Fan balancing. Impeller balancing

Here we have 55KW fan in our process supplying air to the burning zone in prehaeating area. This fan was having 5.5mm/s vibration and it was showing it in 1X

Learn MoreMaintain Pump's Operation with Impeller Balancing - PumpMan

Balancing involves adjusting the impeller that zeros out unbalance and eccentricity. To balance a single plane imbalance, weight needs to be evenly distributed.

Learn MoreLarge Impeller Balancing - Case Study

On the blade side, that plane location gives us immediate quantity of material for removal. The idea is to finish balancing knowing the couple, and removing

Learn MoreFan Balancing - IndiaMART

Service Provider of Fan Balancing - Dynamic Balancing Servicing, Dynamic Balancing Of Impeller, Impeller Balancing Services and Impeller Balancing offered

Learn MoreSlurry Pump Impeller Balancing - Tobee Pump

19/08/ · Dynamic balancing equipment is used to position the impeller on a machine driven arbor and measure vibrations caused by centrifugal forces to determine the unbalance. This method has the most sensitivity and accuracy for measuring unbalance in either single-plane or

Learn MoreImpeller Balancing Services in Ogden, Utah

Impeller balancing for two-plane unbalance requires two corrections weights to be added at an axial distance from each other. These processes are extremely precise and designed to provide results that meet strict ISO guidelines with regard to a number of different kinds of equipment. Ogden, Utah Impeller Balancing

Learn MoreFan & Pump impellers | Same day dynamic balancing

Dynamic Rotor Balancing | 35 years experience balancing: Fans, pumps, wheels, rollers & impellers in the heart of the West Midlands.

Learn MoreImpeller Balancing - Tencarva Machinery Company

All impellers, multiple stages assemblies, blower rotors and fans are balanced to a minimum of G 1.0 specification. Tighter balance tolerances significantly

Learn MoreMaintain Pump's Operation with Impeller Balancing

Balancing involves adjusting the impeller that zeros out unbalance and eccentricity. To balance a single plane imbalance, weight needs to be evenly distributed. In a two plane unbalance, sometimes called couple unbalance, it is corrected by adding two correction weights equidistant from each other.

Learn MoreAutomatic Vertical Milling Balancing Machine

Vertical automatic balancing machine, specifically developed for the balancing of brake drum, Brake disc, diff case. pump impeller, train brake disc. assembled clutches on one plane (static). The

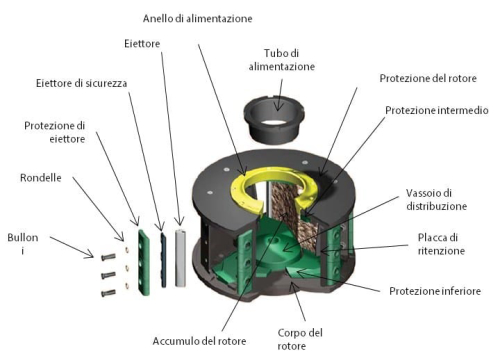

Learn More15 Impeller dynamic balancing process - ResearchGate

Download scientific diagram | 15 Impeller dynamic balancing process from publication: Experimental and Numerical Investigation of Flow Induced Vibration in

Learn MoreRotor Balancing | Fan & Pump impellers | Same day dynamic balancing

Balancing is the process of adding or removing weight to move the mass centreline as close to the true axis as possible. Dynamic rotor balancing works by sensors measuring 2 independent planes and a computer identifying the imbalance in both planes, showing where the compensatory weight needs to be applied or removed.

Learn MoreRotor Balancing | Fan & Pump impellers | Same day

Balancing is the process of adding or removing weight to move the mass centreline as close to the true axis as possible. Dynamic rotor balancing works by sensors measuring 2 independent

Learn MoreDynamic balancing services | Burnley Balancing

Static or dynamic balancing of your rotating components will eliminate excessive vibration and ensure the smooth running of your machinery. Vibration can put considerable stress on bearings, suspensions, housings and foundations, so by balancing your rotors you can significantly reduce machinery maintenance costs and plant downtime.

Learn MoreDynamic Balancing on Pump Impellers - EASA

whether the impeller balance should be checked/ corrected in the balancing machine. Generally, it's not practical to test run a pump to check vibration.

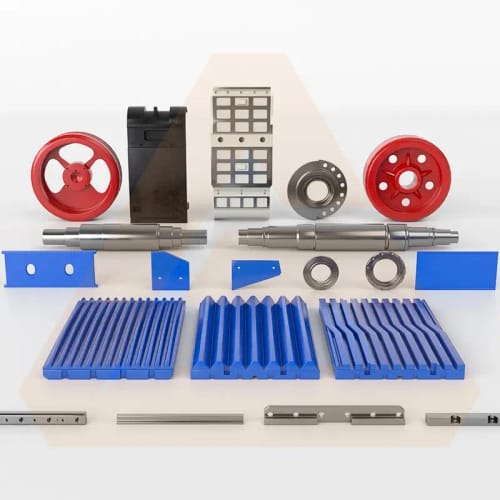

Learn MorePump Impeller Balancers - CIMAT Balancing Machines

Pump Impeller Balancers, At CIMAT, we offer balancing machines for pump impellers, multi-stage pump assemblies and also impeller and motor assemblies. A range of manual and automatic balancing machines are available for every type of impeller and for all production levels. Proven design, Fast delivery, and 24/7 phone support.

