Raw Coal Spillage Or "Pyriting

Coal dribble or spillage is raw coal that is rejected through the pulverizer's pyrite discharge. This is caused when the velocity across the pulverizer throat is too low to maintain suspension of coal. Air velocities through the pulverizer throat should be 7,000 to 7,500 Fpm when calculated on a free jet basis.

Learn MoreReliable Coal Pulverizers and Mills » Babcock & Wilcox

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. B&W's pulverizers, found at power stations throughout the world.

Learn MoreWhat are pulverizers used for? Explained by FAQ Blog

What does a pulverizer do to coal? Coal pulverizers are used to dry, grind and classify. Drying is achieved as hot gas passes through the pulverizer and removes moisture from the pulverized coal. Pulverized coal ignites more efficiently than raw lumps of coal, thus the overall efficiency of the furnace increases if it is fired on pulverized

Learn MoreCe coal pulverizer - lkldhx.camboke.shop

A pulverizer (coal pulverizer) is installed for this purpose, and pulverizes pieces of coal several centimeters in diameter down to fine particles. The pulverizer includes pulverization, drying and classification functions.. Assumptions: Bituminous coal at $89 delivered. An average ash content of 10%. An average LOI of 8-10%.

Learn MorePULVERIZER ROLLS - Industrial Wear Solutions

With over 35+ years of experience, RPM is the industry leader in rebuilding coal pulverizer rolls. RPM offers a variety of chrome carbide overlay options

Learn MoreVertical Grinding Mill (Coal Pulverizer) Explained - saVRee

Coal pulverizers are used to dry, grind and classify. Drying is achieved as hot gas passes through the pulverizer and removes moisture from the pulverized coal. The hot gases used should have a low oxygen content, this reduces the likelihood of accidental combustion within the mill.

Learn MoreCoal Pulverizers Market Report | Global Forecast From 2022 To 2030

Global Coal Pulverizers Market by Type (Low Speed Coal Pulverizer, Middle Speed Coal Pulverizer, High Speed Coal Pulverizer), By Application (Construction Industry, Metals and Mining, Glass and Ceramics, Other) And By Region (North America, Latin America, Europe, Asia Pacific and Middle East & Africa), Forecast From 2022 To 2030

Learn MoreCoal Pulverizer Maintenance Improves Boiler Combustion - POWER Magazine

Acceptable standards for best low-NO x burner performance are coal fineness of 75% passing a 200-mesh sieve and less than 0.1% remaining on a 50-mesh sieve. Fuel balance should be within the range

Learn MorePDF Optimum Operation and Maintenance of EL PulverizersPDF

The procedure applied to extinguish a fire on an in-service pulverizer is as follows: 1. Increase the raw coal feed to the pulverizer to the maximum pulverizer capacity. 2. Make the transition from hot to cold air operation. Avoid making sudden changes in air flow through the pulverizer. 3. Monitor pulverizer outlet temperature.

Learn MorePDF A Comparison of Three Types of Coal Pulverizers - Babcock PowerPDF

As the mill rotates, the balls cascade and pulverize the coal by impact and attrition. The pulverized coal is then conveyed by air to centrifugal classifiers. Properly sized pulverized coal exits the classifier into coal piping for transport to the furnace. Oversized pro- duct is, however, separated and returned to the mill for further grinding.

Learn MoreLeading Coal Pulverizers and Mills - Babcock & Wilcox

Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of

Learn MorePDF Coal Pulverizer and Coal Crusher Reliability | MobilPDF

Coal pulverizers/crushers Industries • Power generating stations Key applications • Gears — worm and helical, bevel combinations • Roller element bearings Challenge: Coal pulverizer reliability. Repairs and even routine maintenance are time-consuming and costly due to difficult operating conditions. Operating temperatures can be high and

Learn MorePulverizer Fire and Explosions

Explosions in a pulverized coal system are normally called “puffs.” A mill puff is an explosion in the mill system caused by an explosive combination of coal,

Learn MoreDevelopment and operating experience with inerting systems

Fire protection systems for reducing the hazards of fires and explosions of coal pulverizers and bunkers and experience in operating these

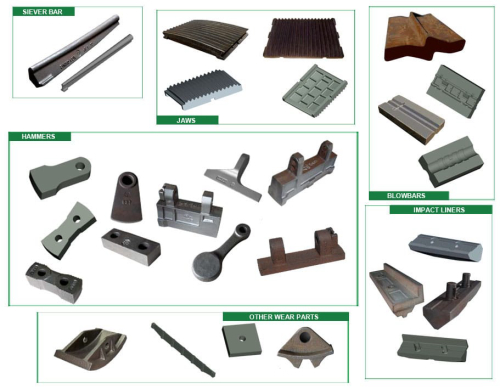

Learn MoreCoal Pulverizers Wear Liner - WALDUN | Abrasive Enhanced

Coal pulverizers wear liner is used to protect the cylinder from direct impact and friction of the grinding body and materials. At the same time, different types of liners can be used to adjust the movement state of the grinding body to enhance the abrasive effect of the crushing body on the materials. It is helpful to improve the crushing

