Mill liner solutions

options — mill liners offer industry leading wear protection for your SAG and ball mills. And, by incorporating unique geometric designs

Learn MoreMetallic mill liners - Outotec

Outotec metallic mill linings are always designed with one thing in mind: to maximize performance and minimize replacement time. The solution offers total freedom of design and the possibility to optimize your lining based on operating data and liner handler capacity. Using linings of a modern design and maximized size minimizes the

Learn MoreAerofall Mill Liner Design

05/11/ · Aerofall Mill Application. According to the manufacturer, a distinctive feature of the Aerofall mill, as compared to the conventional mill, is the special feature of its wedge shape

Learn MoreSelection and design of mill liners - ResearchGate

An overview of the selection and design of mill liners was published by Powell et al (2006) , providing a reference source on mill liners,

Learn MoreThe effects of liner design upon charge motion in a rotary mill

The mill liner consists of thick blocks that are fastened to the be seen that liner design is not a straight forward matter,.

Learn MoreMill Liners for Ball Mills Increase grinding efficiency and

We design mill for raw mills we recommend heavy classifying liners. Your mill liner has a critical role to play in the performance of your ball mill

Learn MoreThe Selection and Design of Mill Liners - Zimaksan Co

The Selection and Design of Mill Liners Selection of the composition and type of materials for the production of liners is very important. Often, according to the type of application of the liners, the best materials for the construction of these liners should be selected, in order to obtain the maximum efficiency from them.

Learn MoreThe selection and design of mill liners

The selection and design of mill liners. Peter Radziszewski. Download Download PDF. Full PDF Package Download Full PDF Package. This Paper. A short summary of this paper. 37 Full PDFs related to this paper.

Learn MoreWellness By Design, Llc in Beaverton, OR - Medicare Clinic/Center

Wellness By Design, Llc is a medicare enrolled primary clinic (Clinic/center - Primary Care) in Beaverton, Oregon. The current practice location for Wellness By Design, Llc is 12725 Sw Millikan Way Ste 300, Beaverton, Oregon. For appointments, you can reach them via phone at (971) 998-9747.The mailing address for Wellness By Design, Llc is 1049 Sw Baseline St Ste D490, Hillsboro, Oregon and

Learn MoreLINNEA DESIGN HARDWARE - HILLSBORO, OR - Business Information

Search the business profile for LINNEA DESIGN HARDWARE in HILLSBORO, OR. Find other businesses with the D&B Business Directory at DandB.com. Products; Resources; My Account; Talk to a D&B Advisor 1-800-280-0780. Business Directory. OR. HILLSBORO. Hardware. Hardware.

Learn MoreMill Liner Design | Free webinar - Rocky DEM - ESSS

Recent advancements in Discrete Element Modeling (DEM) now enable engineers to simulate mill liner designs quickly and with a high degree of accuracy.

Learn MoreCement mill liners | Magotteaux

Design of cement mill liners There are several types of cement mill liners: feed-end-liners, lifting-liners, classifying liners.They all have some features in common. Magotteaux determines the optimum design and alloy for cement mill liners to give the best mill protection. This is done according to a variety of factors such as shell liner type, rotation speed, maximum ball

Learn MoreMill liners: grinding out a legacy - Mining Technology

25/04/2022 · Grinding out a legacy. Grinding mills play a key role in comminution and mineral dressing and are subjected to severe impact and abrasion from the Mineral being ground and

Learn MoreLow Alloy Steel Ball Mill Liners Design - Qiming Casting

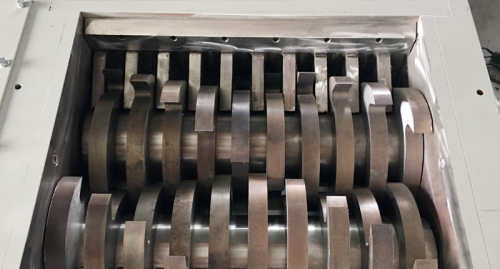

Low Alloy Steel Ball Mill Liners Design - Wear Parts For Industry | Qiming Casting The main function of the ball mill liner is to protect the mill and use the convex peak of the liner to play the ball to grind and crush the material. Therefore, the main failure mode of the liner is abrasive wear under the repeated impact of small energy.

Learn MoreA Review on Current Mill Liner Design and Performance

Milling management in Mining and Mineral Industries should keep on improving liner design based on operating experience, ore types, good design practice,

Learn MorePDF Semi-autogenous grinding (SAG) mill liner design and developmentPDF

For large mills, using 125 to 140 mm (5 to 5-1/2 in.) feed ball size, conventional new lifter-liner dimensions are around 300 to 350 mm (12 to 14 in.) overall height above the shell, with around 100 mm (4 in.) plate thickness and around 150 mm (6 in.) top width. Detailed design depends on individual mill circumstances.