Learn MoreWet Balancing Cuts Vibration Up to 70 Percent in Wastewater Pump Impellers

Tests showed a significant reduction in vibration. By introducing wet balancing in its single-channel impellers, the manufacturer reduced vibration levels by 50 to 70 percent. These results mean sturdier and more reliable pumps because the dynamic balancing of the impellers and rotors is essential to prolonging the reliability and functioning

Learn MoreIndustrial Balancing | Vi-TECH | Texas

CNC Machining, Pump Repair, industrial balancing services, rotor balancing machine, dynamic balancing of impeller Industrial Balancing and Machining 6514 Overcrest Lane, Pasadena, TX 77505, Tel: 281-991-6200

Learn MoreBalancing a Large Impeller

1.59K subscribers http://www.koffler.com Balancing a large impeller, for de-watering pump from a submarine dry dock located at Pearl Harbor, Hawaii. KOFFLER has the capability to Dynamic Balance

Learn MoreImpeller Balancing Services - Pump Repair & Emergency ... - PumpMan LLC

Balancing is the procedure by which the mass distribution of a rotor is checked and, if necessary, adjusted in order to ensure that the vibration of the journals and/or forces on the bearings at a frequency corresponding to service speed are within specified limits. In practical terms, balancing corrects unbalance.

Learn MoreThe importance of impeller balancing and inspection

When an impeller is out of balance, the tell-tale signs to look for include: · Elevated vibration and noise levels · High energy use due to imbalances (additional

Learn MoreBalancing Centrifugal Pump Impellers

Balancing Centrifugal Pump Impellers Vibration caused by imbalance in rotating machinery, including pumps, is an important engineering problem. It is

Learn MorePump & Impeller Balancing - SCHENCK USA

Pump & Impeller Balancing. Schenck's Pump & Impeller course is an excellent opportunity for those involved with pumps, compressors and turbines to learn

Learn MoreEasily Impeller Balancing Step By Step

20/02/ · Easily impeller balancing step by step video impeller balancing kaise kare vo bhi step by step mai dekhaya gaya hai. Jisse dekh kar aap bhi impeller balance

Learn MoreWhat Impeller Balance Grade Should be Used to Limit Pump

03/06/2022 · Pump impellers are typically balanced in accordance with International Organization for Standardization (ISO) 1940 balance quality grade G6.3 or better. (ISO 1940 for values relating to other balance grades). It is important to note that the G6.3 is a generality.

Learn MoreBalancing and blade-shaping of a single-blade impeller

We will refer to the influence of the blade outlet angle change and the impeller dynamic balancing on hydraulic parameters of the pump in this paper.

Learn MoreBriefly On The Balance Hole Of Centrifugal Pump Impeller

The balance hole (return port) is mainly used to balance the axial force generated by the impeller when it is working. It reduces the wear of the bearing end surface and the wear of the thrust plate. When the impeller rotates, the liquid filled in the impeller moves from the impeller under the action of centrifugal force.

Learn MoreDynamic Balancing on Pump Impellers - Resource Library

As with most other machines commonly repaired in EASA service centers, dynamic balancing on pump impellers is an important concern.

Learn MoreIndustrial blower impeller field balancing using stroboscope - Signasis

In almost all scenarios with the exception of cooling tower fan, the industrial blower or impeller will be enclosed with a small inspection window opening. For this discussion, we will be considering only single plane field balancing of industrial blower or impeller to simplify the concept. Below assumptions have been taken into consideration:

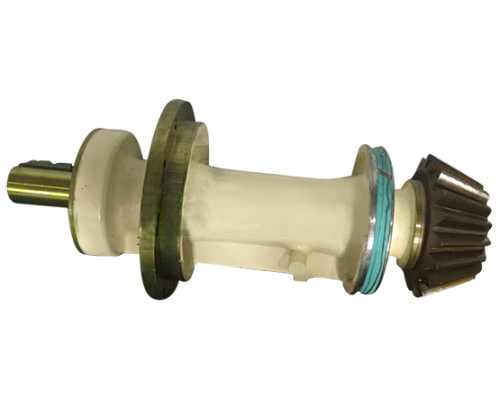

Learn MoreBalancing Pump Impellers - Hines Industries

Pump impellers are generally balanced by removing material, by drilling, milling, or grinding. Horizontal overhung balancers can be fitted with grinding

Learn MoreFollowing Industry Standard Guidelines for Balancing Centrifugal Pumps

Common causes for unbalance in pump impellers include, but are not limited to: Mounting errors during stacking of components Machining and fabrication tolerances Eccentric mounting of components and the rotating assembly Nonsymmetrical rotors Bent shaft due to mechanical conditions or thermal effects Non-homogenous component material

Learn More

Leave A Reply