Henkel Loctite | 1694859 | LOCTITE PC 9020 5GAEN | Applied

Shop Henkel Loctite 1694859 at Applied.com, which includes; Loctite® PC 9020™ Nordbak® Backing Compound, 100% Solids Epoxy Compound For Use In Water Flush Systems, Provides Highest Compressive Strength And Impact Resistance.

Learn MoreSG6275 BACKING COMPOUND 9505 9901, NORDBAK STA | that department is the

Jun 18, · 1095059901 backing compound 9505 9901, nordbak sta sg6275 10.000: 1095059940 backing compound k-241-22, 2.2 gallon p mp1000 10.970: 1095059944 backing hi-performance, wf ultra 5gal bk z036 9.980: 1095059960 locking agent 9505 9960 (2.8 kg) hp700 3.600: 2000742383 tube b10 1.100: 7000009295 spring cvb2050 8.300: 700010 spring

Learn MoreSG6275 BACKING COMPOUND 9505 9901, NORDBAK STA

1095059901 backing compound 9505 9901, nordbak sta sg6275 10.000 1095059940 backing compound k-241-22, 2.2 gallon p mp1000 10.970 1095059944 backing hi-performance, wf ultra 5gal bk z036 9.980 1095059960 locking agent 9505 9960 (2.8 kg) hp700 3.600 2000742383 tube b10 1.100 hanaのディズニーとおでかけ:2021年05月

Learn MoreLoctite 1694859 - Motion

PC 9020™ Nordbak® Backing Compound . LIST PRICE $369.28 each. Register for your price . IN STOCK . SHIPPING . In stock . Get Expected Arrival Date . Enter Postal Code. DOT Ship Hazard. Note: Delivery time estimates are based on real-time product availability and standard ground shipping.

Learn MoreLoctite PC 9020 Nordbak Backing Compound LDS - Scribd

Loctite PC 9020 Nordbak Backing Compound LDS - Free download as PDF File (.pdf), Text File (.txt) or read online for free.

Learn MoreFacilities & Rentals | City of Hillsboro, OR

Community & Recreation Centers. With several facilities in the Hillsboro Parks & Recreation Department, there is something for everyone. Stretch your creative juices at the Walters Cultural Arts Center, then stretch your body in one of our fitness areas. Enjoy nature at Jackson Bottom, then cheer on your favorite team at a sports complex. Join us!

Learn MoreSG6275 BACKING COMPOUND 9505 9901, NORDBAK STA | 1769-if2of2

Jun 18, · 1095059901 backing compound 9505 9901, nordbak sta sg6275 10.000: 1095059940 backing compound k-241-22, 2.2 gallon p mp1000 10.970: 1095059944 backing hi-performance, wf ultra 5gal bk z036 9.980: 1095059960 locking agent 9505 9960 (2.8 kg) hp700 3.600: 2000742383 tube b10 1.100: 7000009295 spring cvb2050 8.300: 700010 spring