Learn MorePDF] The selection and design of mill liners | Semantic Scholar

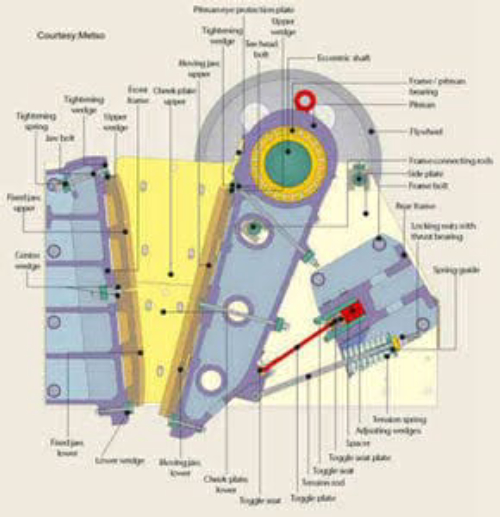

The selection and design of mill liners. M. Powell, I. Smit, +4 authors. L. Schaeffer. Published 2006. Materials Science. Dramatic shortcomings of mill liner designs, especially of large SAG mills, such as rapid failure and even mill shell damage arising from impacting of the charge directly on the liner, and unsuitable spacing of lifter bars

Learn MoreFive tips on mill liners to improve grinding profitability 1/2

19/08/ · Mill liner design in relation to total mill weight. Weight has a great impact on the process, so it needs to be considered in utilizing the maximum capacity of the grinding mill. The theoretical capacity is mainly based on volume of the mill, installed power and structural strength of the mill. The mill structure and bearings can handle a

Learn MoreMill lining solutions for horizontal mills - Outotec

design liners to fit your specific conditions. Improved safety through mill liner design, installation methods and modern tools.

Learn MoreContinuous Improvement in SAG mill liner design using new

This paper presents a methodology for continuous improvement of liner design, which uses information from the DEM collision energy spectra in the mill

Learn Moremill liner for sale, mill liner of Professional suppliers

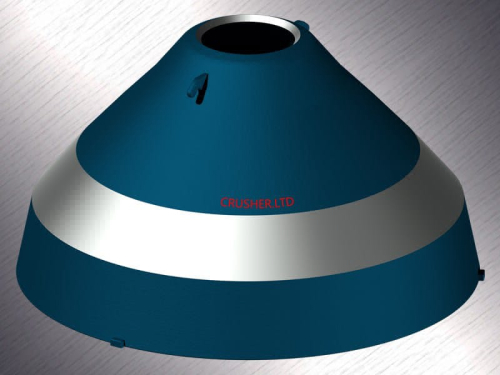

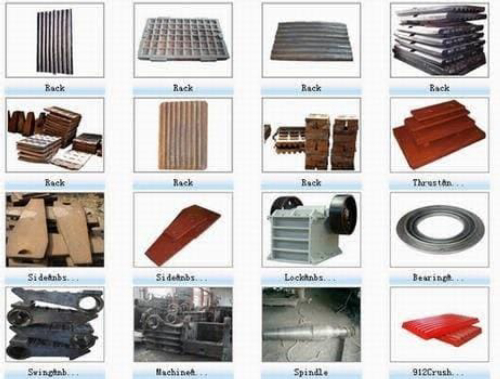

OHSAS18001 Mn18Cr2 Low Carbide Steel Grinding Ball Mill Liner Mill Shell Liner End Liner Grate Liner Grind Lining Product Description: Cast grinding ball mill liner, Mill liner plater, Ball Mill wearing plater, wear plate: A. Chrome Alloyed Ball Mill Liner Plates B. Chromium-Molybdenum Alloyed Ball Mill Liner Plates C. High Manganese Steel Ball

Learn MoreDecision Support Models for the Maintenance and Design of

The rubber liners inside the mill are critical components for mill shell protection and ore grinding. The replacement and inspection of mill liners are major

Learn MoreBall Mill Liners Selection and Design | Ball Mill Rubber Liner

Function Design of Ball Mill Liners As one of professional ball mill liners manufacturers, we summarize the main functions of the three-point ball mill liners. It mainly involves the protection of the barrel and the control of the grinding medium. Protect the ball mill barrel and enhance the rigidity of the barrel

Learn MoreMill Liner Market Strategies, Geographical Analysis And Fore

The global Mill Liner market is valued at 2493 million US$ in is expected to reach 3497.6 million US$ by the end of 2026, growing at a CAGR of 4.9% during 2021-2026. Global Mill Liner Market

Learn MorePDF The Selection and Design of Mill LinersPDF

Figure 5. High-low wave ball mill liner Materials The selection of the material of construction is a function of the application, abrasivity of ore, size of mill, corrosion environment, size of balls, mill speed, etc. liner design and material of construction are integral and cannot be chosen in isolation.

Learn MoreMill Liners - Multotec

Careful balance is needed to optimise these differing requirements, as poor liner design has detrimental effects on milling performance – and on mill liner

Learn MoreBrunswick Mine SAG Mill Liner Design and Wear

01/01/2003 · The “Mill Redesign Project” at INCO’s Clarabelle Mill Design, Construction, and Start-up of Stillwater Mining’s Ea Grinding Circuit Improvements at Barrick Goldstrike’s Roaste Brunswick Mine SAG Mill Liner Design and Wear The use

Learn MoreSAG MILL LINER DESIGN FOR SECONDARY CRUSHING

SAG MILL LINER DESIGN FOR SECONDARY CRUSHING. 2012. SAG MILL LINER DESIGN FOR SECONDARY CRUSHING. Keywords: Mill liners;Grates;SAG Mills.

Learn MoreThe Selection and Design of Mill Liners - MillTraj

Mill Linings Systems/Technical Support, Minerals, , SE-934 81 Ersmark, Sweden ٭ Mill linings, Weir Rubber Engineering, Salt Lake City, UT 84126, United States of America .

Learn MoreKey considerations when selecting a mill lining system - The Weir Group

Key considerations. Numerous factors must be considered when selecting a mill liner design, including required grinding action, mill size as well as ore and grinding media characteristics, among others. These considerations will help determine the best liner material and geometry. Depending on the mill size and material being ground, a lining

Learn MoreThe effects of lifter configurations and mill speeds on the mill

materials, which are utilized for mill liners and grinding balls. Both liner design and mill speed can bring ball trajectories to directly go towards

Learn More

Leave A Reply