PDF Mass balance control of crushing circuits - trepo.tuni.fiPDF

This enables the circuit to reach its true potential. Keywords: Crushing, Mass balance control, Limiting control, Dynamic modeling, Sensor fusion 1. Introduction Crushing is an essential multi-stage processing step in the production of minerals, metals, aggregates, and cement. A crushing circuit comprises a combination of unit operations for

Learn MoreThe pros and cons of cone crusher applications - Quarry

In any crushing circuit, it is good common sense to get the material to the product piles as quick as possible. This will reduce the wear and te the equipment and can lead to increased efficiency and capacity of the circuit because the finished product is not taking up room on the screens, conveyors, and in the crushers.

Learn MorePDF Crushing and Screening Handbook - AusIMMPDF

Portable crushing plants - excellent trans-portability between sites and fast installation, in addition to high crushing capacities. Can be fi tted with jaw, cone or impact crushers, with or without screens, and equipped with open or closed circuit and discharge conveyors. Mobile screens - track-mounted units for ex-

Learn MoreCrushing Circuit - Fortuna Silver Mines Inc

Secondary crushing circuit stockpile, tertiary-HPGR crushing circuit, and agglomeration plant · Primary crushing circuit ramp up phase.

Learn MoreA closed loop secondary crushing circuit. - ResearchGate

Download scientific diagram | A closed loop secondary crushing circuit. from publication: Crushing Plant Dynamics | | ResearchGate, the professional network

Learn MoreA CASE STUDY ON VERTICAL SHAFT IMPACT C - DergiPark

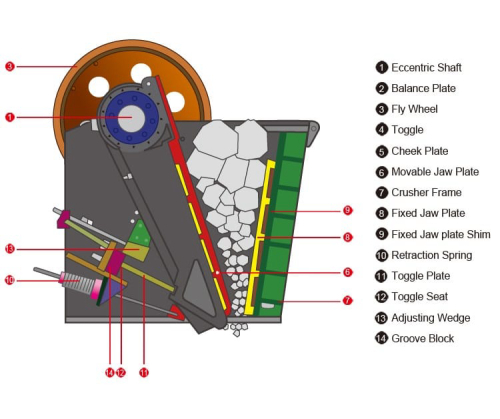

that rock aggregates produced through jaw and cone crushing circuits have a better cubical form when compared to those produced from the jaw crusher

Learn MoreCrushing Plant Design and Layout Considerations - JXSC Mine

The basic types of the three-stage crushing process are three-stage open circuit and three-stage one closed circuit. The three-stage and the one-closed crushing process has been widely used as a preparation for grinding. Whether it is underground or open-pit mining ore, as long as the ore is not high in mud, it can be effectively adapted.

Learn MoreGrinding Circuit - an overview | ScienceDirect Topics

7.5.2 Circuit Operation. Grinding circuits are fed at a controlled rate from the stockpile or bins holding the crusher plant product. There may be a number of grinding circuits in parallel, each circuit taking a definite fraction of the feed. An example is the Highland Valley Cu/Mo plant with five parallel grinding lines (Chapter 12 ).

Learn MoreCrushing and Grinding - The Weir Group

A leading supplier to the aggregate industry. Our range of crushers provide optimised crushing circuits that match your needs, from single crushers to complete turn-key processing plants. Supported by expert, highly skilled service teams providing 24/7 global product training and support. Recently the Weir Minerals team partnered with an Iowa

Learn MoreWhat Is Primary, Secondary, and Tertiary Crushing?

These stages in addition to secondary crushing can often be laid out utilizing an open-circuit portable crusher plant system where processed material is screened and conveyed from one crusher to the next. Relying on these many stages of crushing beyond only primary can add great value to a crushing operation.

