Polycorp - AG/SAG Mill Liners

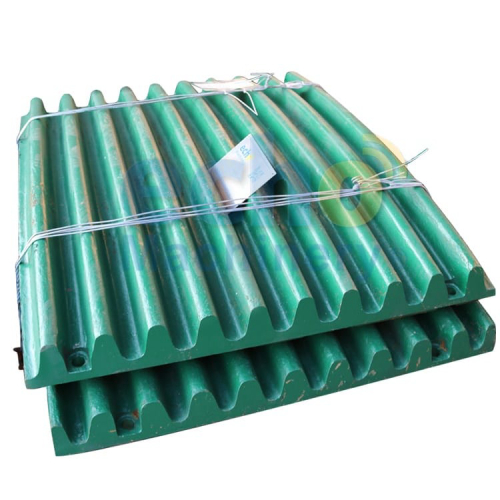

AG/SAG Mill Liners PolyStl™ Liners PolyStl™ liners are composites of a Special Wear Resistant Steel and High Pressure Moulded Rubber which are suitable for AG Mills, SAG Mills, Primary Mills and Ball Mills with ball diameters 3 ½ inches and larger. Learn more PolyBlok™ Liners

Learn More26' x 5.3' SAG Mill Liners - ME Elecmetal

SAG Mill. Full case in PDF. As a well-known globally competitive supplier, we can be ubiquitous. This success story led ME Elecmetal as far as Saudi Arabia, to help making a difference in our client’s copper operation. And we did: our customized grinding solution signi cantly increased SAG mill processed tonnage with no breakage at all, hence

Learn MoreSAG Mill Liners

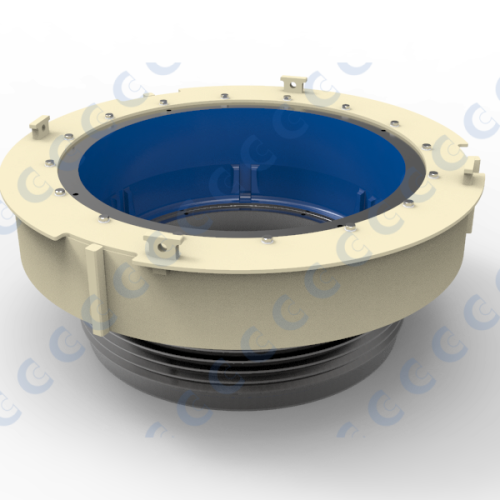

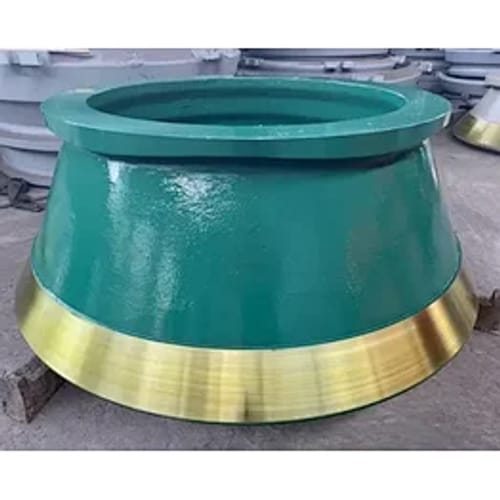

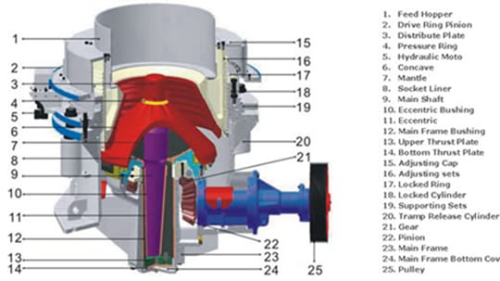

SAG Mill Liners include: feed head & discharge end as well as grates (both outer, middle and inner), pulp lifters (dischargers) shell lifter bars and plates.

Learn MorePDF Continuous improvement in SAG mill liner design using new technologiesPDF

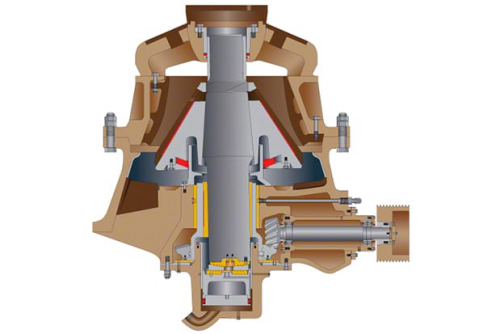

An industrial case study is presented of a 38' diameter SAG mill, which was experiencing challenges associated to liner breakage and low efficiency with the old liner design. Through a

Learn MoreMill liners: grinding out a legacy - Mining Technology

Typically, steel liners are used in aggressive AG/SAG Mill and ROD Mill applications, as rubber will not last on its own. Trelleborg does offer

Learn MoreMill Liners | Multotec

A broken liner, which is particularly severe for large AG/SAG mills, can arise from media impacting directly on the mill liner. Multotec's rubber mill linings are designed by combining the results of computer simulations and inspection data in order to optimise charge trajectory and wear life.

