Crusher Liners - H-E Parts

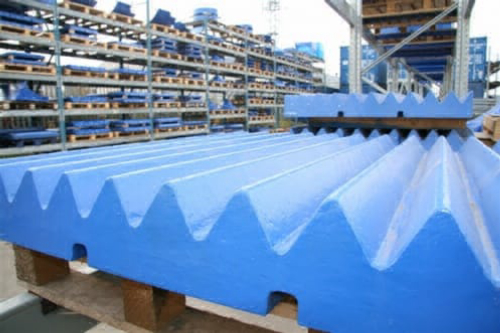

H-E Parts has built a reputation on the reliability and performance of its CME™ range of manganese crusher liners, which are designed to be fully compatible

Learn Morejaw crusher plate-jaw liner - SHANVIM

JAW CRUSHER PLATE-JAW LINER. Short Description: Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the

Learn MoreLiner wear in jaw crushers

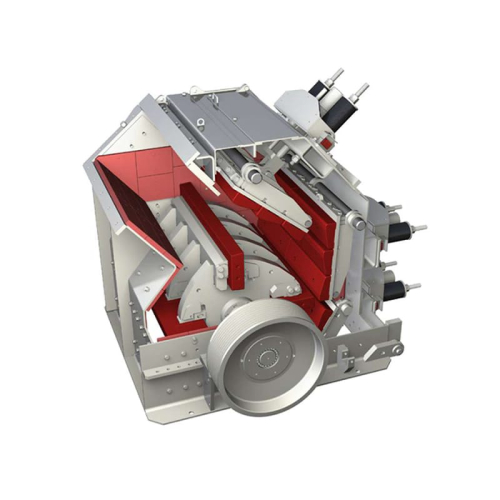

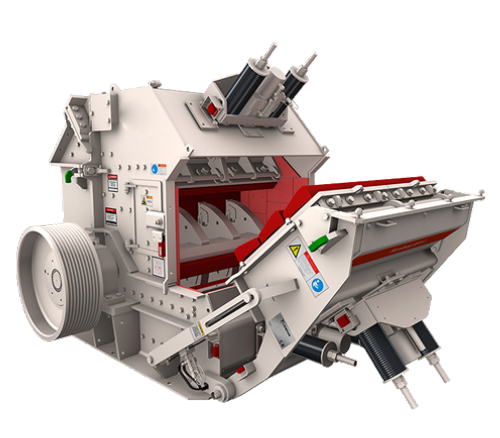

Rock material is fed into the top of the crusher. The rotating eccentric shaft and the link give the right liner an oscillating motion that will crush the

Learn MoreAR Steel Crusher Liners - Crusher Wear Liner Supplies - Ford Steel

Ford Steel offers Wearalloy 400, 450, 500, Nickel Chrome Plus Plate and Mangalloy plate up to 4-inches thick for AR steel crusher liners in impact, jaw, cone and other types of crushers.

Learn MoreLiner wear in jaw crushers - ScienceDirect

Using a small jaw crusher, the wear of the crusher liners has been studied for different settings of the crusher. The experiments have been carried out using quartzite, known for being very abrasive. Crushing forces have been measured, and the motion of the crusher has been tracked along with the we the crusher liners.

Learn MoreJaw Crusher Liner Plate manufacturers & suppliers

China Jaw Crusher Liner Plate manufacturers - Select 2022 high quality Jaw Crusher Liner Plate products in best price from certified Chinese

Learn MoreCheek Plates/ Side Liners for 900×600 Jaw Crusher

Cheek Plates/ Side Liners for 900×600 Jaw Crusher. Samscreen proudly provides replacement crushing products for a vast array of crushing scenarios.

Learn MoreCrushed Fines | Acme Sand & Gravel

Crushed Fines and also known as Quarry Dust, is a form of fractured gravel chips and fine dust used to solidify the base under patios and walkways. The Sub-Base is laid above the ABC or Sub-Grade at 1″ to 2″ inches on light weight traffic areas like pathways and paver patios. Cross-Section layers that make up a mortar-less or "dry-laid

Learn MoreCrusher Liner Glue | Crusher Mills, Cone Crusher, Jaw Crushers

640-5439-0000, Heavy Duty stone Pill Crusher - 64-5439 . Mabis DMI Healthcare Pill Crusher, 2" x 3 -1/4 . Torbot Group Inc Skin Tac "H"™ Adhesive Barrier . First Quality Prevail® Pant Liner Elastic Large .