Learn MoreClosed Circuit Crushing | Crusher Mills, Cone Crusher, Jaw Crushers

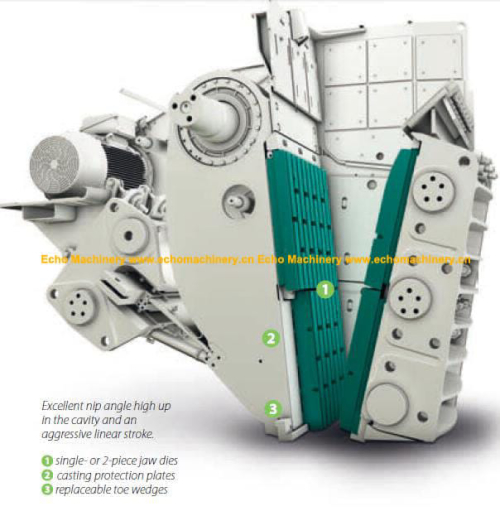

Three-section crushing circuit. There are two basic form of the circuit: three-section open circuit and three-section closed circuit. three-section closed circuit, as the Closed circuit crushing - Evoke Wiki The Lippmann Jaw Crusher is fantastic for stationary, skid-mounted, or portable and mobile primary smashing programs.

Learn MoreHPGR in Pebble Crushing Circuit - Videos

By adding a HPGR to the pebble circuit, the crushed pebbles can be further reduced and sent directly to the ball mill.

Learn MoreHow To Balance A Crushing Circuit | McLanahan

A balanced crushing circuit provides flexibility with production and ultimately allows you to be more profitable. During this webinar, we look at ways to identify factors that may have your

Learn MoreApplying the Digital Twin to Crushing Circuits | Emerson

of the crushing circuit. Crushing Circuit Modeling. Solutions for crushing circuit units include dynamic models of the following process areas:.

Learn MoreCrushing Circuit Process Control - Metallurgist & Mineral Processing

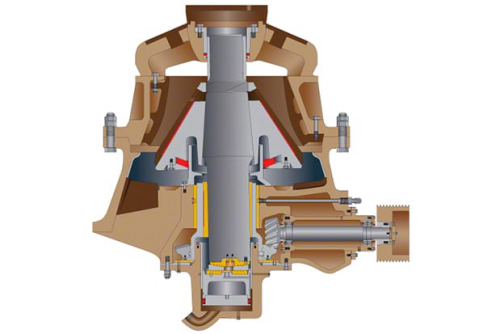

The plant consists of normal components presently utilized in crushing and screening plants, but we believe the control system and the method of arranging the energy balance to be unique. The diagram for simplicity shows a two-stage cone crusher reduction operation, but the system can be applied to any number of crushing stages.

Learn MoreThree ways to improve your crushing circuit for increased

Aug 22, · There are a couple of steps to optimizing a crushing circuit– firstly to optimize machine performance, and secondly to optimize the overall performance of your circuit.

Learn MoreCrusher services - Outotec

Get the most out of your crushing circuit. Whether you are looking to minimize downtime, increase capacity, lower your cost per ton, or meet specific size-reduction requirements – Outotec can support you. Outotec crushing equipment and process specialists use ore characterization data, comprehensive plant surveys, and

Learn MoreHandbook of Crushing - TerraSource Global

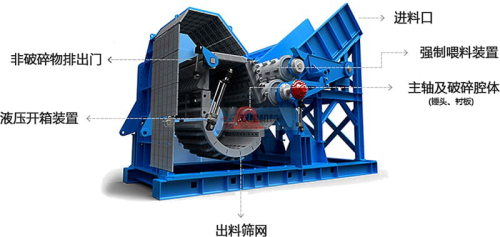

hammers and screen bars, it is practical for crushing the less abrasive materials such as pure limestone and coal. Attrition crushing is most useful in the following circumstances: • when material is friable or not too abrasive • when a closed-circuit system is not desirable to control top size Shear Shear consists of a trimming or cleaving

Learn MoreModeling and control of a crushing circuit for platinum

Semantic Scholar extracted view of "Modeling and control of a crushing circuit for platinum concentration" by M. Johansson.