Learn MorePDF Semi-autogenous grinding (SAG) mill liner design and developmentPDF

with increasing mill speed as shell lifters wear, is a promising current development in shell liner design and SAG mill opera-tion providing the potential for lower energy consumption, increased throughput, and start-up "on-grind" with new lifters (Veloo et al., 2006b). Highly worn shell lifters can still deliver adequate (though

Learn MoreLinex Bed Liner in Hillsboro, OR with Reviews - YP.com

Find 4 listings related to Linex Bed Liner in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for Linex Bed Liner locations in Hillsboro, OR.

Learn MoreContinuous improvement in SAG mill liner design using new

An industrial case study is presented of a 38’ diameter SAG mill, which was experiencing challenges associated to liner breakage and low efficiency with the old liner design. Through a

Learn MoreThe design and evolution of SAG mill liner trails - Hatch

Development of SAG liners has always been of considerable interest to mill operators as liners significantly affect plant performance (throughput,

Learn MoreSAG Mill Distributor Archives - Page 4 of 4 - NCP International

NCP International supplies new and refurbished grinding mills, SAG mills, We supply competitively priced new mill liners, as well as new Chromoly and

Learn MoreSAG Mill liner set Ø38'x 27 - Aceros y Suministros

58m. x 8.22m.). The supply includes all the elements that make up the interior lining of the SAG mill: Feed end liners, Shell liners

Learn MoreAG/SAG Mill Liners - Polycorp

Polycorp PolyKombo™ Liners are a one piece liner with PolyStl™ lifters PolyStl™ rubber plates designed for use in SAG, AG or Ball mill applications. Learn more.

Learn MoreSAG Mill Grinding Circuit Design - Mineral Processing & Metallurgy

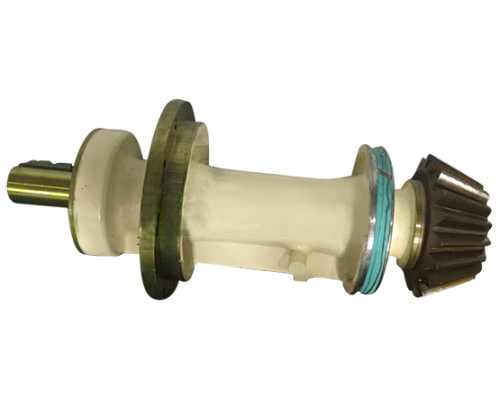

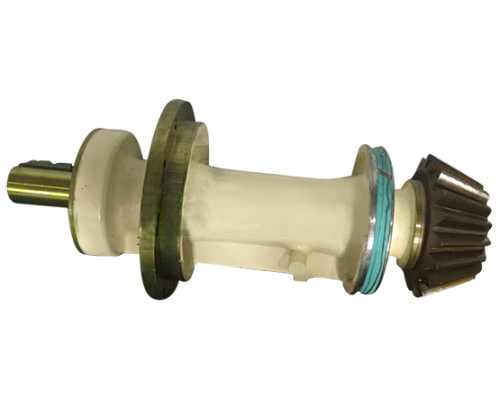

SAG Mill vs Ball Mill To a more significant degree than in other comminution devices, liner design and configuration can have a substantial effect on mill performance. In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity must be considered.

Learn MorePolycorp - Ball Mill Liners

These liners are custom designed for your mills. Mining Ball Mill Liners PolyStl™ Liners PolyStl™ liners are composite of Special Wear Resistant Steel and High Pressure Moulded Rubber which are suitable for AG Mills, SAG Mills, Primary Mills and Ball Mills with ball diameters 3 ½ inches and larger. Learn more PolyBlok™ Liners

Learn MoreVulco® Mill Lining Systems | Weir Group

The innovative designs of Vulco ® mill liners are tailored specifically for every customer and are manufactured to the highest industry standards for autogenous (AG) and semi-autogenous (SAG) mills, primary, secondary, and re-grind ball and rod mills. With an integrated approach, our skilled teams of engineers, designers and chemists consider

Learn MoreMill liners - Outotec

A mill lining is a customized wear part. Identifying the appropriate type of lining and design is vital for optimizing mill throughput and total grinding costs, including costs for energy, grinding media and maintenance. Furthermore, the design must be constantly optimized to meet your needs.

