SAG mill wear optimization using DEM simulation - Rocky DEM

In the case of semi-autogenous (SAG) mills, these losses can be excessive. SAG mills are the technology of choice for reducing primary hard-rock

Learn MorePDF EXPERIENCES IN SAG MILL OPERATION - intermetperu.comPDF

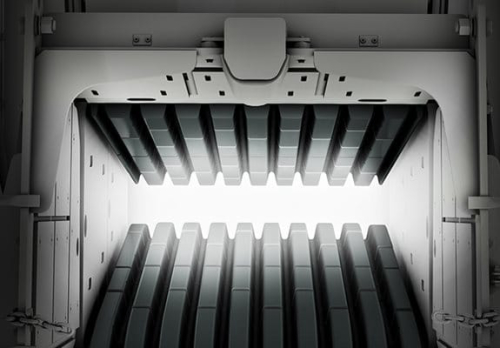

Describe in detail SAG mill circuits of large-scale plants and the benefits of each. - Detail the issues occurred during SAG mill operation: blockage of grates, cracking of bolts, liners and grates, flowback, carry over; blockage and breakage of meshes from trommel and screen, among other relevant issues.

Learn MoreOperation Of Sag Mill

operation of SAG mills. SAG mills are currently the technology of choice in hard rock milling operations for reducing primary-crushed ore to ball mill feed. In recent years, the trend has been towards larger-sized SAG mills with diameters of 10.4 m 34 ft and above, with the largest being 12.2 m 40 ft in

Learn MoreSossego Sag Mill: 10 Years of Operation and Optimizations

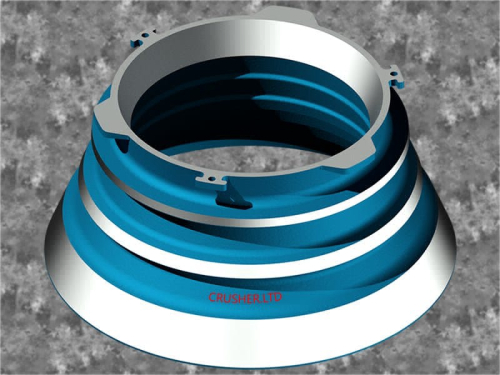

A number of optimization and upgrading measures were taken over the 10 years of operation of the semi-autogenous mill, including changes in the grate area, size and arrangement of aperture, liner

Learn MoreCONTROL AND OPERATION OF SAG MILL - PEBBLE CRUSHING CIRCUITS

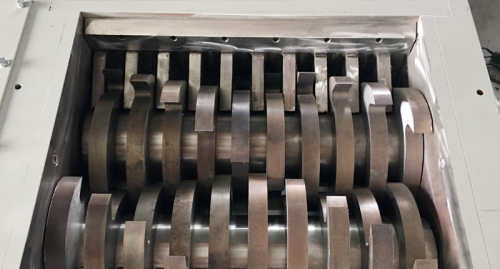

SAG mill operation Feed preparation - putting particles in the wrong sizes during crushing Discussion on Feed Preparation Principles of Crusher operation Discussion on the purpose and needs of process control Process control, Lag time for feed rate and load interaction, grindcurves Controlling the Dynamic Behaviour of the Mill

Learn MorePDF OPTIMAL SAG MILL CONTROL USING VIBRATION ... - Digital Control LabPDF

OPTIMAL SAG MILL CONTROL USING VIBRATION & DIGITAL SIGNAL PROCESSING TECHNIQUES *Karl S. Gugel, Ph.D. Digital Control Lab, 4647 NW 6th St. point every two hours or more is more common and allows for one to ensure stable mill operation for an extended period of time. The optimal set point should therefore be determined from the other process

Learn MoreMill (grinding) - Wikipedia

The grinding of solid materials occurs through mechanical forces that break up the structure by overcoming the interior bonding forces. After the grinding the

Learn MoreSAG Mill Grinding Circuit Design - Mineral Processing

SAG mill operation is more dynamic, and typically requires a higher degree of process control sophistication. Though more complex in AG/ SAG circuits relative to the crushing plants they have largely replaced, these issues are well understood in contemporary applications. See more

Learn MoreWhat's the Difference Between SAG Mill and Ball Mill

The working principle of the self-grinding machine is basically the same as the ball mill, the biggest difference is that the sag grinding

Learn MoreEvolution of SAG Mill Process Control at the Xstrata Nickel

PAPER 28. Evolution of SAG Mill Process Control at the Xstrata Nickel Raglan. Operation. Erik Bartsch1, Chief Engineer. Guy Comeau2 , Senior Metallurgist.

Learn MorePDF) Design and Implementation of Advanced Automatic Control Strategy

Due to the capacity feature of the third line, specially its SAG mill, it is a priority that the. The Copper Concentrator Plant of Compañía Minera Doña Inés de Collahuasi (CMDIC) is composed of three grinding lines, the third one being the largest. Due to the capacity feature of the third line, specially its SAG mill, it is a priority that the

Learn Moresag mill operation list - sag mill operation for sale

We doesn't provide sag mill operation products or service, please contact them directly and verify their companies info carefully. Total 9882 products from sag mill operation Manufactures & Suppliers

Learn MoreEXPERIENCES IN SAG MILL OPERATION - InterMet

Describe in detail SAG mill circuits of large-scale plants and the benefits of each. - Detail the issues occurred during SAG mill operation: blockage of grates, cracking of bolts,

Learn MoreSemi Autogenius Grinding (SAG) Mill

The SAG mill is often one of the largest pieces of mining equipment and is key for operations. Often used in the mining process of precious metals, the SAG

Learn MoreSAG Mill Control: It Shouldnt be that Hard

SAG mill control fundamentally means managing the load in the mill by adjusting the feed rate of ore to the mill and/or manipulating the rotational speed of the mill. The best way to measure load is to mount the mill on load cells.