Learn MoreMass balance control of crushing circuits - Trepo

This paper describes a novel circuit-wide control scheme that addresses the challenging problem of mass balance control of crushing circuits.

Learn MoreMineral Processing Circuit Upgrade | OPS Consulting Case

The Problem: Our client needed to upgrade their mineral processing circuit to crush and screen existing stockpiles of already crushed Basalt.

Learn MoreThree ways to improve your crushing circuit for increased production

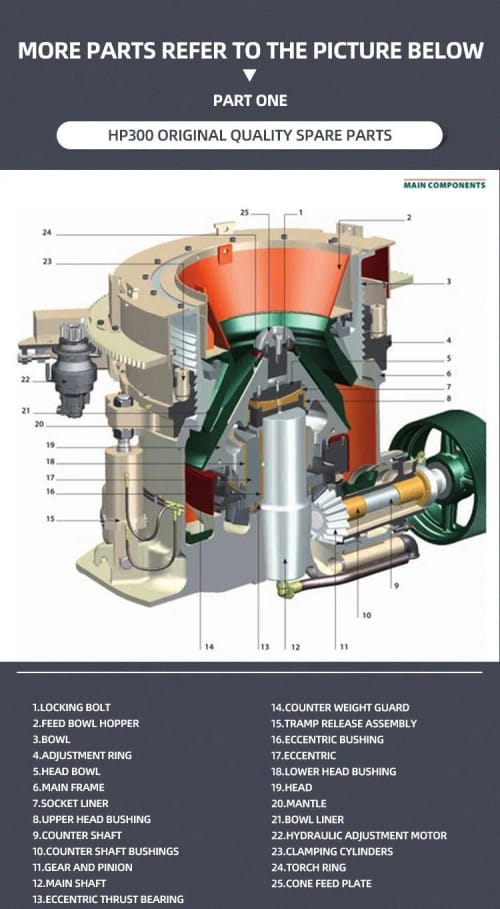

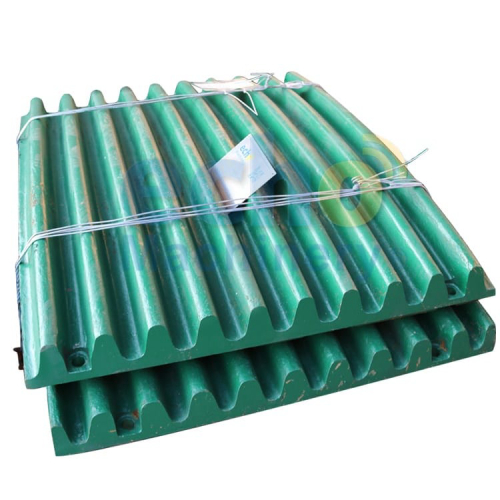

There are a couple of steps to optimizing a crushing circuit- firstly to optimize machine performance, and secondly to optimize the overall performance of your circuit. Optimizing a machine involves verifying all aspects of your equipment to maximize process and mechanical performance. The crusher's chamber is a good place to start.

Learn MorePDF Handbook of Crushing - TerraSource GlobalPDF

hammers and screen bars, it is practical for crushing the less abrasive materials such as pure limestone and coal. Attrition crushing is most useful in the following circumstances: • when material is friable or not too abrasive • when a closed-circuit system is not desirable to control top size Shear Shear consists of a trimming or cleaving

Learn MoreClosed Circuit Crushing Plant | ELRUS Cone Crusher

ELRUS Closed Circuit Crushing Plant. elrus-closed-circuit-plant-699-308. Chassis features: ELRUS HD 16 wheel suspension; Six (6) blocking legs; Airbrakes,

Learn MoreArcadia crushing circuit now operational, production nextweek

Jun 16, · The crushing circuit is operational, with production to start within the next week!” the company said. The company Managing Director Sam Hosack commending on the development on Twitter said: “Commissioning is always the most challenging and rewarding part of a project, tackling arising issues and having the commitment to deliver on your goals.