Learn MoreLOCTITE PC 9020 Nordbak Backing Compound

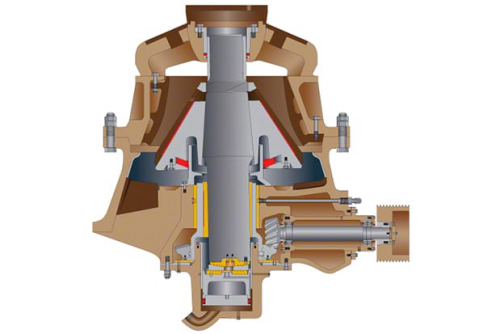

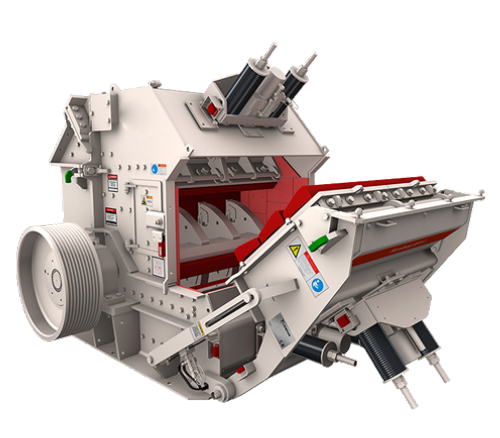

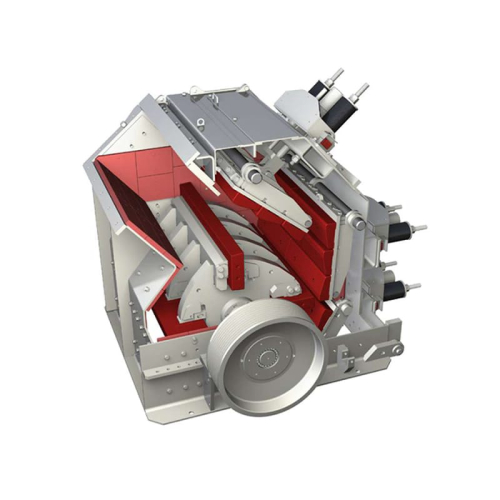

LOCTITE PC 9020 Nordbak Backing Compound is an epoxy system for backing wear metal in gyratory and cone crushers under typical dry service temperatures of

Learn MoreProduct Description Sheet Nordbak High Impact Wearing

LOCTITE ® Nordbak ® High Impact Wearing Compound is a two-component, rubber modified epoxy that offers the wear resistance properties of an epoxy along with impact resistance not usually found in epoxy formulations. With impact resistance superior to ceramic tile, High Impact Wearing Compound is recommended for lining and protecting flumes,

Learn MoreLOCTITE PC 9020 Nordbak Backing Compound Update - Motion Industries

LOCTITE PC 9020 Nordbak Backing Compound Update - Motion Industries

Learn MorePDF Henkel - Your worldwide partner Products at Work In Mines ... - KraydenPDF

zinc backing Loctite ®Nordbak® Backing Material A 100% solids epoxy compound, Loctite ®Nordbak Backing Material is formulated for backing wear plates in cone crushers and grinding mills operating under normal conditions. Features include: • High compressive strength and impact resistance • High volumetric stability to eliminate gaps

Learn MoreLOCTITE PC 9020 - North America - Henkel Adhesives

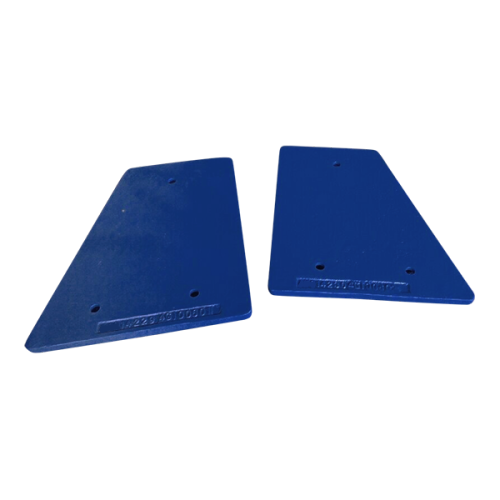

LOCTITE® PC 9020 (known as NORTH AMERICA - NORDBAK HP CRUSHER BACKING) is a blue, 2-part epoxy system for backing wear metal in gyratory and cone crushers under typical

Learn MoreLoctite 408041 - PC 9462 Crusher Backing Compound - 10kg

Features 100% Solid epoxies system for backing wear metal in crushers and grinding mills Temperature range: -28°C to +104°C Applications Suitable for

Learn MorePDF LOCTITE Nordbak Crusher Backing Materials - Kaman Industrial TechnologiesPDF

LOCTITE®Nordbak Backing Material • 100% solids epoxy compound for backing wear plates in cone crushers and grinding mills • Provides high compressive strength and impact resistance • High volumetric stability eliminates gaps between liners • Nonflammable • Pourable compound requires no melting or special equipment LOCTITE®Nordbak®Trowel Mix

Learn MoreMining: The Ultimate Wear Coating Stress Test - JE-Bearing

Epoxy backing systems such as Loctite PC 9020™ Nordbak Backing Compound are used between the liners and crushing plates of rock crushers,

Learn MoreLOCTITE PC 9462 - Crusher repair product - Henkel Adhesives

LOCTITE Nordbak Backing Material is a 2-part liquid epoxy compound for backing wear plates in cone crushers and grinding mills. LOCTITE® PC 9462 is a blueish-green to dark grey, 2-part,

Learn MoreSG6275 BACKING COMPOUND 9505 9901, NORDBAK STA 1769-crl3 datasheet

SG6275 BACKING COMPOUND 9505 9901, NORDBAK STA 1769 iq16 wiring BOGVIK Customized Impact Plate - Богвик Дейли. May 18, · 1095059901 backing compound 9505 9901, nordbak sta sg6275 10.000: 1095059940 backing compound k-241-22, 2.2 gallon p mp1000 10.970: 1095059944 backing hi-performance, wf ultra 5gal bk z036 9.980: 1095059960 locking agent 9505 9960 (2.8 kg) hp700 3.600

