CN202643569U - Composite cement cooler - Google Patents

A composite cement cooler is characterized by comprising a motor (1), a stirring groove (4), two parallelly arranged stirring shafts (5), stirring blades (6), heat exchange sheets (9) and a fluidization cavity (12), wherein the two stirring shafts (5) penetrate through the inside of the stirring groove (4), the motor (1) is connected with the two stirring shafts (5), the stirring blade

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

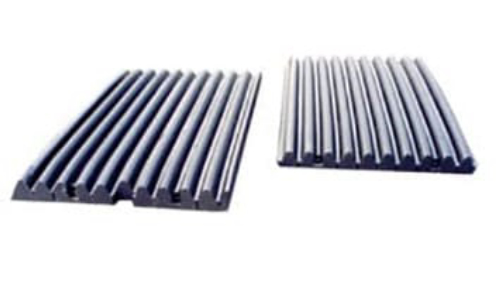

The grate cooler adopts a modular construction design, is flexibly adaptable to different scales of the cement kiln. There is no need of conveying equipment for material leakage under the grate

Learn MorePDF Hotter Cements, Cooler Concretes - NISTPDF

Concrete international / January 41 by Dale P. bentz, Casimir J. bognaCki, kyle a. riDing, anD ViCtor H. Villarreal Hotter Cements, Cooler Concretes Finer cements may require engineered solutions to reduce the maximum temperature rise in concretes Many things have changed in the concrete industry during the past 50 years, including the basic

Learn MorePyrofloor²® - KHD Humboldt Wedag

The cooler is the last step in the clinker production process. In fact, at a Turkish cement plant that was among the first Pyrofloor® cooler

Learn MoreClinker Cooler - Cement Cooler | AGICO Cooler In Cement Plant

As the supporting equipment of cement rotary kiln, clinker cooler (also called cement cooler) is a kind of heat exchange device that transfers heat from high-temperature clinker to low

Learn MoreRotary Cooler - Cement Cooler | AGICO Cooler In Cement Plant

The main purpose of cement rotary cooler: Reduce the temperature of the clinker as low as possible for subsequent grinding, transportation, and storage. Recycle the heat energy from the clinker as much as possible to heat the secondary and tertiary air, making them combustion air and minimizing the fuel consumption of the cement rotary kiln system.

Learn MoreCement Cooling System - Efficient, Industrial Cement Cooler | Solex - Solex

The cooling of cement is an important step prior to storage in mitigating gypsum dehydration and subsequent moisture liberation which can lead to lump formation. Recommendations vary but it is generally accepted that with mill outlet temperatures of around 110ºC - 120ºC, cooling to below 80ºC is necessary to avoid this reaction.

Learn MoreClinker Cooler - Grate Cooler Latest Price, Manufacturers

Coolers are used with rotary kilns to rapidly cool hot clinker or other materials exiting the kiln. - The latest generation clinker cooler of Sinoma-tec has

Learn MoreClinker Cooler - 911 Metallurgist

The Air-Quenching shaking grate Clinker Cooler was developed more than 20 years ago as an improved heat recuperating cooler for use with

Learn MoreGrate Cooler in Cement Plant | Cement Clinker Cooler for

The grate cooler in a cement plant cools and transports the cement clinker from the rotary kiln, and provides heating air (secondary air) for the rotary kiln and preheater. The performance of

Learn MoreFind a recycler | Metro

Loads of mixed dirt, rock, asphalt and concrete. May include other fill materials, but no organic materials. Some recyclers may accept red brick in the mix. Salvaged and used building material More information. Used building materials in good reusable condition. Contact the recycler for information about specific materials. Sand; Sawdust; Terra

Learn MoreRotary Cooler | Clinker Cooler In Cement Plant | AGICO CEMENT

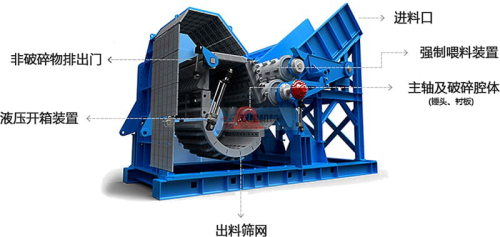

Rotary cooler in cement plant In cement production line, most of the cement raw materials must be broken, such as limestone, clay, iron ore and coal. Finally, cement clinker coolers cool the high temperature clinker discharged from rotary kiln and convey to storage silo and cement grinding plant. rotary cooler projects Advantages of rotary cooler