Learn MoreCrusher - an overview | ScienceDirect Topics

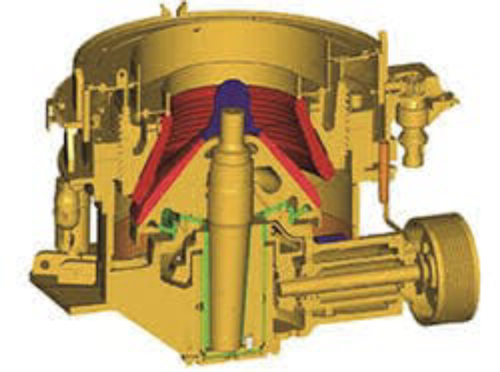

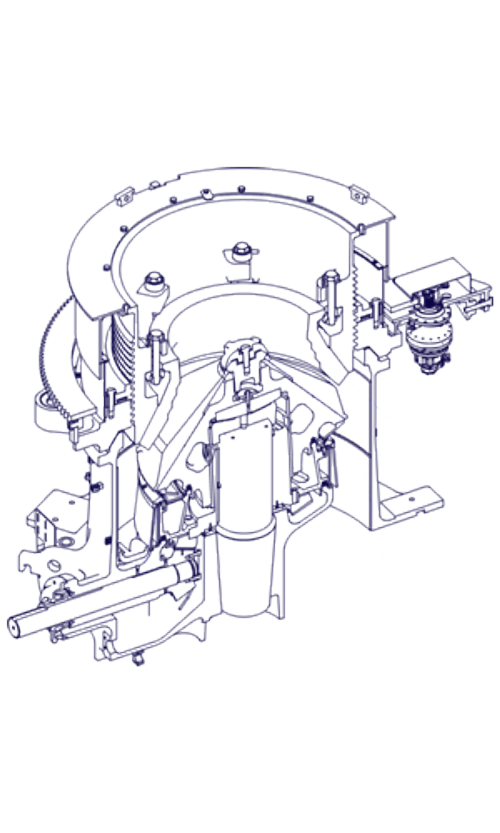

Crushing is accomplished by compression of the ore against a rigid surface or by impact against a surface in a rigidly constrained motion path. Crushing is usually a dry process and carried out on ROM ore in succession of two or three stages, namely, by (1) primary, (2) secondary, and (3) tertiary crushers. 13.3.1.1 Primary Crusher

Learn MoreUse of a simplified method to calculate closed crushing circuits

Abstract. The present work deals with new developments in calculating the performance of closed crushing circuits (regular and reverse). In previous works, some simple equations descri these

Learn MoreOptimization of Comminution Circuit Throughput and Product

Abstract The goal of this project was to improve energy efficiency of industrial crushing and grinding operations (comminution). Mathematical models of the comminution process were used to study methods for optimizing the product size distribution, so that the amount of excessively fine material produced could be minimized.

Learn MoreMineral Processing Mining Rock Crushing Circuit and

According to the difference size of raw ore & crushed products and crushing capacity, crushing systems can be divided into open circuit and closed circuit.

Learn MoreTrio® Crushing Equipment - The Weir Group

We can even help you build an entire crushing circuit from start to finish to maximise efficiency and tonnage. Trio Crushing Equipment | Weir Minerals

Learn MoreSecondary & Tertiary Crushing Circuits - Mineral Processing & Metallurgy

This one involves both SECONDARY and TERTIARY crushing. This circuit is employed where either the tonnage or the work index of the ore is high enough to require that the crushing be done in stages. Again the ore will come from a Primary crusher and be scalped. The coarse material will be crushed by the secondary crusher.

Learn More

Leave A Reply