Know the Difference Between Gear Shaping and Gear Hob

Know the Difference Between Gear Shaping and Gear Hob . Just like any sheet metal is fabricated to form the right mold, shape, size, and so on, gear manufacturing has certain machining processes such as shaping, hob , and so on. Gears are required to be set in motion, rotate, and raise the speed of any machine, industrial equipment

Learn MoreMHI to Unveil 2 High-speed, Fully "Dry-cut" Gear Cutting

The new "GE25A," a gear hob machine, will become available with a newly Easy and simple operation software for setting the machining

Learn MoreGear Hob Machine: Everything You need to Know about Gear

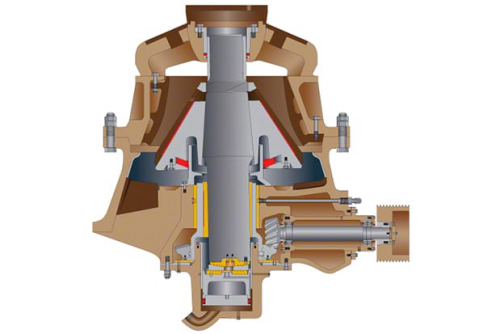

The gear hob machine has two skew spindles, one of which has the gear blank while the other one has the hob. • The spindles are set at an angle from each other,

Learn MoreGear Cutting Machines | Fabricating & Metalworking

Gear cutting machine tools adjust and control cutting speeds for precision production of a specific number of gear teeth, including the milling of circular, holed plates without teeth, hob or cutting out of teeth, broaching or boring through inner surface machining, quenching by heat treatment and grinding of the surfaces and the teeth.

Learn Moregear-hob machine - Britannica

Gear-hob machines use a rotating, multiple-tooth cutting tool called a hob for generating teeth on spur gears, worm gears, helical gears, splines,

Learn MoreGear hob 101 required. | Practical Machinist

As ITW used to say, "Good blanks make good gears." Back your hob out of the way and turn 'er on. Feed the hob in by hand until it just touches

Learn MoreCNC Gear Hob Machine H200 by S&T Dynamics

H200, Machine Tools - Gear Cutting Machine, Korean Machine. CNC Gear Hob Machine. Model. H200 Faster and more precise hob setting. 자료 다운로드.

Learn MoreEverything You Wanted to Know About Gear Hob

A hob machine has two skew spindles, one of which contains the blank, and the other of which contains the actual hob. The type of gear being produced dictates the angles at which these are held to one another. The machine is then set -up to rotate the two shafts at the proper ratio for whatever gear is being produced, while the hob

Learn MoreSetup on CNC Gear Hob Machines | Gear Technology Magazine

Setup on CNC Gear Hob Machines. Duration: 00:00:00. Release Date: July 18, 2016. Setup on CNC Gear Hob Machines from Affolter Technologies S.A. Share.

Learn MoreDevelopment of Gear Hob Fixture Design for Reduction in

Reduction in Machine Setting Time settings of the fixture on the hob machine. There by, Index Terms- Fixtures, Gear Hob , Hob fixtures.

Learn MoreThe Gear Hob Process - Gear Technology

The Gear HobbinglMachine Agear bobbillg machine consistsoffive common elements: • Awork spindle to rotate the work. • A hob spindle to rotate the hob. oA means of rotating the work spindle and hob spindle with a constant of ratio, depending on the number of teeth in the workpieceami the number of threads ill the hob.

Learn MoreGear Hob - Parts, Working, Diagram, Advantages

In hob spur gear the hob teeth are set parallel to the axis of rotation of the blank. For helical teeth bob , the axis of the hob is set over an angle to produce the proper helix. While worm gears are produced with the axis of the hob set the right angle to the gear blank. Generally two techniques are used in the hob process.

Learn MoreMikron gear hob machine - pjn.yukkuri.shop

I've bought a small hob machine which cuts spur gears only. It's a Mikron 112. The machine is complete and working, just needs cleaning and lubricating and a VFD fitted for the motor, I have a full set of change gears and a decent number of cutting hobs.

Learn MorePDF Development of Gear Hob Fixture Design for Reduction in Machine ...PDF

During manufacturing of gears on Hob machine, the time taken for the setting of the hob fixture was very high. Whenever a gear of a new Root Diameter is to be manufactured, old fixture has to be removed & the relevant new fixture has to be installed. For changing of the fixture on the gear hob machine the time required was found out

Learn MoreUsed Hob Machines - Helios Gear Products

Get pricing. Helios offers used hob machines from stock starting at $49,000. These machines are ideal for workpieces up to approximately 7″ OD, and configurations are available that include CNC, mechanical, with automation, and manually loaded. Even used hob machines can be incredibly productive thanks to CNC and automation systems.

