Virtual-Lab of a Cement Clinker Cooler for Operator Training

A virtual-lab of a clinker grate cooler, intended for training of cement plant operators, has been developed. The grate cooler model has been derived from

Learn MoreWhy a New Clinker Cooler? - Congreso Técnico

Cooler with WHR. 32. Replacement of grate cooler. 18. Behind wet kiln. 3. Return flow. 2. Replacement of satelite cooler. 4. In operation.

Learn MoreUpgrading a clinker cooler: IKN clinker inlet distribution

The clinker cooler is exposed to extremely difficult operating conditions with a highly abrasive and hot material. When leaving the rotary kiln, clinker is in

Learn MoreClinkerization - Cement Plant Optimization

Maintaining constant clinker bed height is a key to stable cooler operation. Undergrate pressure reflects bed resistance and changes with clinker size. To maintain constant Undergrate

Learn MoreClinker Cooler | PDF | Mechanical Engineering | Building Engineering

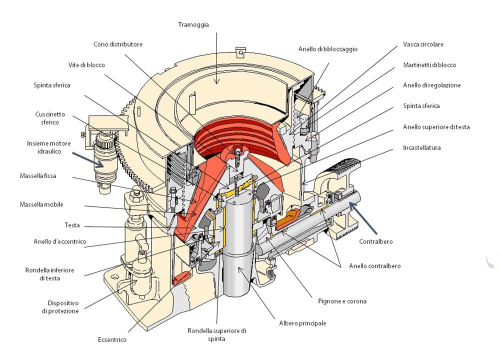

CLINKER COOLER Reduce clinker temperature from approx. 1400 o C to approx 100 ~ 200 o C The heat of the incoming clinker is recuperated in the secondary air of Kiln An efficiency of incoming clinker heat usually lies within 65 ~ 75% 3 Clinker Cooler Type 1. Grate Cooler Cross flow heat exchange through clinker bed with cold air

Learn MoreClinker Cooler, Cement Cooler, Grate Cooler | Clinker Production

The cooler will make a sufficient heat exchange between the clinker (1000-1200℃) from the rotary kiln and air by cooler rotating, so that the material can be cooled to (below 200℃), and improve the clinker quality and grindability, our clinker cooler with the features of simple structure, high transport rate, easy operation and maintenance.

Learn MoreClinker Cooler - 911 Metallurgist

The Air-Quenching grate cooler is simple in design and operation. The entire cooler is composed of a single operating unit. The

Learn MoreGrate Cooler in Cement Plant | Cement Clinker Cooler for Sale

Grate Cooler Working Principle The hot clinker discharged from the rotary kiln falls on the grate bed. Under the push of reciprocating grate plate, the hot

Learn MoreIBig coolers, big challenges - IKN

IKN Pendulum Coolers with a nameplate capacity clinker lines similar to those procured by the Anhui Conch trouble-free cooler operation. Neither the.

Learn MoreCross-Bar® Cooler for efficient clinker cooling

The Cross-Bar® Cooler gives you efficient clinker cooling and low maintenance and operating costs.

Learn MoreEFFICIENCY, RECUPERATION AND HEAT LOSS - Clinker Coolers

For the same cooler working with the same type of clinker, the heat recuperation will depend on the amount of combustion air that goes from the cooler to the kiln. This amount again

Learn MorePDF Portland Cement Manufacturing Industry NESHAP Summary of RequirementsPDF

Table 1—Emissions Limits for Kilns, Clinker Coolers, Raw Material Dryers, Raw and Finish Mills If your source is a (an): And the operating mode is: And if is located at a: Your emissions limits are: And the units of the emissions limit are: The oxygen correction factor is: 9. New clinker cooler Normal operation Major or area source

Learn MoreClinker Aeration by Coanda Wing® - IKN

20/02/ · The Coanda Wing® plates allow air to pass but not clinker. Fines are swept to the clinker bed surface and the Coanda Wing® plates are completely surrounded by cooling air. During normal operation, temperatures of between 30° C and 40° C are measured close to the grate surface. Coanda Wing® blade

Learn MoreOn-site services for clinker coolers

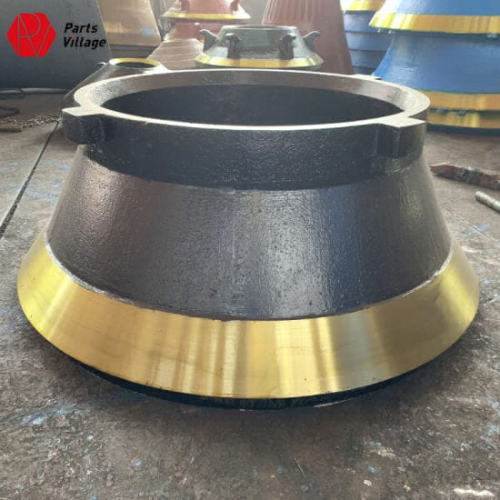

The clinker-cooler is working constantly for your plant and preventative maintenance is vital to keep availability high. You need to avoid excessive we components, and have the right spare parts on hand for planned maintenance. After a complete cooler overhaul, to ensure the best possible start to your operations, we'll stay on-site

