CONTI CordProtect < Belt Monitoring Systems < Digital Solutions

High-performance cord monitoring systems for steel cord conveyor belts Key Features Cord Damage Detection Belt Splice Monitoring User-defined alarm levels Interactive display Damage reports Reporting with automatic splice identification and alarm system Robust design for all environmental and weather conditions Cord Damage Detection Functionality

Learn MoreBelt Scanner Portable Condition Monitoring - Conveyor Belt Monitoring

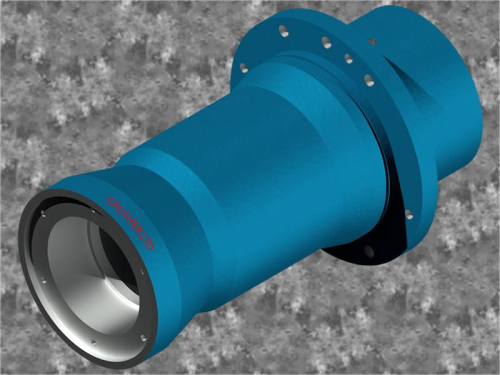

The Belt Scanner Portable Hi-Resolution sensing device consists of a stainless steel Transducer fabricated to over-span the width of the largest target conveyor belt. This allows for belt wander. The Transducer detects; 1. Broken cords 2. Rusted / corroded cords 3. Kinked cords (vertical plane) 4.

Learn MoreBelt Conveyor Monitoring | 4B UK - 4B Braime

4B has a wide range of sensors for monitoring the various parts of your belt conveyor. The most common areas for monitoring include: bearing temperature,

Learn MoreMCube Belt Thickness Monitoring (BTM) - REMA TIP TOP

The Belt Thickness Monitoring System (BTM) continuously measures wear and wear characteristics on conveyor belts by use of ultrasonic sound-waves, these sensors

Learn MoreConveyor Belt AI Monitoring And Predictive Maintenance System

The system monitors three conveyor belt stations - filler, canning, and labeling. Filling lines - how much liquid is in a bottle - can be either too low or too high, depending on the nature of a mishap: a deformed bottle, degraded water seal, etc. The system can detect when a bottle is not filled properly and alert the personnel.

Learn MoreCONTI CordProtect < Belt Monitoring Systems < Digital

CONTI CordProtect has been monitoring steel cord belts in mining and industrial applications since 2008. This reliable system is capable of detecting cord damage and prioritizing the damage based upon the size and location, while also monitoring for damage growth. By detecting critical damage, the issue can be proactively addressed before it

Learn MoreUsing Remote Conveyor Monitoring to Eliminate Unplanned Downtime

The remote monitoring technologies available today include: Camera systems for detecting tears in covers. Idler roller vibration monitoring. Belt tracking/misalignment detection. Bearing temperature monitoring. Gearbox/reducer vibration monitoring. Motor current draw (for tracking energy consumption and belt load) Oil temperatures and pressures

Learn MoreABB Ability Condition Monitoring for belts

ABB Ability™ Condition Monitoring for belts is an advanced digital service tailor made for predictive maintenance of conveyor belts, that collects and

Learn MoreCBGuard Conveyor Belt Monitoring - Introduction

CBGuard - he ultimate conveyor belt monitoring system.

Learn MoreMining guide: Conveyor belt monitoring and control in mines

Dec 19, · Mining guide: Conveyor belt monitoring and control in mines One of the most important aspects of a successful mining operation is the effectiveness of a project’s conveyor belts, transporting material too bulky and heavy to be carried by hand to where it needs to be, and functioning in a safe manner. By JP Casey

Learn MoreNew Technologies for the Protection of Conveyor Belting

Another method of condition monitoring revolves around the measurement of belt thickness at regular intervals in order to determine the wear

Learn MoreContinental launches radar-based monitoring system for

Continental has launched the Conti Load Sense monitoring system, based on 2D radar technology to measure material flow on conveyor belts.

Learn MoreMonitoring Belt Conveyors with a Speed Switch - Electro

Monitoring Belt Conveyors with a Speed Switch A Speed Switch is used to alarm an operator of any undesirable or critical speed condition of the monitored shaft such as rotating too fast, too

Learn MoreConveyor Belt Monitoring | Monitoring Systems

CONVEYOR BELT MONITORING. Uptime and safety are critical factors for conveyor belt operators. A key focus of our system is monitoring temperature change as coal is transported

Learn MoreCaddis Conveyor Belt Monitoring System - CADDIS systems

Conveyor Monitoring Caddis Systems is the perfect solution for companies that depend on their conveyors to efficiently run their business. Conveyor Monitoring If it’s critical that you know your conveyor speeds to track production as well as track cycles or revolutions then Caddis is a cost-effective solution to putting this data in front of you.