Learn Moreperformance evaluation of a grate cooler in a cement ... - IJSEAS

this study, the performance of a grate cooler in Ibese cement manufacturing industry in. Nigeria has been examined using the mass and heat

Learn MoreCN103743264A - Cement rapid cooler - Google Patents

1. a cement flash cooler, is characterized in that: comprise air blast (1), cooler bin (2), dust arrester installation (3); described cooler bin (2) top is provided with hot cement entrance (4),

Learn MoreWhite cement cooler - thyssenkrupp Industrial Solutions

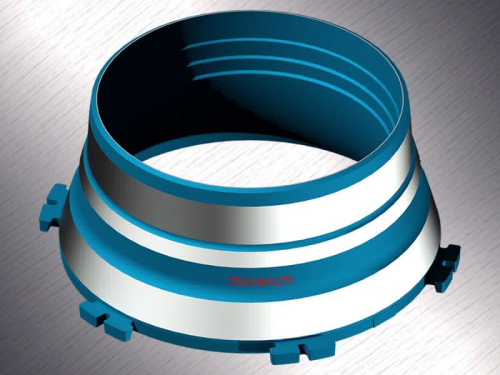

Especially for the white cement production process, thyssenkrupp Industrial Solutions developed the twin cooler, consisting of rotary cooler, roll crusher

Learn MoreGrate Cooler – Clinker Cooler | AGICO Grate Cooler In Cement Plant

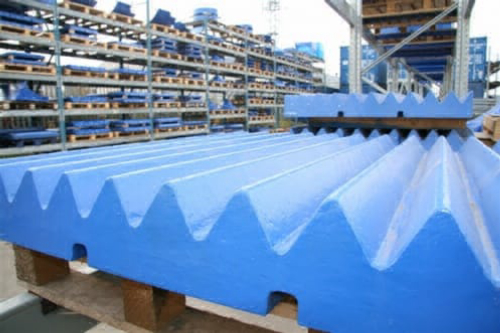

Grate cooler, as a quench type clinker cooler, is the important cement equipment in the clinker calcination system. Its main function is to cool and transport cement clinker. Meanwhile, provide hot air for cement rotary kiln and precalciner.

Learn MoreClinker coolers - SKF

Much like the rotary kilns that feed them, clinker coolers in cement making are also subject to extremely high operating temperatures and dust levels.

Learn MoreEvaluating the thermodynamic efficiency of the cement grate

ASPEN Plus and neural networks predictive model were used to model, simulate and predict the grate clinker cooler in this paper. First, the process flow model

Learn Morecement coolers, cement coolers Suppliers and Manufacturers at

Cement Coolers (916 products available) 1/3 A Cooler Corona Ice Chest Cooler Box $55.00-$80.00 / piece 50.0 pieces (Min Order) CN Wuyi Beyond Tools Co., Ltd. 15YRS Contact Supplier 1/6 lattmo OEM 840D TPU,CementGray Hopper Flip 24 Can Portable Buckets Cooler, airtightInsulated leakproof Zipper Soft Sided Cooler $45.00-$53.00 / piece 50 pieces

Learn MoreCement Directory: Clinker Coolers

Al Bijjar Trading (FZC) is the leading supplier to the Cement Industry worldwide and specially in th . Fons Delta Cooler Clinker Cooler Manufacturer

Learn MoreConcrete Freezer & Cooler Crack Repair Products | KwikBond

KWIK-BOND is designed for industrial concrete floor repair on frozen surfaces such as freezers, coolers, and holding boxes. You can set up and cure without the need to raise surface temperatures, use propane torches, or heating lamps to accelerate the cure. KWIK-BOND can be used anywhere a quick set is desired, in any temperature range.

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant Equipment

The grate cooler adopts a modular construction design, is flexibly adaptable to different scales of the cement kiln. There is no need of conveying equipment for material leakage under the grate bed. The adjustment and optimization of the grate bed help to cool clinker uniformly. High thermal efficiency. High conveying efficiency.