Learn MoreMarch-2006 - Henkel

LOCTITE® Nordbak® Backing Material is the original 100 % solids epoxy system for backing wear metal in crushers and grinding mills. The product needs no melting or special equipment, has high volumetric stability that eliminates formation of gaps between backing and liners or support structures, and contains elastomers for high impact and shock

Learn MoreMATERIAL SAFETY DATA SHEET - myhenkel.asia - FlipHTML5

NORDBAK BACKING RESIN is used in conjunction with LOCTITE PC 9406. PROPORTIONInorganic calcium compound [25068-38-6] 60-80%

Learn MoreLoctite Nordbak 9020 5 Ga Es - Logfer

LOCTITE PC 9020 A/B. Backing Compound 23,01kg. conhecido como NORDBAK Backing Compound , é um sistema epóxi de duas partes para suporte de metal desgastado.

Learn MoreLOCTITE Nordbak Backing Material - Henkel

LOCTITE® Nordbak® Backing Material provides the following product characteristics: Technology compound. Do Not use open flame on compound.

Learn MoreNordbak Standard Backing Compound. Koni̇k Kirici Yastiklama İlaci

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features Press Copyright Contact us Creators

Learn MoreLoctite PC 9020 Nordbak Backing Compound Como mezclar

Loctite PC 9020 es un compuesto antidesgaste especialmente usado para maquinas trituradoras de piedras y agregados. Forma una capa protectora a las maquinas

Learn MoreLOCTITE Nordbak Wearing Compound™ - The Wercs

LOCTITE® Nordbak® Wearing Compound™ is a ceramic bead filled two-part epoxy putty, designed to protect equipment from coarse particle abrasion in wet and dry service. Typical

Learn MoreNordbak Backing Compound 53Lbs - La Casa del Perno

Nordbak Backing Compound 53Lbs. $522.54. Cantidad. Agregar al carrito. Agregar al carrito. Copyright © La Casa del Perno - Todos los derechos

Learn MoreTechnical Data Sheet Nordbak High Impact Backing Material - The Wercs

LOCTITE®Nordbak®High Impact Backing Material must be at 15 °C to 26 °C before use. Lower temperatures give longer working life, but higher viscosity (harder to pour), while higher temperatures reduces working time to pour into crusher. Mixing: 1. Pre-mix resin approximately 1 minute. 2. Shake hardener thoroughly mixing its contents. 3.

Learn MoreSG6275 BACKING COMPOUND 9505 9901, NORDBAK STA | cone crusher parts

CRUSHER BACKING Nordbak. 9505 9901 (10 kg) 9505 9905 (20 kg) STANDARD BACKING NORDBAK® STANDARD BACKING is a tough, resilient and ideal backing for smaller Cone Crushers, Gyratory Crushers, Rotating Mills, Pulverisers and other heavy reduction machinery.Loctite® PC 9020™ Nordbak® Backing Compound Superior Performance, Low

Learn MoreNordbak - Crusher Backing

NORDBAK® LOW VISCOSITY BACKING is a low viscosity backing that is tough, resilient and ideal for pouring into small orifices of smaller Cone Crushers, Gyratory Crushers, Rotating Mills, Pulverisers and other heavy reduction machinery. 9505 9960 (2.8 kg) LOCKING COMPOUND. NORDBAK® LOCKING COMPOUND is a high temperature and high impact material

Learn MoreLOCTITE PC 9020 NORDBAK HP CRUSHER BACKING 10KG - Maith Gulf

known as NORTH AMERICA - NORDBAK HP CRUSHER BACKING, is a 2-part epoxy system for backing wear metal. LOCTITE® PC 9020 (known as NORTH AMERICA - NORDBAK HP CRUSHER BACKING) is a blue, 2-part epoxy system for backing wear metal in gyratory and cone crushers under typical dry service temperatures of -20 °F to +220 °F (-30 °C to +105 °C).

Learn MoreGyratory crusher backing compound - Crushing, Screening

Hi. What is the best type of backing compound to use between the mantle and the main shaft in a gyratory crusher? Is it an epoxic base material?

Learn MoreLoctite Industrial on Twitter: "Loctite PC 9020 Nordbak

Loctite PC 9020 Nordbak Backing Compound can replace several other products! http://go.clickmeter.com/afan/ #newproduct.

Learn More

Leave A Reply