Materials and their properties - Home Shop Machinist

Aluminum is easy to machine, light weight, quite cheap and provides good starting point for learning to use your machine. Brass is quite heavy,

Learn MoreMachining Guidelines - Crystallume

Aluminum (5–8% Si) (356, 308, 242, 208), Rough Milling, 2000–5000, 610–1525, 0.010–0.020 Copper, Milling, 750–1500, 230–460, 0.001–0.008, 0.025–0.200.

Learn MoreBeryllium Copper Machining - Wonder Copper

Beryllium copper 172 is also non-magnetic and has a very low permeability, making it a suitable choice for magnetic housings. BeCu 172 has a machining cost factor of 3.0 when compared to steel 12L14. It is good for soldering, brazing, forging, welding, and hot and cold working. BeCu 172 can be annealed. Beryllium copper alloy 173 (BeCu) is a

Learn MoreCopper Clad Aluminum Wire VS Pure Copper Wire: What's the Difference

However, the copper clad aluminum of the same weight is much longer than the pure copper conductor, and the cable is calculated according to the length. With the same weight, copper-clad aluminum wire is 2.5 times the length of copper wire, and the price is only a few hundred yuan per ton. Taken together, copper-clad aluminum is very advantageous.

Learn MoreCopper Water Block - Practical Machinist

2058. If the copper is too gummy, they don't know what they're doing. Now the most common heat sink system is a water block made of aluminum with a copper contact insert, and using silver thermal paste between the chip and copper to aid in thermal transfer. Then the water is pumped back to an aluminum block with heat dispersion fins and usually

Learn MoreVarious Machining Copper Vs Aluminum of High Quality, China Machining

Machining Copper Vs Aluminum, Buy Various High Quality Machining Copper Vs Aluminum Products From China Manufacturer. Company Details. Hong Kong RYH CO., LTD [Guangdong,China] Business Type: Manufacturer; Main Markets: Americas , Asia , Europe , Middle East , Oceania; Exporter: 81% - 90%;

Learn MoreCutting Speed Chart for Different Materials in Turning

2020. 4. 20. · Machining process: cutting speed for turning, drilling, reaming, and end milling. 3. Please note the table is applicable for high speed steel tooling, when you use carbide tooling,

Learn MoreControlling Warpage in Aluminum - CR4 Discussion Thread

2008. 7. 25. · The warping is cause because the stress is coming out of the part as you remove material. You could try to send this to a heat treater for stress relieving before you machine it. But seeing that it's such a thin part, surely the part is restrained during assembly and it stays restrained during it's life.

Learn MoreWire electrical discharge machining of aluminum alloy with

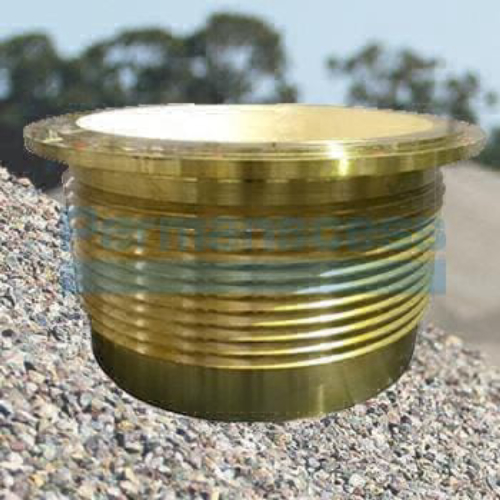

The 0.25 mm brass wire was used as a tool electrode. The aluminum type machining parameters were adopted for the wire cutting. INTRODUCTION. Wire Electrical

Learn MoreTitanium Vs. Aluminum: Choosing Lightweight Metal for ... - rapiddirect

Titanium is not a good conductor of electricity because it exhibits only about 3.1% of the conductivity of copper. Therefore, it is not used where good conductivity is a prime factor. However, aluminum exhibits 64% of the conductivity of copper. It is a relatively good conductor of electricity.

Learn MoreUnderstanding Beryllium | American Machinist

If the machinablility factor of free-machining steel is rated at 100 percent, the machinability factor or beryllium is 55 percent. Using the same comparison, titanium and its alloys range from 18 to 38 percent and aluminum and brass are 120 to 200 percent.

Learn MoreInfluence of Copper Content on 6351 Aluminum Alloy

The machinability of 6351 (T6) alloy was investigated and the results showed that machining tools with PCD (polycrystalline diamond) compared with carbide tools

Learn MoreVarious Machining Copper Vs Aluminum of High Quality, China

Machining Copper Vs Aluminum, Buy Various High Quality Machining Copper Vs Aluminum Products From China Manufacturer. Company Details. Hong Kong RYH CO., LTD

Learn MoreCopper Vs. Aluminum - The Tug-of-War Between GC and Electrician

Back in the 1960s and 70s, about 2 million homes in the US were wired with aluminum. It was the peak of the Vietnam war and there was a big shortage of copper in our country. Aluminum was cheaper and lighter in weight, and it had been approved back in 1945 for use in home wiring. So why not!

Learn MoreCopper Grades Available for CNC Machining - Parts Badger

When it comes to machining, pure copper has poor machinability due to high plasticity and toughness. Alloying the copper with elements such as zinc, tin,

Learn MoreWhat's the Difference Between Aluminum and Copper in Electrical

For wires, Al can be up to 60% lighter than comparable current carrying copper wires." Relays, sensors, switches, and small motors can use control cables for on/off control applications for signal

Learn MoreCopper Material Properties: Brass VS Red Copper - SANS

In terms of hardness index, the hardness of brass ranges from 3 to 4. On the other hand, the hardness of red copper is 2.5 - 3 on the metal harness diagram. Brass is the product of different components of copper and zinc. The higher the zinc content, the better the hardness and ductility of brass.

