What Is Primary, Secondary, and Tertiary Crushing?

Primary crushing is the first stage of material reduction and can sometimes be the only stage needed to generate the desired product for a job. Depending on the setup, primary crushing will take the larger material that has been blasted, excavated, or reclaimed and process it through an impactor, jaw, or gyratory crusher to generate a range of

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining

thyssenkrupp gyratory crushers represent today’s state-of-the-art. They are designed for high performance and, at the same time, cost-effective operation, i.e. low servicing and

Learn MoreCompare Gyratory Crusher vs Jaw Crusher - Mineral Processing & Metallurgy

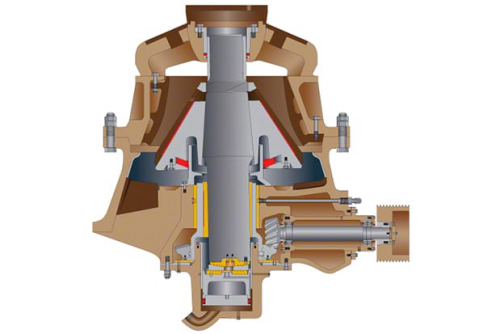

Primary crushing is the first of these stages. Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER. Although they don't look anything like they do have similarities that put them into the same class of crusher. Their CRUSHING SPEEDS are the same, 100 to 200 revolutions per minute.

Learn MoreGyratory Crusher Parts - Wear Parts For Industry | Qiming Casting

Furthermore, our premium range of primary gyratory crusher manganese steel and alloy castings are proven in mining and aggregate production applications worldwide. On the other hand, Qiming Casting’s engineers had researched new material for gyratory crusher mantle, which spans life can be 1.5-2 times than normal manganese mantle.

Learn MoreCG820 Primary Gyratory Crusher For Safe Crushing

Gyratory crusher. CG820i crusher is built to be robust, reliable and efficient. Connected to My , they revolutionize availability and optimize uptime by giving you actionable insights into how the crusher is performing. All to give you optimal reliability and drive down operating costs. Email us Request a quote.

Learn MorePrimary Crushing - Mineral Processing & Metallurgy

2/26 · The term “primary crusher,” by definition, might embrace any type and size of crushing machine. The term implies that at least two stages of crushing are involved, but in many cases the machine which performs the function of initial crusher is the only crusher in the plant. The factors influencing the selection of a crusher for this service

Learn MoreApplication guide SUPERIOR® primary gyratory crusher wear

Outotec’s primary gyratory crusher range includes 4 basic head sizes (65”, 75”, 89” and 110”), in addition to which the Super Spider upgrade provides two additional larger feed openings. The patented U-shaped spider arms reduce twisting during crush

Learn MoreHillsboro Clinics - Virginia Garcia Memorial Health Center

Hillsboro Primary Care Clinic. 226 SE 8th Ave. Hillsboro, OR 97123. Directions. Phone: (503) 601-7400. Mailing Address: PO Box 6149 Aloha, Or 97007. Clinic Hours. Monday 8:00 AM - 6:30 PM. Tuesday 8:00 AM - 6:30 PM. Wednesday 8:00 AM - 6:30 PM. Thursday 8:00 AM - 6:30 PM. Friday

Learn MoreCrusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn MoreCG850 Primary Gyratory Crusher With Large Feed Opening

CG830i crusher offer excellent reliability and safer & faster maintenance - up to 30% faster than competing crushers. A robustly designed one-piece main shaft and reinforced shells are made for tough use. The one-piece spherical spider bearing offers 5 times longer wear life than competing spider bushing design.

Learn MoreCG650 Primary gyratory crusher

Our CG650 primary gyratory crusher is a highly efficient and robust machine that is engineered to offer high performance, and stable and safe

Learn MoreGyratory Crushers - 911 Metallurgist

Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of

Learn MoreSuperior™ MKIII 60-89 primary gyratory crusher - Outotec

Superior™ MKIII 60-89 primary gyratory crusher provides increased throughput coming from increased speed and installed power that brings overall benefits to your primary crushing circuit. High throughput Reduced downtime Fast wear parts exchange Increased safety

Learn MoreTraylor 1000 TPH Primary Gyratory Crusher

1000 TPH Primary Gyratory Crushing Plant Item #1 – Fuller-Traylor Model 42-70 Type TCB Gyratory Crusher with cast steel two piece mainframe,

Learn Morereleases primary gyratory crushers - Australian Mining

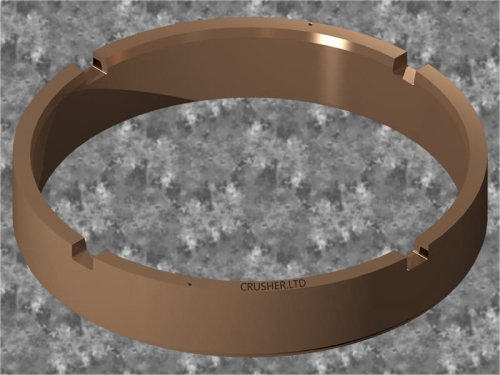

has released its re-designed 60-110E primary gyratory crusher. The new primary crusher features a reconfigured Spider, one piece bottomshell as well as a new rim liner retention system. The crusher also includes a 20% reduction in weight but with no the

Learn MoreGyratory crushers - thyssenkrupp

When it comes to crushing blasted hard rock in ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary crushing is second to

Learn Moreprimary gyratory crusher China Manufacture, Exporter, Supplier

primary gyratory crusher. To be able to ideal meet up with client's needs, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Cost, Fast Service" for primary gyratory crusher and continuously make improvements to service high-quality.

