Ball Mills - Mt Baker Mining and Metals

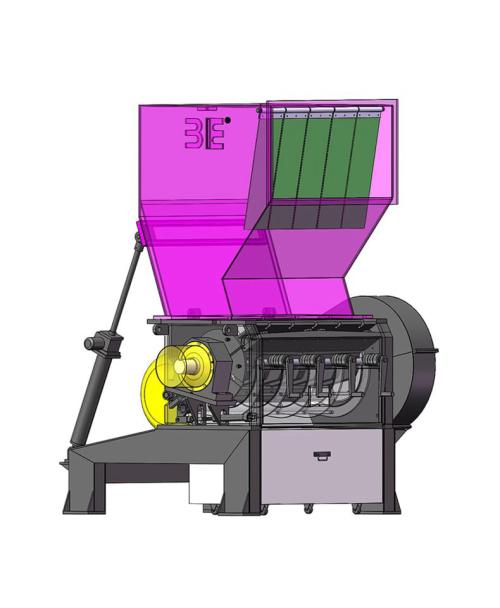

Ball Mills. Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling is justified by an operation. Sold individually or as part of our turn-key

Learn MoreWholesale Jaw Mill Manufacturer and Supplier, Factory Pricelist

Jaw Mill; Jaw Mill - Manufacturers, Factory, Suppliers from China. Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members.

Learn MoreWear Parts For Pioneer Jaw Crusher

For replacement jaw crusher wear parts, click HERE . Hewitt Robins Grizzly King 42X48, Pioneer 18X30, Austin Western 12X36, Pioneer 10X36 jaw crusher.

Learn MoreBoring Mills Jaws | Kitagawa

BM Series Boring Mill Jaws. Cookie. Duration. Description. cookielawinfo-checbox-analytics. 11 months. This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the

Learn MoreRetsch Jaw Crusher BB 100, 14.592,00

Retsch Jaw Crusher BB 100. ProfiLab24.com laboratory supplies and laboratory equipment with top advice and 24H serviceRET_12002.

Learn MoreMill Workholding - Workholding - Tooling - Tormach

Mill Workholding; Mill Workholding. Mill Workholding. Featured Products . Showing 1-48 of 75 items 6 in. TalonGrip™ Vise Jaw Systems - Mitee-Bite - Compatible with Tormach 4 in. and 5 in. vises . PN: 51253. Add to Cart. $59.95. CarveSmart 1018 Steel Jaw Set with SmartStop 3/4in. x 2in. x 4.5in. - 2pk

Learn MoreJaw Crushers - high quality and reliability from RETSCH

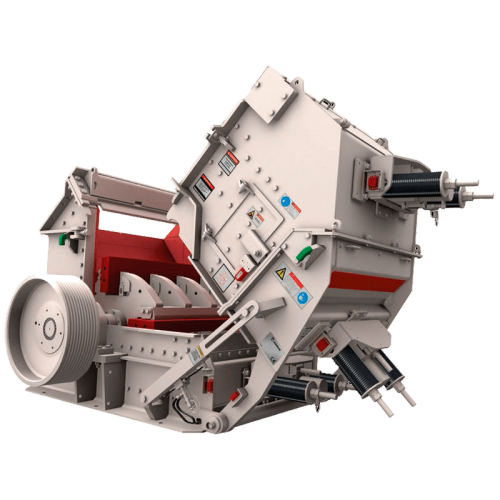

The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard, brittle and tough materials.

Learn MoreHow Does a Jaw Crusher Work - Kemper Equipment

A jaw crusher is an important piece of machinery that helps break aggregate material down into the right size. Learn more about this machine on our blog

Learn MoreStellar stone jaw mill For Construction

The prime stone jaw mill options take productivity a step higher. The stone jaw mill choices have innovative designs for sand processing efficacy.

Learn MoreC150™ jaw crusher - Outotec

C150™ jaw crusher is an effective jaw crusher in the 50-ton (112 000 lbs) weight class. It has been developed for the most demanding large-scale

Learn MoreJaw Crushers | Glen Mills, Inc

The Jaw Crusher BB 300 is used for the rapid, effective crushing and pre-crushing of medium-hard, hard, brittle and tough materials. Its variety of materials offered, including heavy-metal free steel and its efficiency and safety makes the BB 300 ideal for sample preparation in laboratories and industrial plants.

Learn MoreTrio® CT Series Jaw Crushers - The Weir Group

The Trio® CT Series jaw crusher is a robust comminution machine with innovative features that make it the clear choice for primary crushing applications within

Learn MoreThree-Jaw Chucks | McMaster-Carr

Hex-Shank Keyed Drill Chucks forPower Screwdrivers and Impact Drivers. Convert a power screwdriver or impact driver into a versatile drill. Also known as adapt-a- drive, these chucks have a 1/4" hex shank that fits the hex drive in most power screwdrivers and impact drivers.

Learn Morehow a jaw crusher works and what it is used for

A Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant. The size of a jaw crusher is designated by the rectangular or

Learn MoreCompact Jaw Crusher at Affordable Deals

Keep the construction job rolling smoothly using a sturdy jaw crusher. Achieve high efficiency and productivity with these crushers available on

Learn MoreJaw Muscle Soreness treatment near Hillsboro, OR

Find top doctors who treat Jaw Muscle Soreness near you in Hillsboro, OR. Book an appointment today!

Learn Morejaw mill | buy cone crusher spare wearing plate

jaw mill. Vise Comparison. One significant differentiator between vises is the mechanism that holds the movable jaw down as the vise is tightened. If the movable jaw has a tendency to lift as the vise is closed, it can be hard to keep the work piece firmly down on the parallels in the vise.