Learn MoreMachining Copper (C14500) on the Nomad - #MaterialMonday

2019. 5. 6. · Certain grades and condition of copper are good to machine, like Tellurium Copper (C14500). Here we go over some usable recipes you can use as you learn to c

Learn MoreMACHINING C110 Copper Vs C360 Vs Aluminum 6061 - Eng-Tips

2014. 9. 25. · Forget the C110 copper, and use either 6061-T6 or C360 brass. 6061-T6 will have a good surface finish when machined properly (specific feeds & speeds, tool geometry, coolant).

Learn MoreBrass Machining vs. Aluminum Machining - Custom CNC Machining 5-axis CNC Machining

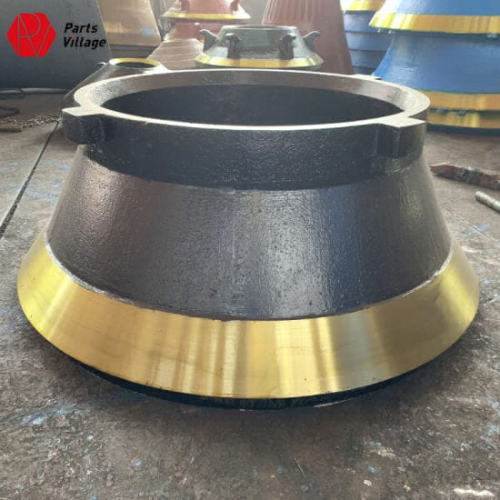

2022. 9. 1. · Applications – Brass Machining and Aluminum Machining. Aluminum and brass are used in several applications, including musical instruments to aeronautical components. Brass Figure 3: Applications of Brass Machining. Brass is an alloy of copper and zinc that has a wide range of applications due to its durability, machinability, and corrosion

Learn MoreStainless steel vs aluminum, which is better for CNC machining project

Using copper as a reference, aluminum has a conductivity of 61% and is about 30% lighter than copper. The conductivity of stainless steel is 3.5% of that of copper, making it a poor conductor of electricity. Aluminum is the ideal material if conductivity is the first element for your CNC machining project.

Learn MoreSpecialized Machining Copper Vs Brass manufacturer in China, Machining

Machining Copper Vs Brass Manufacture and Supplier in China. Select Language. English. Inquiry Basket ( 0 ) Company Details. Hong Kong RYH CO., LTD [Guangdong,China] Customized small CNC machining aluminum components. Customized CNC machining stainless steel long parts. CNC machining of rectangular aluminum parts.

Learn MoreCopper Material | CNC Machining 101 & 110 Copper - Fictiv

Pure copper CNC machining is very difficult to and requires specialized knowledge. Alloying the copper with elements such as tin, silicon, zinc, aluminum, and

Learn MoreChina Machining Copper Vs Brass Manufacturer, View Machining Copper Vs

Customized Black Anodizing CNC machining Aluminum Parts. Min. Order: 1 Bag/Bags Productivity: 4600/Month Transportation: Ocean,Land,Air Customized Black Anodizing CNC machining Aluminum Parts There are many materials processed by CNC machine tools of which aluminum is one of the most processed materials When using CNC machine tools to process aluminum parts you must pay attention to these

Learn Moretoxicology - copper vs aluminum, what's the safest for health

While the effects of life long dosing of Al are becoming more and more clearly tied to Alzheimer's (4), the effects build up over time. Copper has a tendency to be more acute (5) and pronounced (6, 7), and further it can tasted in low amounts and discolor the food (8). It can be said that water flows through Cu pipes, but soda is put in Al cans

Learn MoreStainless steel vs aluminum, which is better for CNC machining

2022. 9. 2. · The elemental composition of a material is critical to CNC machining projects, as the composition of the metal has a large impact on hardness, corrosion resistance, durability, and strength. Stainless steel is an iron alloy containing at least 10.5% chromium, and other elements include aluminum, silicon, sulfur, nickel, selenium, molybdenum, nitrogen, titanium, copper and

Learn MoreCopper Coil vs Aluminium Coil in AC : Which One is better?

The ductility of copper is better than aluminum. You can easily bend a copper tube with bare hands without breaking it, But for aluminum, there is always a chance of breaking. But the only concern for the copper tube is the weight. The density of copper is more than aluminum. So for the same design, a copper coil will be heavier than an

Learn MoreSpecialized Machining Copper Vs Aluminum manufacturer in China, Machining Copper Vs

Home > Tags > Machining Copper Vs Aluminum (Total 24 Products for Machining Copper Vs Aluminum) Machining Copper Vs Aluminum - manufacturer, factory, supplier from China. Customized Black Anodizing CNC machining Aluminum Parts. Customized CNC machining plastic parts with new style. Customized CNC machining aluminum oxide.

Learn MoreMachining: Is aluminum of the same thickness and density easier

Answer (1 of 12): Absolutely. Copper is notoriously troublesome to machine. I would describe it as a somewhat gummy material, with a tendancy to stick to tools. Aluminum is much easier to

Learn MoreMachining copper | Practical Machinist

Any suggestions or tips for machining copper? lathe and mill work. Would you treat it like aluminum for buying correct tooling?

Learn MoreRecommended machining parameters for copper and

2022. 7. 6. · 9 Ultra-precision machining of copper.. 40 9.1 Principles of ultra-precision machining.. 40 9.2 Example high-strength copper-aluminium alloys to the very soft pure

Learn More

Leave A Reply