Learn MoreWhat is Gear Hob (How is Gear Hob Done?) - Knords Learning

Gear hob is a method of making gear teeth by the help of a rotating cutter called a hob. By using gear hob operation, most of the involute gears are manufactured. Gear hob is a faster and continuous method of gear manufacturing, hence it shows high production rate in less time. Gear hob is used to manufacture spur gears, splines

Learn MoreDevelopment of Gear Hob Fixture Design for Reduction

During manufacturing of gears on Hob machine, the time taken for the setting of the hob fixture was very high. Whenever a gear of a new Root Diameter is to be manufactured, old fixture has to be removed & the relevant new fixture has to be installed. For changing of the fixture on the gear hob machine the time required was found out

Learn MoreGear Hob - Parts, Working, Diagram, Advantages

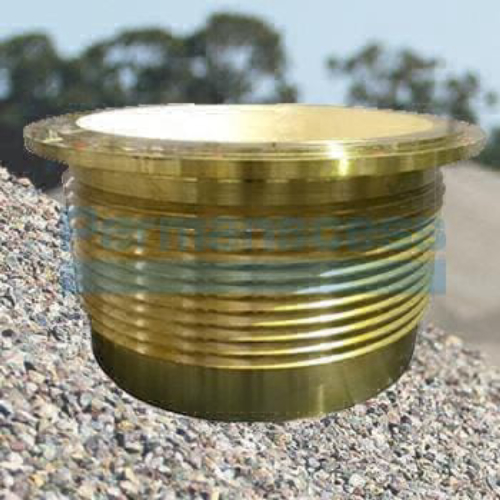

Gear hob is done by using a multipoint cutting tool called gear hob. It looks like a worm gear having a number of

Learn MoreDevelopment of Gear Hob Fixture Design for ... - CiteSeerX

for the other gears ' manufacturing and reduce the no of settings of the fixture on the hob machine. There by, reducing company's cost & time.

Learn MoreIllustration of the worm gear hob with the machine setting

To change the longitudinal crowning from asymmetric to symmetric, a method of modified worm gear hob is proposed. The modification uses a modified machine tool setting and a modified hob

Learn MoreGear Hobber Casting Set - martinmodel

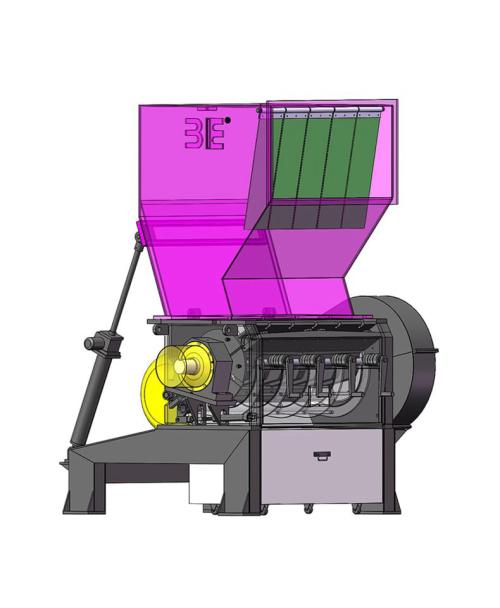

Gear Hobber Casting Set $495.00 Add to Cart The gear hobber is a machine for producing gears by the hob process: a rotating gear blank is fed into a gear hob (in the shape of a worm). The maximum capacity is about 4" in diameter, 20 dp (diametrical pitch), 1.25 module down to 1/10" diameter, 120 dp, 0.2 module.

Learn MoreA Tooth Flank Crowning Method by Applying A Novel Crossed

In the conventional gear hob process, the longitudinal crowning for tooth angle of the hob cutter and work gear as a fixed machine-tool setting.

Learn MoreDiscover how to produce gears - Hob machine

Discover how to produce gears - Hob machine - Gears machining methods most popularStep by Step Machining Process to Make Spurgear. Gear manufacturing r

Learn MoreGear hob machine - The Gleason Works

The hob machine is characterized in that a separate mechanism for hob shifting is not required. The hob shifting, as well as other machine

Learn Moredynamic analysis of the cutting forces in gear hob - CORE

ease adjustment ofthe machine. 3.3 CNC GEAR HOBBING. The early 1970's was an important era in numerical control of machine tools, as.

Learn MoreCNC Vertical Gear Hob Machines – Gear Hob Solutions

Discover the perfect place to get your Gear Hob Machines. Phone No +91 99444 36045 Email [email protected] Get Quote From us. Please fill in the form and we shall get back to you with our best. Name. Email. Phone. Hobbing_Type

Learn MoreFast hob centering device for gear hob machine

fast hob centering device for a gear hob machine. The hob centering device consists of a column, a bracket, a tool setting rack, a tool setting rod,

Learn MoreGear Hobber Casting Set – martinmodel

Gear Hobber Casting Set. $495.00. Add to Cart. The gear hobber is a machine for producing gears by the hob process: a rotating gear blank is fed into a gear hob (in the shape of a worm). The maximum capacity is about 4” in diameter, 20 dp (diametrical pitch), 1.25 module down to 1/10” diameter, 120 dp, 0.2 module.

Learn MoreChina Gear Hob Machine Setting, Supply Gear Hob Machine Setting

Jiangsu Hoston Machine Tools Co., Ltd. [Jiangsu,China] Business Type:Manufacturer , Trade Company. Main Markets: Africa , Americas , Asia , Caribbean , East Europe

Learn MoreFAQ about gear cutting, gear software and gear design - Meshing with Gears

How is a traditional hob machine set up to cut a spur gear? All "traditional" gear hob machines have an Index Constant. This constant, along with the number of teeth to cut and the number of starts in the hob cutter determine the index gear ratio and the index change gears. Some typical Index Constants are: 36, 30, 24, 15, 12, 10, etc.

Learn Moregear hob — Translation in French - TechDico

Development of gear hob fixture design for reduction in machine setting time For a Gear hob fixture also there are multiple designs possible.

Learn More

Leave A Reply