Learn MoreJaw Crusher Working Principle - 911 Metallurgist

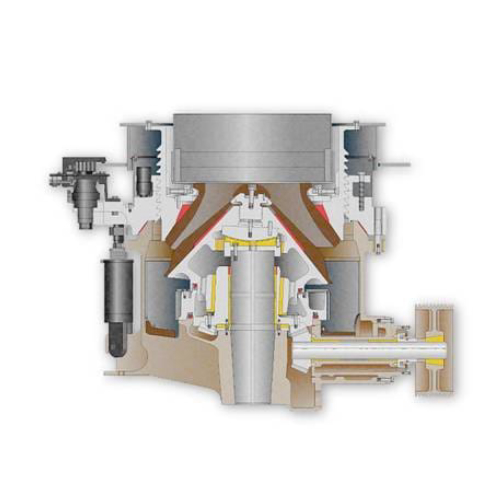

The single-toggle type jaw crusher has been developed extensively. Because of its simplicity, lightweight, moderate cost, and good capacity, it

Learn MoreLaboratory and pilot plant Primary Jaw Crushers

The Essa JC1000 Jaw Crusher is the smallest of the range. It is a medium-duty, entry-level machine designed for crushing smaller samples across a wide range of

Learn MoreLiberty Jaw Crusher | Primary Compression Crusher

If you can explain how a nutcracker works you can essentially envision the operation of a Liberty Jaw Crusher. Inside the chamber there are two jaws. One is

Learn MoreJaw Crushers | Heavy Duty | Finlay

The Finlay® J-1160 mobile jaw crusher is a primary crusher for aggregates production as well as concrete and asphalt recycling applications. The machine has

Learn MoreJaw Crusher,Ball Mill,Mining Crusher,Mining Equipment

Henan Ascend Machinery & Equipment Co., Ltd. was established in 2005 and it is located in the high-tech zone of Zhengzhou City, Henan Province. As a technology driven Mining Equipment

Learn MoreCrushers, Pulverizers & Mills - Gilson Co.

Crushers include offers jaw crushers, hammermills, cone crushers, and roll crusher options, each with multiple models, and designed for performance on harder materials such as ores, minerals, coal, and rock. Pulverizers efficiently reduce aggregate, mineral or coal sample particle sizes using grinding plates, hammermills, or centrifugal impact.

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

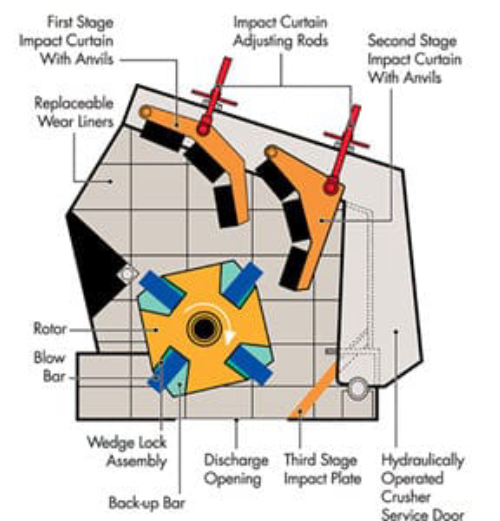

All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement of

Learn MoreJaw Crusher - an overview | ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is

Learn Morejaw mill | 7Ft part Outer Eccentric Bushing

unit of jaw hamer mill warking. Jaw Crushers and Hammer Mills for Ore Mining Our jaw crushers, hammer mills, and shaker tables Hammer mill is a economical unit designed for general ail-round work for time saving operation Most LT125 SW M22-WRK3 / AK40 7 ft crusher 44 fc parts GP11F PARALLEL KEY DIN6885-D18X11X63 jaw

Learn MoreJaw Concepts | Beaverton OR | Read Reviews + Get a Free Bid - BuildZoom

Jaw Concepts Llc holds a $1,000,000 insurance policy with Ohio Security Insurance Company. Financial recourse when hiring Jaw Concepts Llc Licensed contractors in Oregon are required to carry a surety bond (ranging from $10k up to $75k based on their trade), which provides you with financial recourse in case they perform defective work or

Learn Morejaw mill | universal flow monitors distributors

Jaw Mill; Jaw Mill - China Manufacturers, Factory, Suppliers Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers' needs for Jaw Mill, Jaw Crusher Alibaba, Micro Jaw Crusher, Small Sand Maker,Aggregate.

Learn MoreUsed Jaw Mill for sale. Bullard equipment & more

63" 4 Jaw Chuck C Axis Chuck Rotation Mill ing Capability Coolant Through the RAM Chip Conveyor Adjustable Cross Rail 18 Station Tool Changer - (9) Mill ing / (9) Turning RS 232

Learn Morejaw mill | spare shaft sleeve for ceramic pepper mills

Boring mill jaw. DV/DN. Vertical and vertical horizontal stationary power chuck. 1. Suitable for vertical milling and drilling operations. Directoy of jaw mill manufacturers, exporters, importers. Ball Mill (std.) [Ahmedabad] This Ball Mill is a very sturdy attachment and mainly used for grinding crystalline materials and for the mixing of dry

Learn MoreJaw Crusher Explained - saVRee

How Jaw Crushers Work. A jaw crusher uses compressive force for breaking ore pieces. Compressive force is applied by two jaws (dies), one of the crusher jaws is

Learn More

Leave A Reply