Learn MoreSag Mill Liners on sales of page 3 - Quality Sag Mill Liners supplier

Sag Mill Liners, You can Buy good quality Sag Mill Liners of page 3, we are Sag Mill Liners distributor & Sag Mill Liners manufacturer from China market. Sales & Support: Request A Quote. English English French German Italian Russian Spanish Portuguese Dutch Greek Japanese Korean Arabic Hindi Turkish

Learn MorePDF) Understanding the effects of liner we SAG mill

PDF | On Sep 7, , Paul Toor and others published Understanding the effects of liner we SAG mill performance | Find, read and cite

Learn MoreSAG and Ball Mill Liner - EB Castworld

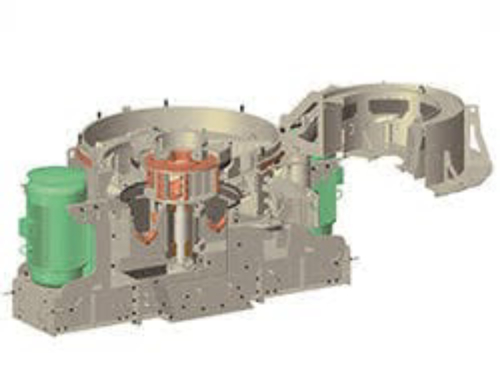

SAG and Ball Mill Linergrind material through different actions and are usually applied in different stages of the process. SAG mills usually have a larger diameter than length and are used to reduce large feed size ore (typically ~300mm) down to ~3mm, often for further grinding in a secondary process.

Learn MoreMegaliner™ mill liners - Outotec

Suitable for large AG, SAG and ball mills where uptime and safety are top priorities Outotec Megaliner™ concept reduces your downtime by minimizing the

Learn MoreLeaner and Meaner SAG Mills | Unicast Wear Parts

Among the new innovations that are improving the milling process is a condition monitoring technology that tracks SAG mill liners and

Learn MoreMine Mill Liners for SAG Mills And AG Mills DF038 As Per GB/T 26651

Mill Liners for sale, Quality Mine Mill Liners for SAG Mills And AG Mills DF038 As Per GB/T 26651- on sale of Zhengzhou Qianyue Mill Liners Co., Ltd. from China.

Learn MoreRubber - Growth Asia

In conventional Mill Lining Systems, Growth Rubber offers a full range of rubber liners for. SAG Mills; AG Mills; Primary & Secondary Ball Mills

Learn MoreSAG Mill Liner - EB Castworld

Dec 22, · SAG Mill Liner is used to improve the service life and grinding effect. The liner plates are fastened with oval head bolts, matched with self-locking nuts and sealing washers.The connecting bolts have special sealing measures to prevent leakage of slurry.

Learn MoreDischarge End Liner System - Bradken

Bradken is a leader in the design, manufacture and supply of mill and crusher liners for SAG/AG Mills, Rod Mills, Ball Mills in the global mineral processing

Learn MoreMill Liners for SAG Mills And AG Mills - EB Castworld % Mill Liner

Mill Liner Feature: 1.The Sag Mill Liners can be used in SAG mills and AG mills; 2.The steel castings have higher reliability in large mills. China mill liner supplier provides ball mill liner services to worldwide ball mill liners customer. Hope you find our mill liner process and grinding mill liners product description helpful.

Learn MoreWhat's the Difference Between SAG Mill and Ball Mill

The biggest characteristic of the sag mill is that the crushing ratio is large. The particle size of the materials to be ground is 300 ~ 400mm, sometimes even larger, and the minimum particle size of the materials to be discharged can reach 0.1 mm. The calculation shows that the crushing ratio can reach 3000 ~ 4000, while the ball mill's

Learn MoreSag Co LLC · 1979 Se 74th Ave, Hillsboro, OR 97123

SAG CO LLC (Registry# 187452496) is a business registered with Oregon Secretary of State, Corporation Division. The business registry date is September 27, 2021.

Learn MoreSAG mill liner selection to maximise productivity - Ausenco

With an increasing treatment of complex ore bodies with variable competencies, SAG mill liners and discharge systems are proving to be crucial components

Learn MoreMill liner solutions

options — mill liners offer industry leading wear protection for your SAG and ball mills. And, by incorporating unique geometric.

Learn More

Leave A Reply