Failure Analysis of Jaw Crusher | China Crusher | Mesto

7/7 · July 07, . Jaw crusher is the key crusher equipment for stone crushing production. Many customers will meet various kinds of fault problems during production process, which will affect the whole production schedule. Here, We summarizes the common failure and treatment of the jaw crusher. 1. The main engine stops suddenly.

Learn MoreJaw Crushers - MEKA Crushing & Screening Plants

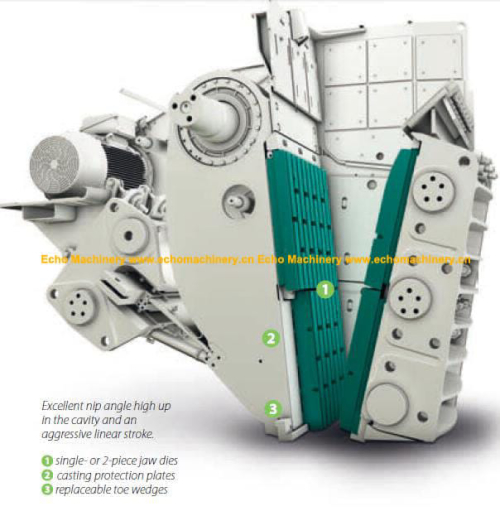

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher's two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds

Learn MoreJaw Plate For Sale | We Source Crusher Jaw Plates

A jaw crusher is one of the main type of crushers used in mining operations, quarries and ore processing plants. A jaw crusher reduces the size of large rocks and ore through compression. The rock remains in the jaws of the crushing machine until it is small enough to pass through the gap towards the bottom of the jaws. Showing 1-12 of 26 results

Learn MoreJAW PLATES - Precision Casting

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing

Learn MoreKenco Longer Wearlife Parts | Jaw Cheek Plates

25" with crushed Tungsten Carbide for longer wearlife; Wear surface hardness of 90 Rockwell A at time of installation; Less crusher downtime, fewer cheek plate

Learn MoreCrusher Jaw Plates For Popular Brands By Hunan JY Casting

Premium Crusher Jaw Plates. The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed

Learn MoreJaw Crusher Wear Parts - Columbia Steel Casting Co., Inc

Columbia Steel manufactures the world's largest number of jaw designs. Wear parts for all popular jaw crushers, include: jaw dies, cheek plates, and more

Learn MoreKnow-how - RUBBLE MASTER

The jaw crusher consists of a fixed jaw plate which is mounted within the the two jaw plates, reducing in size as it gets lower in the crushing chamber

Learn MoreJaw Crusher Plate Material - MGS Casting

3/25 · Jaw Crusher Plate Material. The heavy duty machines use in the first mechanical stage of comminution are mainly jaw crushers. The distinctive feature of t his class of crusher is the two plates which open and shut like animal Jaws (Grieco and Grieco, 1985), this jaw is called jaw crusher plate. The crusher jaws are set at an acute angle such

Learn MoreJaw Crusher Parts - Wear Parts For Industry | Qiming Casting

Mn14Cr2 Jaw Plates. Mn14cr2 jaw plates are used in crushing soft stones. For example, it has a good life when crushing the easy and non-abrasive blasted rock, non-abrasive gravel, and non-abrasive round rock. Mn18Cr2 Jaw Plates. Mn18Cr2 is the most popular material for casting jaw crusher jaw plates.

Learn MoreRock Crusher Jaw Plates - Alibaba

Get back to mining with wholesale rock crusher jaw plates from Alibaba's vast assortment of mining machine parts from hundreds of manufacturers, suppliers,

Learn MoreApplication of The New Shape Crushing Plate in Machine

a double toggle jaw crusher are presented. This process was carried out on six sets of crushing plates. The first three of them are used in industrial

Learn MoreJaw Crusher – Toggle Plate Seating AREA | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher plate – over 6,550,232 jaw plate, check plate, toggle plate are the spare parts of jaw crusher main material is high manganese steel.We can manufacture different plate Jaw Crusher,Jaw Crushers for sale,Used Jaw Crushing Machine

Learn MoreDesign and Analysis of Swing Jaw Plates of Jaw Crusher

The Swing Jaw Plates which is fixed at BOTTOM SURFACE OF THE Swing Jaw Plate is vibrated to obtain the natural frequency, mode shapes and deflection with

Learn Morejaw crushers for all your needs - Lutze Process

Low jaw plate wear. • Large feed acceptance capability. These four factors are closely linked and the jaw crusher provides a good balance. The de-.

Learn MoreJaw Crusher Plates - Wear Parts For Industry | Qiming Casting

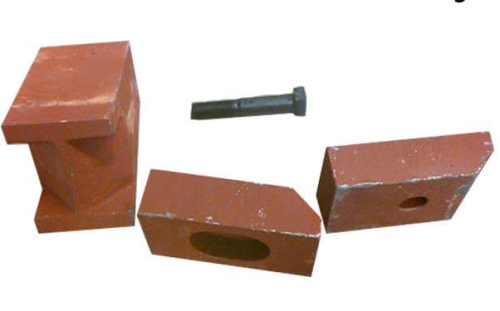

Our foundry had succeeded to offer jaw plates for crusher, crusher and other famous brands.On the other hand, Qiming Casting also offer a variety of manganese contents, from 14% up to 22% for the more demanding applications. In some means, we also improve material choice and casting technology. Wedges Wedges