Learn Moredegrussa milling circuit - critical issues, modifications and results

Option 1, a jaw crusher followed by a SAG mill and a ball mill was considered the best combination of capital cost, operating cost, ease of operation and

Learn MoreSag in Hillsboro, OR with Reviews - YP.com

Find 237 listings related to Sag in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for Sag locations in Hillsboro, OR.

Learn MorePDF) Operation Analysis of a SAG Mill under Different

This method simulates the particles size, mill power, and qualified particles quality of crushed particle, which reveal the grinding strength

Learn MoreSales Operations Supervisor Job Hillsboro Oregon USA,Sales

Sales Operations Supervisor. Job in Hillsboro - Washington County - OR Oregon - USA , 97123. Company: Pape' Kenworth. Full Time position. Listed on 2022-09-15. Job specializations: Sales. Area Manager, Sales Manager, Sales Associate.

Learn MoreSAG Mill Grinding Circuit Design - 911 Metallurgist

SAG mill operation is more dynamic, and typically requires a higher degree of process control

Learn MoreEnergies | Free Full-Text | Operation Analysis of a SAG Mill under

As one of the machines widely used in mining, a semi-autogenous grinding (SAG) mill can significantly improve the roughing efficiency of rock. But the SAG mill still faces the obstacles of significant energy consumption and empirical operation parameters. In order to obtain the optimal operation parameters of a SAG mill, in this paper, the discrete element method (DEM) is used to simulate the

Learn MoreSAG mill Optimisation and increasing throughput at the Phu Kham Copper-Gold Operation

8/30 · Mill Operators SAG mill Optimisation and increasing throughput at the Phu Kham Copper-Gold Operation – a success story This product is exclusive to Digital library subscription Subscribe SAG mill Optimisation and increasing

Learn MoreSAG Mill Process Control - Grinding & Classification Circuits

The purpose of a grinding mill is to convert electrical energy into rock breakage. The best use of that asset is to try to maximize the power draw. Try to hold the mill speed high and vary the feed rate to hold the weight (or bearing pressure), but watch out for "cycling" or "surging" that indicates instability in the charge.

Learn Moresag mill operation

to Design and Supply the World 39 s Largest SAG Mill in Peru . Oct 5 The 42ft diameter SAG mill is the world 39 s largest and the first of its kind time of the mill 39 s installation that after just the first week of operation

Learn MoreSAGwise™ total process control

Automatically minimise liner damage and power consumption, stabilise mill operations, and maximise production and efficiency with SAGwise™ total process cont

Learn MoreSAG Mill | Autogenous and Semi-Autogenous Mills

Your operation requires a Semi Autogenous Mill (SAG mill) or Autogenous Mill (AG Mill) that is flexible, durable, cost-efficient and tailored to your specific needs and use cases. That's why

Learn MoreComminution Circuit Design vs. Feed Size or 'Mine to Mill 2.0

current SAG mill operating conditions. – not setup for coarse material secondary crushed feed. – eliminate +100mm particles (P.

Learn MoreGearless mill drives - Grinding | ABB

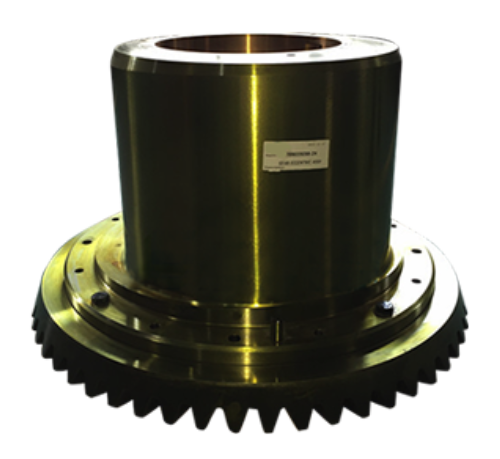

ABB’s GMD is the most powerful mill drive system in the market to power semiautogenous (SAG), ball and autogenous (AG) mills, This ’workhorse’ for grinding operations combines a robust, service-friendly and fit for purpose design to provide highest throughput, reliability and availability for your processing plant.

Learn MoreSAG Mill - Official Feed The Beast Wiki

The SAG Mill is a machine added by Ender IO. It uses Micro Infinity (µI) to grind (or mill) items into their crushed variants, like Ores into Dusts. The SAG Mill has four output slots; recipes can have 1-4 different outputs, with different chances of obtaining those outputs.

Learn MoreSAG Mill Optimisation and Increasing Throughput at the Phu Kham Copper

The Phu Kham Operation has recently undergone a series of process improvements to treat the anticipated competent ores scheduled for and 2018. The operation's comminution circuit, which comprises a semiautogenous (SAG) mill and two ball mills, each with 13 megawatts (MW) of installed power, was expected to be SAG mill limited when

Learn MoreSAG Mill | Autogenous and Semi-Autogenous Mills

Your operation requires a Semi Autogenous Mill (SAG mill) or Autogenous Mill (AG Mill) that is flexible, durable, cost-efficient and tailored to your specific needs and use cases. That's why we offer a full product range from 4.3m to 12.2m in diameter with multiple options for configuration of designs to suit your operation:

Learn More

Leave A Reply