Learn MoreGyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Learn Moreprimary gyratory crusher parts | bottom shell bushing cedarapids cone

Feb 28, · A task group comprising Finland's and the US's best experts in wear parts materials and primary gyratory crusher technologies was set up. As a result of the engineering studies, proposed an optimized cavity, including a one-piece, 3.3m tall, 13-ton floating-type mantle, casted of ductile XT525 manganese steel and

Learn MoreSuperior™ MKIII Series primary gyratory crushers - Outotec

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Higher throughput Increased speed, installed power and mechanical improvements. Reduced downtime

Learn MorePrimary gyratory crusher parts - Outotec

Primary gyratory crusher spare parts. Outotec is the industry leader in manufacturing gyratory crushers with over sixty years of experience. As the popular crushers, our primary

Learn MoreGyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crushing chamber below.

Learn MoreTLC for Primary Crushers | E & MJ

TLC for Primary Crushers. Safety is paramount when working on such large, heavy pieces of equipment. (Photo: Outotec) A gyratory crusher is a significant investment for any mine. Take care of it and it will serve you well. Primary gyratory crushers are easily the hardest working piece of fixed plant on a mine site.

Learn MoreGyratory Crushers - SolidsWiki

Gyratory cone crushers can be used for primary or secondary crushing. The crushing action is caused by the closing of the gap between the mantle

Learn MorePrimary Gyratory Crusher Definition | Law Insider

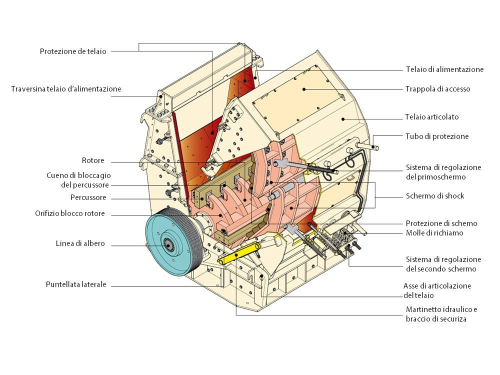

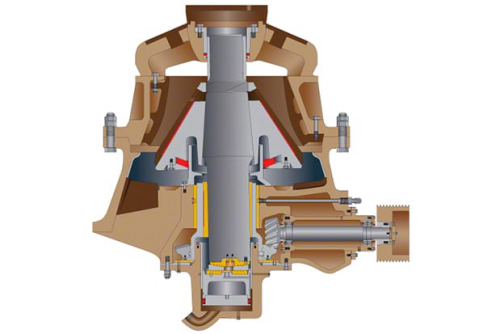

Primary Gyratory Crusher means a machine used as a primary crusher of rocks in mines, quarries, and certain other applications, that achieves crushing by using two cones (one placed inside the other) in which the interior mobile cone is inverted relative to the fixed outside cone to allow very large rocks to enter the crusher and which crushes rocks fed into the space between

Learn MoreSuperior™ MKIII Series primary gyratory crushers

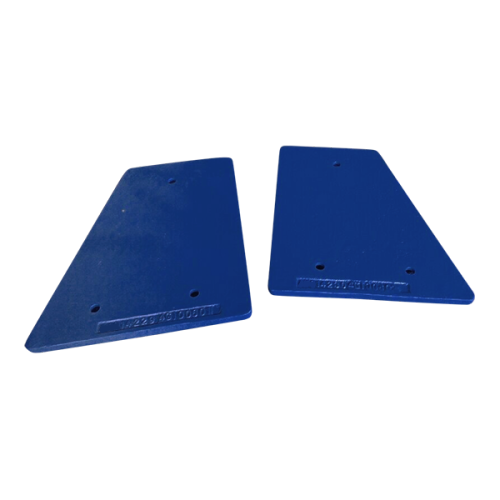

Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development. The improvements to

Learn MorePrimary Gyratory Parts | Gyratory Crusher Parts | CMS Cepcor

CMS Cepcor® crusher service technicians are available to work on primary gyratory crushers worldwide, we provide expert assistance and a complete strip down and re-build service. All CMS Cepcor® compatible crusher parts are manufactured and warranted by CMS Cepcor®, for the avoidance of doubt it is not implied that any of our branded parts originate from the OEM.

Learn MoreSUPERIOR - 60-110E - Primary Gyratory

The new SUPERIOR 60-110E primary gyratory crusher enhance today's crushing needs, and use the latest in design and modeling software.

Learn MorePDF Application guide SUPERIOR® primary gyratory crusher wear partsPDF

Outotec's primary gyratory crusher range includes 4 basic head sizes (65", 75", 89" and 110"), in addition to which the Super Spider upgrade provides two additional larger feed openings. The patented U-shaped spider arms reduce twisting during crush - ing. Arched spider arms create a less restricted feed opening to

Learn MoreUsed Gyratory-crushers For Sale

Buy used Gyratory-crushers from A.M. King Industries. We can help guide you to the best solution for your equipment needs. Transforming the global market for surplus mining equipment 42 x 86 XHD Primary Gyratory Crusher with 600 HP (450 kW), 60 hz drive motor. Manufacturer: NORDBERG. Inventory ID: 3C-283. View Details. Size: 42 x

Learn MorePrimary Gyratory Crusher Parts - CMS Cepcor

At CMS Cepcor® we manufacture reliable and high-quality replacement parts for primary gyratory crushers which are shipped worldwide. Contact us today.

Learn More

Leave A Reply