Learn MoreJaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

The two Jaw Plates are the main working part inside the crusher. One Jaw plate (Fixed plate) is positioned vertical and fixed on the front part wall inside the crushing chamber, the other Jaw Plate (Movable Jaw Plate) is in inclined position opposite the Fixed Jaw Plate. The electric motor drives the Belt and Pulley to make the Movable Jaw

Learn MoreJaw Dies / Jaw Plates / Moveable Jaws / Stationary Plates

Jaw Dies / Jaw Plates / Moveable Jaws / Stationary Plates for Powerscreen 900×600 Jaw Crusher. If you need replacement crushing products for virtually any

Learn MoreJaw Crusher Liner, Swing and Stationary Jaw Plate

As the preferred equipment for coarse crushing, the aggregate industry has high requirements for the jaw plate of the jaw crusher. Jaw crusher liner material In general, the jaw plate is made of high manganese steel. The manganese steel content of Rayco's products ranges in 12-14%, 18% and 20%. Jaw crusher liner manufacturer

Learn MoreJaw Crusher Liner Plate Design & Profile Shapes - Mineral

7/22 · Jaw Crusher Liner Plate Design & Profile Shapes. Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates. This type of

Learn MoreHow to Choose the Right Jaw Plates for Jaw Crushers - Ware Resistance

A jaw crusher crushes stone or ore using large steel crushing plates (jaw plates) that move in two converging tracks with an adjustable gap width. Raw material enters at the top of these tracks, and as it slides down, it is squeezed by these plates until finally getting jammed as its size prevents further convergence.

Learn MoreToggle Plate | Genuine Alternative Jaw Crusher Parts | GTEK

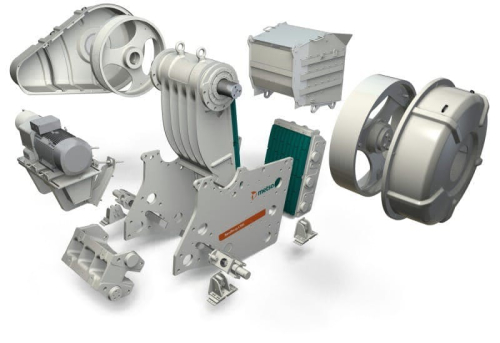

Toggle Plate is a simple & low-cost but very important part of jaw crusher. It is usually made of cast iron, and it is used to hold the lower part of the jaw in position, it also serves as a safety mechanism for the entire jaw. If something that the jaw crusher cannot crush gets into the crushing chamber accidentally and it cannot pass through

Learn MoreCheek Plates and Jaw Crusher Parts | Clifton Steel

The cheek plates lining the inside of the jaw crusher cavity are subject to both high stress (during the crushing cycle) and low stress (between crushing cycles) abrasion. This abrasion wears away the material from which the cheek plates are made. Clifton Steel's Tensalloy™ Blue material is a tough, abrasion resistant material designed for

Learn MorePDF) Selected design issues of toggle plate selection on the

PDF | The article presents the problem of increasing the performance of the jaw crusher, reducing the crushing power and moment.

Learn MoreJaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale

Jaw Plate – Jaw Crusher Wear Parts. Jaw Plate is the main wear part of Jaw Crusher, including fixed plate and jaw plate . We can produce a variety of meet the requirements of the jaw plate according to the customer’s model . Because of the use of manganese content of 13% to 30% of the high manganese steel and ultra-high manganese steel, and

Learn Morejaw plate crusher parts, China jaw plate crusher parts, jaw plate

China jaw plate crusher parts catalog and jaw plate crusher parts manufacturer directory. Trade platform for China jaw plate crusher parts manufacturers and global jaw plate crusher parts buyers provided by

Learn More6 Factors to Consider When Choosing Jaw Plate for Crushing Operation

Material Hardness: When choosing jaw plates, the hardness of the materials is an important consideration. It ensures the toughness and strength requirements of the corresponding jaw plate. It is important that the plates must attain this feature to increase overall jaw crusher life. Specifications: The selection of jaw plate mainly depends upon

Learn MoreC Series Crusher Jaw Plates By Hunan JY Casting

No matter you are running the C63 or the C160 jaw crusher, no matter your C series jaw plates are one-piece designs or two-piece designs, Hunan JY Casting carries the premium jaw plates for your unit. In most cases, we have the part on the shelf and ready for immediate shipment. In some cases, Hunan JY Casting carries has even improved the

Learn MoreCJ jaw plates, standard solutions — SRP

Our patterns include Wide Teeth (WT), Corrugated (C), Coarse Corrugated (CC), Sharp Teeth (ST), Heavy Duty (HD), Heavy Duty Ultra-Thick (UT). The application area determines the most

Learn MoreJaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale - Willing

Because of the use of manganese content of 13% to 30% of the high manganese steel and ultra-high manganese steel, and the unique heat treatment, our products possess strong wear resistance and long service life. Our jaw plates are widely used on mining, construction, chemical, cement and metallurgical industry. Details Videos Downloads Parameters

Learn MoreJaw Liners, Jaw Plate Material And Manufacturer | Quarrying

The jaw crusher liner is also called the tooth plate, which is an important part of the jaw crusher. A set of jaws is usually composed of movable jaws and fixed jaws. According to different models of jaw crushers, the jaws also have the same size and model. As the preferred equipment for coarse crushing, the aggregate industry has high

Learn More

Leave A Reply