Learn Moreinside parts of clinker cooler encyclopedia

Clinker cement Wikipedia. Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types In the cooler the air is heated by the cooling clinker so that it may be 400 to 800 °C If part of the fuel necessary to burn the rawmix is burned outside the kiln the output of the system can be increased for a given kiln sizeClinker At the outlet of the kiln the clinker

Learn MoreClinker Plant | Cement Plant | Cement Equipment For Clinker Production

Clinker cooler: the clinker cooler is heat exchange equipment, clinker cooler use air as medium, pass through the high-temperature clinker and cool the cement clinker, at the same time, recovery the waste heat, promote the thermal efficiency.

Learn MoreLatest trends in clinker cooling - Cement Lime Gypsum - ZKG

It discusses the important parameters determining the efficiency of a clinker cooler and shows how the solutions and market shares of the individual plant engineers differ. Clinker inlet distribution system and a method for operation (22) 29.11. (43) 02.06. (57) Clinker cooling with a cooling grate having a receiving section

Learn MoreD9.2 Analysis of oxyfuel clinker cooler operational performance

Lower clinker production rates together with cold false air ingress decreased the temperature of the pilot cooler exhaust gas. For such operation conditions the

Learn MoreClinker Cooler - Cement Cooler | AGICO Cooler In Cement Plant

Clinker cooler transfers heat from clinker to combustion air to improve the heat exchange process and reduce fuel consumption to some extent. obtain clinker at an appropriate temperature for further grinding, storage and conveying. The cement clinker after sintering is not the final cement product sold in the market.

Learn MoreUS2598931A - Clinker cooler - Google Patents

There are a number of variations of this type of cooler, but the basic principle of the operation is the same, that is, passing cooling air through the

Learn MoreClinker Cooler Operation

26/02/ · Providing information for people working in cement plants, those who want to improve the way they work.

Learn MoreCLINKER COOLER SECTION - Kiln Operation

In document Kiln Operation (Page 77-83) COOLER. FUNCTION. a) The main function of the cooler is to recuperate the heat contained in the clinker coming from the kiln as heat recovery from

Learn MoreCement Cooler - Clinker Cooler | Types Of Clinker Cooler AGICO

Clinker enters from one end and is lifted and scattered by flights. At the same time, the cold air enters from the other end and contacts with the clinker countercurrent for heat exchange. The rotary cooler is generally arranged under the rotary kiln, with a diameter of 2-5m and a length of 20-50m. Grate cooler Grate cooler is a quench type cooler.

Learn MoreUSE OF AN INNOVATIVE CLINKER COOLER TO SAVE

In the reciprocation grate coolers used until now in rotary kiln cement plants Operating experience to date shows that the redesigned clinker cooler has

Learn MoreEvaluating the thermodynamic efficiency of the cement grate clinker

The operating functions of the grate clinker cooler include: on the inclined fixed grid plate, the clinker in the rotary kiln is dropped and the moving grate plate moved the clinker forward with the aid of the moving bar.

Learn MoreKiln and Cooler - INFINITY FOR CEMENT EQUIPMENT

Under normal operating conditons (stable operation), there is an undergrate pressure for each compartment that ensures

Learn MorePDF Industrial Solutions polytrack clinker cooel r - ThyssenKruppPDF

Industrial Solutions | polytrack ® clinker cooler 2 Technical specifications Clinker bed height Installed Operation Grey and white cement, minerals 500 - 12,000 tpd 42 - 45 t/m 2/d 800 - 1,500 t/m/d ≥ 800 mm 2.0 - 2.2 Nm 3/kg cl 1.7 - 1.9 Nm 3/kg cl Hydraulics Stroke length

Learn MoreClinker Cooler Operation | PDF - Scribd

CLINKER COOLER OPERATION.doc - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free.

Learn MoreCross-Bar® cooler

12/07/ · By further refining the best elements of proven cooler designs, the ® Cross-Bar® cooler gives the highest standard in cement clinker cooling technolo

Learn MoreClinker Cooler - A Vital Unit in Cement Pyro Section - Techcem

Typically, the clinker coolers release large amounts of heated air at 250 to 340° C which can effectively be used in WHRS system. The steam turbine based waste heat recovery boilers (WHRB) are placed between the cooler and the de-dusting system. Depending on situations / requirements, various configurations are considered which are shown below.

Learn MoreLatest Developments in High Efficency Clinker Cooling

Clinker Cooler Drive - Safeguard operation Failure mode: Modern ETA Cooler Traditional Grate cooler Failure of one pump Bypass is opened, clinker production continues Standby pump must be activated Failure of one lane drive Production continues at almost 100% Capacity

Learn More

Leave A Reply