Tips for Crusher Maintenance - Thomasnet

Jaw Crushers Check oil regularly, making sure it is free of dirt and contaminants. Check jaw dies every day, and make sure bolts are fastened securely. Maintain crusher backing to ensure proper vibration and impact protection. Keep breathers clean. Make sure the toggle area is clean, especially prior to any adjustments.

Learn More4 Types of Stone Crushers' Maintenance and Efficient Improvement

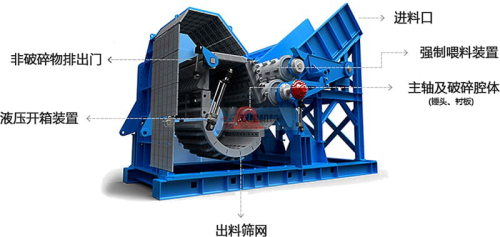

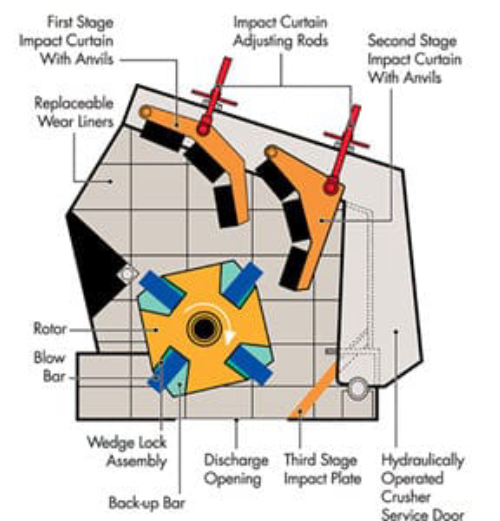

The regular maintenance and repair include adjustment of the gap between the rotor of the impact crusher and the impact lining plate, replacement of wearing parts, regular inspection of the hammer, lining plate, bearing temperature, etc. Replace badly wearing parts in time. Regularly inspect temperature of the rotor, motor and bearing, etc.

Learn MoreJaw Crusher Maintenance and Use - 428 Words | Studymode

some maintenance matters about jaw crusher to all the customers. First, the jaw crusher (jaw) lubrication 1, Before the jaw crusher started, the thrust plate and the thrust plate between the supports should be injected into the right amount of grease. 2, Notice the friction surface lubrication, and ensure the normal operation of the machine and prolong its service life. 3, The jaw crusher

Learn MoreDaily Maintenance Of Jaw Crusher - News - Hysan Road & Bridge

Daily Maintenance Of Jaw Crusher Apr 10, 1. Check the heating of the bearing. For rolling bearings, the temperature cannot exceed 70°C, and for sliding bearings, the temperature cannot exceed 60°C. If the temperature exceeds the specified temperature, stop immediately for inspection and troubleshooting. 2.

Learn MoreMaintenance of Jaw Crusher - Knowledge - Shanghai Machinery

Jaw crusher is widely used in mine, metallurgy, high way, railway and water conservancy industries, the compression strength of jaw crusher is not exceed 320 Mpa when jaw crusher designed by the specialist.. Jaw crusher wear phenomena in daily operations is inevitable, we have to do regular jaw crusher maintenance to extend the useful life to the maximum, so we should proceed long-term

Learn MoreMini Jaw Crusher | Sepor, Inc

SEPOR, INC. 718 N FRIES AVE. WILMINGTON, CA 90744. 310 830 6601. Fax: 310 830 9336 [email protected]. OPERATING AND MAINTENANCE MANUAL. MINI JAW CRUSHER

Learn MoreOperation and Maintenance of Jaw Crusher

The jaw crusher has the characteristics of large crushing ratio, high output, simple structure, uniform crushing particle size and simple operation and maintenance. The working characteristics and

Learn MoreEasy Maintence Stone Jaw Crusher

jacques crusher plant maintenance plan. C Series jaw crushers – group, has installed over 10 000 jaw crushers since the 1920s. some care.