Learn MoreJaw Plate Manufacturer | Bowl Liner | Blow Bar - Casteel Foundry

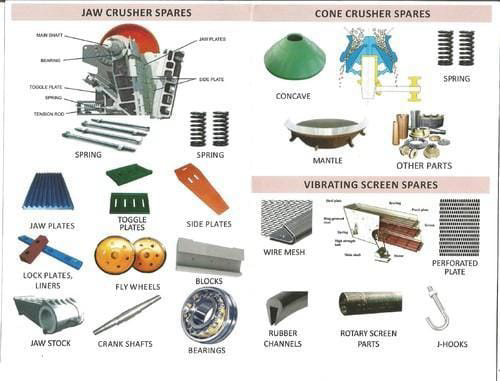

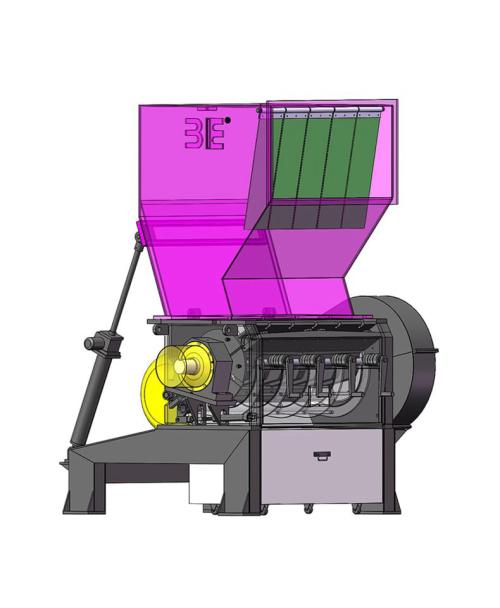

Our full-line of products from VSI Parts bucket Teeth ,hammers,blow bars To large Concave, Mantle , Jaw plates, Grates Mill Liners and much more have been highly recognized among customers and used in wide range of applications.

Learn MoreDENP Industrial

DENP Industrial is a Cone VSI Crusher Wear Parts,jaw crusher wear parts liner plate, wear parts,Double Roller Crusher and Crusher wear parts manufacturers from China,welcome to contact us.

Learn MoreWorld-Leading Crusher Liners - CMS Cepcor

CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw crushers and various

Learn MoreJaw Liners, Jaw Plate Material And Manufacturer

The jaw crusher liner is also called the tooth plate, which is an important part of the jaw crusher. A set of jaws is usually composed of movable jaws and

Learn MoreJaw Crushers | McLanahan

Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn MoreJaw Crusher Liners | Foreman Equipment

OEM Crusher wear parts designed to match original design specifications ensuring the best performance from jaw, cone, and impact crushers. Office - Toll Free: 888-852-9021 | 44109

Learn MoreJaw Crusher Liners – Tempus Steel

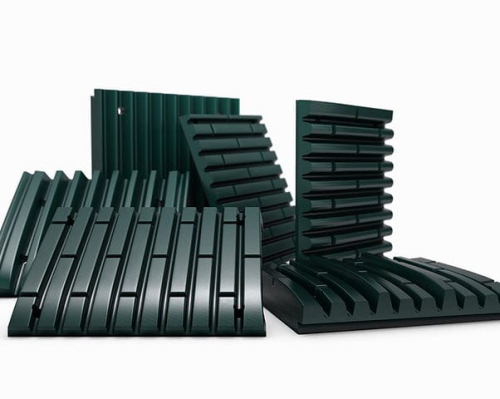

Jaw Crusher Liners. Selecting the right jaw profile can not only significantly improve jaw crusher performance but also secondary crushing efficiency by generating more accurate and more desirable product sizing. This not only provides better production efficiency but can also yield better wear performance and an overall lower cost of production.