Learn MoreCoal Pulverizer at Best Price in India

We are best in manufacturing coal pulverizer machine. It also known as koyla chakki, coal mill.We manufacturing pulverisers for reheating furnace as per

Learn MorePDF B&W ROLL WHEEL PULVERIZERS - Babcock & WilcoxPDF

pulverizer the pulverizer of choice for coal-fired boiler operators and owners. Established in 1867, Babcock & Wilcox is a global leader in renewable, environmental and thermal technologies and services for power and industrial applications. For more information or to contact us, visit our website at www.babcock.com.

Learn MorePulverizer Equipment - Information Archives - Babcock Power

World-Proven Coal Pulverizer Technology Debuts in the U.S.. READ MORE

Learn MorePulverized Coal Injection (PCI) System Market Size and Share 2022

Pulverized Coal Injection (PCI) -system Markedssegmentering analyse: Den Pulverized Coal Injection (PCI) -system Markedet er delt basert på type, sluttbruk industri, og anvendelse. Veksten i de ulike segmentene vil hjelpe deg å få kunnskap om de ulike vekstfaktorer som forventes å gjennomsyre markedet som helhet, og tenke ut ulike

Learn MoreHolmes Coal Pulverizers - Measur

These bench-type pulverizers are recommended for reducing coal or coke from No.4 to No.60 sieve size. Light duty LC-350 has manual feed from the 1L feeder

Learn MoreCoal Pulverizer | Crusher Mills, Cone Crusher, Jaw Crushers

Coal Pulverizer, Coal Pulverizer Mill, Coal Mill Pulverizers. Machinery is a manufacturer of coal pulverizing equipment. The four most common types of coal pulverizers are: ball pulverizer, impact pulverizer, vertical roller

Learn MorePDF COAL PULVERIZER DESIGN UPGRADES TO MEET THE DEMANDS OF LOW NOx BURNERSPDF

Coal pulverizer design and operation is an important element integral to the long term success of Low NOx combustion systems. The increased use of Low NOx burners in the past 10 years has instigated a need for further development of coal pulverizer technology in an effort to ensure efficient operation of a power boiler for minimizing gaseous

Learn MoreCoal mill pulverizer in thermal power plants - SlideShare

3. 2.Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the

Learn MoreGet Latest Worldwide Coal Pulverizers Market Research Study by HTF MI

Worldwide Coal Pulverizers Market In-depth Research Report 2022, Forecast to 2028. HTF3413447. Report Format PDF. Pages 112. Views

Learn Morecoal pulveriser - SlideShare

6. FIRING DIRECT FIRING Coal is ground and is directly carried from the Pulverizer to the Furnace by use of Pressurized air. Pressurized Air from Primary Air Fans goes to the Pulverizers. Sufficient temperature is maintained for drying of coal and moving the Pulverised Coal to the furnace without settling. 7.

Learn MoreBoilers machinery : Coal Pulverizer - Mitsubishi Heavy Industries, Ltd

Boilers machinery : Coal Pulverizer [ Thermal Power Plant ] [ ENERGY ] Pulverizers (coal pulverizer) are used to pulverize pieces of coal into fine particles (100μm) before placing into a boiler, to ensure efficient combustion. Pulverizers have three functions, pulverization, drying and classification.

Learn MoreBoiler Mill and Coal Pulverizer Performance | GE Steam Power

Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions

Learn MorePulverizer Optimization Components - Storm Technologies, Inc

The important elements of pulverizer performance are fineness, fuel distribution, coal (pyrites) rejects, and primary airflow calibrations. Optimizing pulverizer performance is a prerequisite for optimum furnace combustion. About three-fourths of the 13 Essentials are pulverizer, primary air, and fuel line related.

Learn MoreCoal Pulverizers Market Size 2022: Expansion Strategy ... - MarketWatch

The Expresswire) -- The Global “Coal Pulverizers Market” report covers leading companies analysis, which incorporates gross profit, volume,

Learn MoreSouthwestern Corporation - Pulverizer, Coal Mill, Coal Power Plant

Southwestern's primary business is the design, manufacture and servicing of performance modifications and upgrades for coal pulverizers. Our work force is experienced and familiar with the requirements and demands of our electric power generation and cement plant customers. As a result, customer service is our top priority.

Learn MoreCoal Pulverizers Market: Global Industry Trend Analysis

The industrial output and retail sales is growing at a steady pace driving the growth of Coal Pulverizers systems in the coming years.

Learn More

Leave A Reply