Learn More1 in Cement/Concrete Cooling in Hillsboro OR

1 Source for Emergency & Temporary Cement/Concrete Cooling in Hillsboro OR = Paratus Rentals 855-313-7368 If you use cold water to help hydration in your aggregate mixing process, we have the help you are looking for. Paratus Rentals is your #1 source for Cement/Concrete Cooling in Hillsboro OR! If you are operating a Cement/Concrete plant in

Learn MoreCement Hillsboro, OR - E Ready Mix Concrete

Ready Mix Concrete in Hillsboro, Oregon. EReadyMixConcrete.com is the top source for ready mix concrete in Hillsboro, OR. You can quickly get prices on ready mix from the leading Hillsboro concrete suppliers. Fill out the quick quote form to compare prices on concrete products and services in Hillsboro, Oregon. Hillsboro, OR Concrete Prices

Learn MoreClinker Cooler, Cement Cooler, Grate Cooler | Clinker

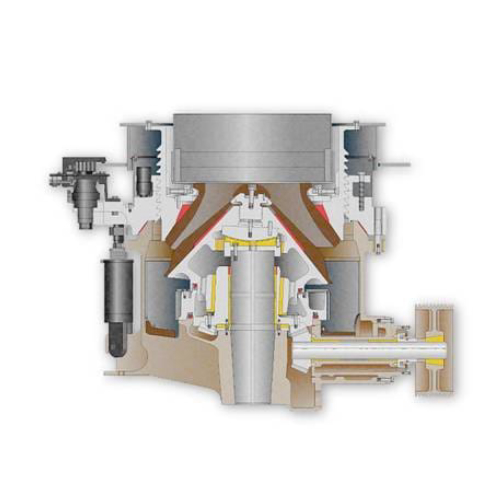

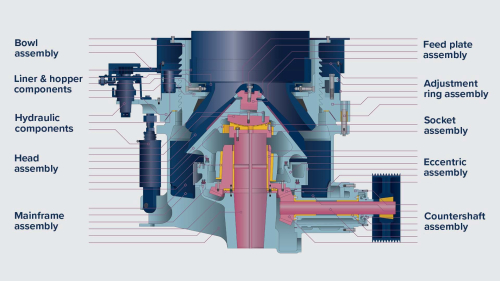

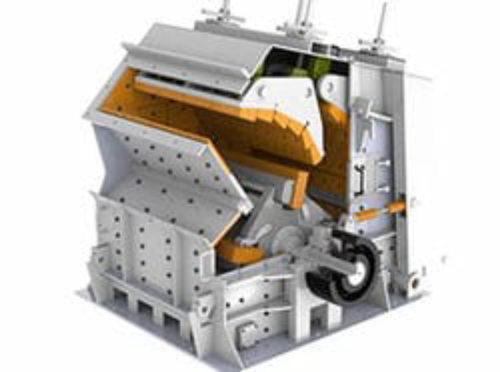

The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker production. The clinker cooler is mainly used to cool and transport the cement

Learn MoreGrate Cooler in Cement Plant

The grate cooler in a cement plant cools and transports the cement clinker from the rotary kiln, and provides heating air (secondary air) for the rotary kiln

Learn MoreTemperature control during clinker cooling process

Modern clinker coolers have an air flow perpendicular to the clinker flow, absor thermal energy. This hot air is used almost entirely as secondary air for

Learn MoreCN203382669U - Cement cooler - Google Patents

The utility model relates to the technical field of cement processing equipment, and in particular relates to a cement cooler. The cement cooler comprises a cooler body, wherein a discharge

Learn MoreClinker Cooler Unit - FONS Teknoloji

Clinker Cooler Unit During the cement production, the raw material reaches a temperature of about 1450 ° C in the kiln. The clinker particles, which are first

Learn MoreImpact of clinker coolers on downstream equipment

Clinker coolers in today's cement pyroprocessing lines are considered to be very reliable even under kiln upset conditions. But what is the interaction of

Learn Morecement coolers, cement coolers Suppliers and Manufacturers at

offers 916 cement coolers products. A wide variety of cement coolers options are available to you, such as use, material, and feature.

Learn More

Leave A Reply