Learn MoreChange crusher liners - Wear Parts For Industry | Qiming Casting

Check the following types: On the new crusher liners, place a mark on the adjustment cap driver ring where the pinion tooth makes contact with a driver ring tooth. Keep an record of the number of teeth that used to compensate for liner we crusher liners. Before moving the bowl , record the total number of teeth the driver ring has moved

Learn Morecrusher mantle concave liner, jaw plate, jaw liner, all kinds of

crushtechs specialized in all kinds of crusher and crusher parts.cone liners, jaw liners, cone mantle liner, concave liner, jaw plate, impact crusher parts,

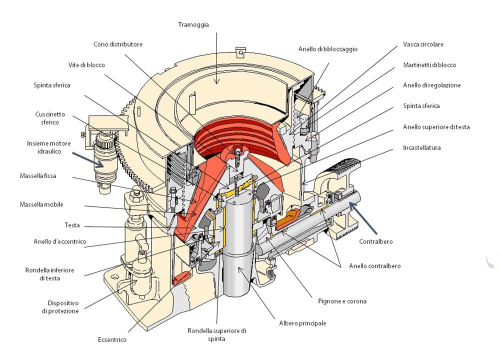

Learn MoreCone Crusher Liners | Crushing Wear Parts

Quick deliveries – Large inventory of crusher wear parts for major cone crushers, gyratory crushers, jaw crushers, impact crushers and roll crushers. CUSTOMER

Learn MoreHow to Change Jaw Liners | Pilot Crushtec

After a new jaw liner installation, rotate the single piece jaw liner when 30% of the tooth profile is worn. Rotate a second time when the tooth profile at the bottom of the jaw liner is completely

Learn MoreCrusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 2

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Top models for sale in HILLSBORO, OREGON include C3R and C4

Learn Morecrusher wear liner cone crusher jaw plate size china factory big

Mantle Bowl Liner Concave, Cone Crusher Wear Parts. Mantle, Bowl Liner and Concave are the main wear part of Cone Crusher. We provide the matching products according to the customers' machine type. The product mainly uses high manganese steel material, for example Mn14Cr2, Mn18Cr2, Mn22Cr2 and so on. Our cone parts are widely used on mining

Learn MoreJaw crusher parts - Outotec

s wide jaw crusher parts range consists of spare parts and wear parts. to ensure an efficient and safe liner change-out for your jaw crusher.

Learn MoreJaw Crusher Parts – Wear Spare Parts – Gdoo Mining

Jaw Crusher Parts. Jaw plates, jaws, jaw liners, fixed jaw plate, movable jaw plate, swing jaw plates, rocky crusher jaws, jaw crusher plates. 18% MANGANESE Standard fit on all Jaw & Cone crushers. A good all round liner for all applications. 22% MANGANESE Optional fit for all Jaw & Cone crushers. Work hardens quicker in abrasive applications.

Learn Morejaw crushers liners

jaw crushers liners Jaw crusher parts JYS ADVANCED WEAR RESISTANT MATERIAL. R Crusher Wear Parts Reference Guide Liner wear in jaw crushers Request PDF Kenco Longer Wearlife Parts

Learn MoreResminer Jaw Crusher Liners - Wear Resistance Manufacturer in China

Resminer jaw crusher liners with the first-class quality of manganese steel have been verified in ISO quality standards. We produced our product using advanced machinery and technology that improves the efficiency of the production process. Resminer has the premium quality of jaw crusher liners made of the unique quality of manganese and alloy.

Learn MoreManganese Crusher Liners - Mining Wear Parts

Will manganese crusher liners optimise my crusher performance? Our aftermarket Manganese crusher liners for cone, jaw, gyratory, and impact crushers are cast

Learn MoreJaw Crusher Liner Plate Design & Profile Shapes

Jul 22, · Jaw Crusher Liner Plate Design & Profile Shapes. Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates. This type of

Learn MoreMill-Jaw crusher - MRC Lab

Laboratory Mill-Jaw crusher.Table instrument ○ Removable jaw for easy cleaning jaw plate and side liner should be ordered in pair. Table instrument ○

Learn MoreLaboratory Jaw Crusher - 911Metallurgist

The 911MPCJC200D Jaw Crusher is designed for batch-wise and continuous pre-crushing of middle hard, hard brittle, and tough materials for the following fine grinding. Quick and easy to clean due to front door access. Stepless, reproducible gap-setting by hand-wheel. Easy exchange of jaw plates and side liners.

Learn MoreCrusher Wear Parts Reference Guide - Corporation

The strength of a jaw liner is the ability to withstand crushing forces without failure, and is dependent on the metals microstructure. Manganese included in

Learn More

Leave A Reply