle Jaw Crushers - Rullitech Engineers

Sr. No Name of Equipment Size & Type Qty Place Year 1 Single Toggle Jaw Crusher 12 x 7 01 No Nagpur 24/2/1986 2 Single Toggle Jaw Crusher 12 x 7 01 No VAPI 17/3/1990 3 Single Toggle Jaw Crusher 20 x 12 01 No Ambav 21/10/1991

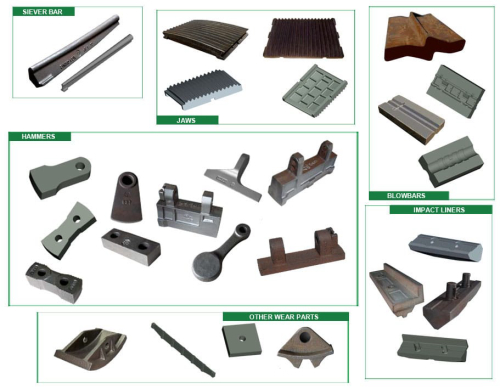

Learn Moredouble toggle jaw crusher pdf wearing parts of crusher

Jaw Crushers Our range of products include single toggle jaw crushers, double toggle jaw crushers, 36x24 jaw crusher, 30x24 jaw crusher, 24x16 jaw crusher and 30x20 jaw crusher. PDF Chapter 1 1.0 Introduction. Fig 2.5: working principle of a jaw crusher 2.1.2 TYPES OF JAW CRUSHERS Typically there are two types of jaw crushers. i.

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

In single-toggle jaw crushers, the movable jaw is supported by the bearing on an eccentric shaft driven by the pitman to which it is attached. The pitman is supported by a toggle plate at the bottom of the moveable jaw. Toggle plate compressed between moveable jaw and main body. This mechanism ensures that any point on the moving jaw moves in

Learn MoreDouble Toggle Jaw Crusher

Contains big roller bearing in two sides · Large jet entrance for making easy to crush the input material in crushing chamber · Connected tab plates to swing jaw

Learn MoreAnalysis of the Single Toggle Jaw Crusher Force ... - Hindawi

This paper sets out to perform a static force analysis of the single toggle jaw crusher mechanism and to obtain the force transmission characteristics of

Learn MoreAnalysis of the Single Toggle Jaw Crusher Force Transmission ... - Hindawi

The single toggle jaw crusher mechanism can be modelled as a planar mechanism, as shown in Figure 1. However, in this mechanism, it is the coupler that is the output link and the transmission angle, as defined in the above cited literature, fails to be a suitable indicator of the efficacy of force transmission. Therefore, a better indicator of

Learn MoreThe kinematics and mechanical advantage of the double

The purpose of this article is to obtain a comprehensive mathematical description of the kinematics of a double-toggle jaw crusher.

Learn Morejaw crusher toggle plate work | birdsboro crusher pin bush

The toggle plate of the jaw crusher was supposed to break when uncrushable material passed through the crusher The toggle plate did not break and did not act as a safety device The crew tried to dislodge the rock with a backhoe tooth cut from another piece of equipment and attached to a chain.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

20/07/2022 · For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large production. It is inevitable for crusher to get wear because of long-time crushing work, and all you can do is try your best to maximize its service life by regular check and timely maintenance.

Learn MoreJaw Crusher | manufactor | thyssenkrupp Mining Technologies

This system results in a higher capacity than that achieved with a double-toggle jaw crusher with the same feed opening. Available in various sizes, they achieve throughputs of 250 t/h to 1,400

Learn MoreSingle Toggle Jaw Crushers Manufacturer,Single Toggle Jaw

Double Toggle Jaw Crushers Warranty : 1 Years Feature : High Performance, High Efficiency Price : 3000000 INR Material : Galvanized Steel Product Type : Double Toggle Jaw Crushers Color :

Learn MoreJaw Rock Crusher Supplies By Trusted Manufacturer - AGICO

A double toggle jaw crusher has two shafts and two toggle plates. When it works, the moving jaw only involves arc swing motion. Single toggle jaw crusher. A single toggle jaw crusher has one shaft and one toggle plate. The eccentric shaft is on top of the moving jaw allowing the moving jaw to move in arc swing and up down at the same time.

Learn MoreStudy on Liner wear in Single Toggle Jaw Crushers - IJSER

Single toggle jaw crusher, one of the popular commi- nution machines used in mines and quarries, is faced with this problem of rapid abrasive wear of its jaw

Learn MoreSingle Toggle Jaw Crusher - Mechtech Engineers

With a robust build, and designed for versatile applications, MechTech Single Toggle Jaw crushers are capable of crushing soft to medium and very hard

Learn MoreHow does a Single Toggle Jaw Crusher work? | RUBBLE MASTER

Jaw crushers are used for a variety of natural stone materials: soft and hard stones, highly abrasive rock, ore, and for concrete recycling with lots of rebar. Easy maintenance & low wear Jaw ties and cheek plates last for a very long time and can be changed easily and quickly. A single toggle jaw crusher works like a giant nut cracker

Learn MoreJaw Crusher Toggle Plates vs. Hydraulic Toggle Relief Systems

10/04/ · Earlier in March, unveiled its own hydraulic toggle relief system at CONEXPO-CON/AGG , North America’s largest construction trade show. The hydraulic toggle relief system is available to be equipped onto any jaw crushers and will reduce unexpected downtime, decrease unnecessary replacement costs

Learn MoreCJ613 Single-Toggle Jaw Crusher With A Heavy Duty Design

CJ613 single-toggle jaw crusher is engineered for even the toughest applications thanks to its heavy-duty design. Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total cost . Email us Request a quote.

Learn MoreSingle Toggle Jaw Crusher - SBM Mineral Processing

SINGLE TOGGLE JAW CRUSHER. A wide range of single toggle jaw crushers STE with a processing capacity range of 2 t/h - 1,100 t/h from the smallest

Learn MoreMethod for adjustment of jaw crusher toggle block, and device

The objective of this invention is to provide a method to adjust the position of a jaw crusher toggle block, and a device used for said method;

Learn More

Leave A Reply