Heat exchanger network retrofit with heat exchanger and material type selection

3/1 · In this section, features of different HE types are discussed to provide insight into the selection of a HE type. 2.1.1. Double pipe heat exchanger A Double Pipe Heat Exchanger (DPHE) is equipped with two concentric circular pipes. The inner and outer pipes have different diameters, and the inner tube pass and the annulus pass are flow regions.

Learn MorePDF Selecting Reliable Heat Exchanger Tube Materials - Factors to ConsiderPDF

Selecting Reliable Heat Exchanger Tube Materials - Factors to Consider PRESENTED AT: API Power Chem Novotel Twin Waters, Sunshine Coast, Queensland May 27, Presented by: Daniel S. Janikowski Technical Manager Plymouth Tube Company 2061 Young Street East Troy, WI 53120, USA Phone +1 262-642-8365 [email protected]

Learn MoreHeat Exchanger Tube Material Selection

For one of our AES type heat exchanger, we noticed leakage in the tubes so please advise me which material is suitable for highly corrosive

Learn MoreHeat Exchanger Tu Manufacturer - Tube Heat Exchanger - Plymouth Tube

They can help you select the best material for your application at the lowest cost. And if there's an ever an issue after installation, we can be on-site within 3 business days worldwide. PRODUCT OFFERING Welded Stainless Steel Tu Seamless Stainless Steel Tu Feedwater Heater Tu Condenser Tu Welded Stainless Steel Tu

Learn MorePDF) Material selection and design of shell and tube heat

The heat exchanger is made of acrylic material with 2 baffles and 7 tubes made of stainless steel. Hot fluid flows inside the tube and cold

Learn Moreheat exchanger tube material selection for sale, heat exchanger tube

Heat-exchanger tube Seamless Stainless Steel Tube,selected prime raw material,cold drawn, clean and smooth surface on OD/ID,Withstand high pressure,no deformation after cold bending, no crack and break after flattening and flaring etc. Widely used in the following fields: Boiler and heat-exchanger Heater and condenser Delivery Condition: Bright

Learn MoreSelecting Tu Materials for Power Generation Heat

Selecting Tu Materials for Power Generation Heat Exchangers Presented at the Power-Gen International Conference at New Orleans, Dec 12, 2007 Daniel S. Janikowski Corporate

Learn MoreHeat Exchanger Type Selection - H&C Heat Transfer

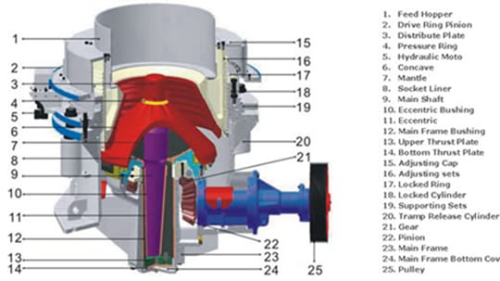

Mechanical considerations such as: 1) material of construction; 2) thermal stresses (during startup, shutdown; process upset and clean out conditions); 3) impingement protection Shell-and-tube heat exchangers accounts for more than 50% of all heat exchangers installed.

Learn MoreSelection of Shell & Tube Heat Exchangers | TEMA Types Comparisons

i) Straight Tube, Fixed tubesheet, Type BEM, AEM, NEN, Etc. This TEMA type is the simplest design and is constructed without packed or gasketed joints on the shell side. The tubesheet is welded to the shell and the heads are bolted to the tubesheet. On the NEN heat exchanger, the shell and the head is welded to the tubesheet.

Learn MoreTU MATERIAL SELECTION FOR NUCLEAR POWER

In the previous times aluminum, brass and after that the wide variety of stainless steel choices available (ASTM lists over 75 alloys) gives the Heat. Exchanger

Learn MoreBrass & Copper Tube Selection Guide - Chicago Tube & Iron

BRASS AND COPPER TUBE SELECTION GUIDE 2.1 INTRODUCTION Condenser and Heat Exchanger Tubes are required to transfer heat in a wide variety of operating conditions and to resist corrosion for the longest period of time possible. Operating conditions may cover temperature ranges from sub zero to 1000F, fluid velocities from 1-15 feet per second and []

Learn MoreThe Role Stainless Steel in Industrial Heat Exchangers

Seamless & welded tu for shell-and-tube exchangers as starting points for material selection for heat exchangers. In certain.

Learn MorePDF Selection of Materials for Heat ExchangersPDF

2.0 GENERAL CRITERIA FOR MATERIALS SELECTION The engineer making the materials selection must know all the aspects involved in the construction, operation and maintenance of the heat exchanger. The importance of this is illustrated with the following examples: an operator may isolate a heat exchanger with raw water for sufficient time to

Learn MoreGeneral Criteria for material selection of Heat Exchangers - UES

5/20 · The heat exchanger designer would also identify the tube attachment method as this also affects the material selection is being done by someone other than the heat exchange designer, there must be close consultation between these individuals.