Learn MoreConveyor Monitoring - Assure by Terra15

The Treble is an intelligent device that turns any optical fiber cable into hundreds or thousands of vibration sensors along a conveyor belt. In effect, every

Learn MoreCondition Monitoring of Critical Mining Conveyors - Emerson

Effectively monitoring belt conveyor systems in open-pit mines ensures maximum uptime by employing specialized condition monitoring systems to maintain machinery health. Online condi- tion monitoring of conveyers supplies real-time machinery health information back to the control room and maintenance shop.

Learn MoreConveyor Belt Monitoring System - Accuopt Thermal Imaging Systems

Accuopt's Conveyor Belt Monitoring system is a reliable system, which increases plant, personnel, and equipment safety. The System uses Accuopt make ThermCAM-80 thermal cameras, which provide continuous monitoring. ThermCAM-80 is an LWIR, 80×80 pixel resolution thermal camera which measures temperature with precision.

Learn MoreBelt Management | Becker Mining Systems AG

Belt Management / Conveyor Control For the monitoring of steel cable and plastic belts, inductive loops are embedded in the belt. Once installed, the BRS2 will detect the loops on the conveyor, define and number the loops and create its own image of the belt and its loops in real time. With a loop diagnosis in real time, BRS 2 constantly

Learn MoreCONTI RipProtect < Belt Monitoring Systems < Digital Solutions

High-performance inductive belt rip detection systems for conveyor belts with sensor loops. CONTI RipProtect is a permanent Radio Frequency (RF) system that detects and minimizes longitudinal conveyor belt rips by monitoring the condition

Learn MorePDF Condition Monitoring of Critical Mining Conveyors - EmersonPDF

Conveyor systems that move heavy and bulky substances such as mined materials necessarily operate at low speeds to accommo-date high loading. These types of belt conveyors come in various configurations, but all share certain characteristics that make them suitable for condition monitoring. Belt conveyor systems generate certain and predictable

Learn MoreConveyor Belt Monitoring | Rampart Detection Systems

Conveyor Belt Monitoring Conveyor belts are the lifeline of mining operations, Rampart has developed systems for monitoring steel cord conveyor belting, for detecting conveyor belt

Learn MoreConveyor Belt Monitoring System - Accuopt Thermal Imaging

Conveyor Belt Monitoring System A conveyor belt is an important tool in many industries to carry raw material and products (like coal, clinker, etc.) from one place to another. While carrying these materials there is high chances of sudden combustion due to the presence of overheated bearing or rollers as materials like coal are highly combustible.

Learn MoreConveyor monitoring - CSIRO

Maintaining conveyor belts in mines is a significant problem, with conventional monitoring methods unreliable, time consuming, labour-intensive, costly – and

Learn MoreDigitalize Conveyor Belt Roller Monitoring - Yokogawa

Ability to monitor long and wide conveyor belts in real‐time. • HMI graphical drawings enable excellent visibility for operators. • Centralized monitoring and

Learn MoreConveyor belt monitoring system and method - Google Patents

A conveyor belt condition monitoring system having a signal emitter for emitting at least one detectable signal disposed on one side of a conveyor belt,

Learn MoreConveyor belt temperature monitoring and fire detection

Monitoring of long conveyor belt installations traditionally requires a large number of temperature probes, each of which must be functional to ensure sufficient fire protection. Instead of a costly multi-sensor setup, an entire conveyor belt installation can be monitored by a single LIOS DE.TECT optical linear heat detection system.

Learn MoreConveyor belt, Inspection and Condition Monitoring (running

Apr 10, · Conveyor belt, Inspection and Condition Monitoring (running) - SA Mining Solutions • SAMS • SAMS, is a leading supplier of mining equipment, crushing, and material handling solutions. 10 Apr Conveyor belt, Inspection and Condition Monitoring (running) Wilna Jordaan Post author

Learn MoreConveyor belt monitoring and control: Mining guide - Carroll Technologies

Conveyor Belt Monitoring and Control in Mines One of the most important aspects of a successful mining operation is the effectiveness of a project's conveyor belts, transporting material too bulky and heavy to be carried by hand to where it needs to be, and functioning in a safe manner. GET IN TOUCH

Learn MoreBelt Guard Conveyor Belt Monitoring - Beltscan

Conveyor Belt Monitoring Our Experience Beltscan has been helping belt conveyor owners maximise the safe working life of these assets since 1979. Barry Brown, our Chairman, was the first person in the world to offer commercial conveyor belt monitoring. The condition monitoring of belting started in 1980.

Learn MorePDF Continental Belt Monitoring Systems Conveyor Belt Protection Devices ...PDF

CONTIÆ SurfaceProtect is an online laser system that monitors the surface of the conveyor belt. The system evaluates the cover condition for cuts and gouges or large impact damage events. Data is analyzed and reported with the position and dimensions of all surface damages.

Learn More

Leave A Reply