Learn MoreAnalysis of Shell and Tube Heat Exchanger Materials - IRJET

exchange of heat between two fluids. A power plant chemist/engineer has many choices when selecting tu materials for heat exchanger. Most industrial.

Learn MoreHow to Select the Correct Heat Exchanger Tube Plug - Torq N' Seal

For more information, please visit WWW.TORQ-N-SEAL.COM, email [email protected], or call 1 (201) 641-2130. Use our Plug Selector to find the right solution for your leaking heat exchangers and place a request for quote. Click Here for Plug Selector.

Learn MorePDF Heat Exchanger Materials - upmet.comPDF

2205, Stainless Steel 304/304L, 316/316L, and Nickel Alloy 625 commonly used in air-cooled heat exchangers is available on our website www.upmet.com. A plate heat exchanger is a specialized design well suited for the transfer of heat between medium and low-pressure fluids.

Learn MoreNumerical: Material selection for Heat exchanger

In this lecture, a numerical problem has been solved to maximise heat flow per unit area for a heat exchanger using the Ashby approach.

Learn MoreTu material selection for nuclear power plant heat exchangers

Tu material selection for nuclear power plant heat exchangers, Authors: Sa Anandan, Noorul Islam University, R. Rajesh, Abstract, A Nuclear power plant has many choices when selecting tubing

Learn MoreFactors Affecting Selection of Tubes of Heat Exchanger

The best and most suitable tube material and sheet as well as fluid optimum speed in the tube or converters shell can be selected through information presented

Learn MoreMaterial selection and design of shell and tube heat

Here shell and tube type heat exchanger has been selected due to its flexibility of design, which allows wide range of pressures and temperatures. Standards

Learn Moretube heat exchanger material selection - Large-scale Pressure

tube heat exchanger material selection, Heat Exchanger Tubes are used in Shell and Tube Heat Exchanger with all types of process industries.such as chemical processing, hydro carbon processing and oil refining, nuclear power generation and aerospace

Learn MoreSelection of Shell and tube heat exchanger (STHE) - SlideShare

Floating head Split ring (S type), Pull through (T type), Externally sealed tubesheet (W Type) and Outside packed (P Type) Type S and Type T are the common types of Floating head Floating head type or U-tube type heat exchanger should be selected if flexibility is required to avoid overstressing.

Learn MoreComparison of Materials Choices for Heat Exchanger Tubes

10/26 · In fact, there are more than 75 stainless steel alloys and more than 400 copper alloys, according to ASTM. When expanding to a further array of materials such as titanium, nickel, ferrous and non-ferrous alloys, graphite, glass

Learn MoreAlternatives to Copper & Aluminum for Heat Exchangers

Alternatives to Copper & Aluminum for Heat Exchangers · Stainless steel and stainless super alloys · Carbon steel · Titanium.

Learn MoreHow much chloride?: Power Plant Heat Exchanger Materials Selection - Power Engineering

10/10 · Time and again, the authors have reviewed new power project specifications in which the plant designers routinely select 304 or 316 stainless steel as the tube material for condensers and auxiliary

Learn MoreSelection of materials for heat exchangers - Heanjia Super Metals Co. Ltd

Main factors that influence material selection are: High heat transfer coefficient Low coefficient of thermal expansion and fit with the materials used in tubesheet, tube support and shell to resist thermal cycling. Good tensile and creep characteristics Good fatigue and corrosion fatigue and creep-fatigue behavior

Learn MoreHeat exchanger selector tool | Alfa Laval

HEXpert - The heat exchanger selector tool. Alfa Laval HEXpert makes it quicker than ever to get the product and application knowledge you need to find your ideal heat exchanger. Just answer a few short questions and get a customized recommendation to meet your unique needs. The tool currently covers products for design pressures up to 100 bar

Learn MoreMaterial selection for shell and tube heat ... - AIP Publishing

Material Selection for Shell and Tube Heat Exchanger Using. Computational Fluid Dynamics Method. Rosyida Permatasari1, a) and Adhi Muhammad Yusuf1, b).

Learn MoreSelection of materials for heat exchangers - Heanjia

The recommended materials of construction for steam generator tu are: Heat treated Inconel 600 wire Incoloy 800 Monel 400 Stainless steel 304 Stainless steel 316/316L Major tube

Learn MorePDF Selecting Tu Materials for Power Generation Heat ExchangersPDF

corrosion may be a cost-effective design option. Heat exchanger designers commonly add a "corrosion allowance" to a high-pressure carbon steel feedwater heater to allow for a 10 to 25 year lifetime. Copper alloys are often chosen for condensing and BOP heat exchangers, and 25-year lifetimes are not uncommon.

Learn More

Leave A Reply