Learn MoreHow to Maintain Mobile Crushers | For Construction Pros

When performing daily inspections on your crusher, there are several areas to examine before use, starting with the bearings. Roller bearings

Learn MoreMAINTENANCE OF JAW CRUSHER- Heavy Industry

MAINTENANCE OF JAW CRUSHER. 1. In order to guarantee normal operation of machine and prolong service life, inject lubrication oil is needed regularly. 2. About 50% to 70% of volume of all bearing housings should be filled with grease. Change the grease each 3-6 month, clean the roller bearing carefully. 3.

Learn MoreMBMMLLC.com: Jaw crusher maintenance and operation video

We wanted to make a quick and easy instruction video for our jaw crusher. Included are instructions for jaw plate removal and replacement, greasing, jaw gap

Learn MoreHow Jaw Crusher Works

our jaw crushers has the features of simple structure, reliable performance, convenient maintenance and safe use.

Learn MoreJaw crusher maintenance | Henan Deya Machinery Co., Ltd

1.5 Inspection and Maintenance. The daily inspection and maintenance of the jaw crusher are mainly as follows. (1) Check the heat of the bearings, make sure it is within the normal range indicated by Deya Machinery’s operation manual. (2) Check whether the lubrication system is working properly. (3) Check the quality of the oil return pipe.

Learn MoreCrusher maintenance tools - Outotec

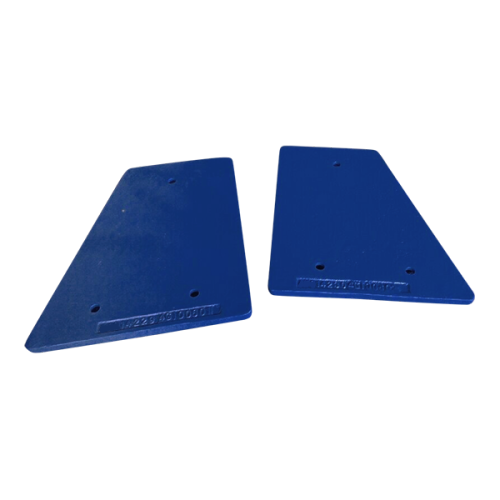

The maintenance platform is available for ® C Series™ jaw crushers with one-piece and two-piece jaw die set-ups. Its lightweight aluminum design with easy adjustability makes it easy to handle and improves working ergonomics as well as safety.

Learn MoreHow effective maintenance of jaw crusher?

Jaw crusher maintenance mainly from the following three aspects: · Before starting maintenance 1, should carefully check bearing lubrication condition is good,

Learn MoreTips of jaw crusher maintenance

While,Jaw crusher in the daily operation of wear and tear is inevitable, we have only done regular maintenance can extend the useful life to the maximum,

Learn MoreCone Crusher Maintenance Guide | Crusher Mills, Cone Crusher, Jaw Crushers

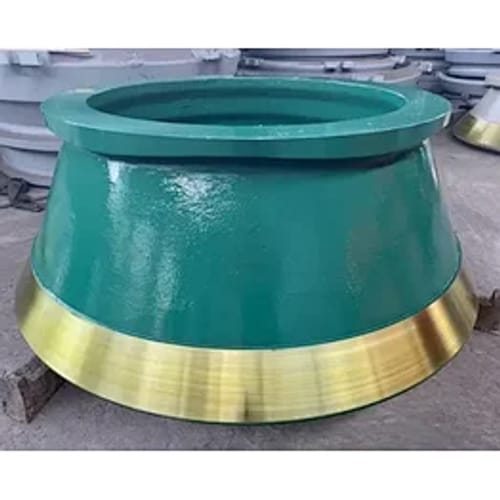

The Operation & Maintenance Manual is provided with all new jaw crushers. If this manual is lost, new copies are spring cone crusher maintenance instruction manual-crusher Are you looking for the spring cone crusher maintenance instruction manual? Email to [email protected] or consulting problem with online customer service for

Learn Moreoften replace part of jaw crusher

Jaw crusher maintenance | Henan Deya Machinery Co., Ltd. The crushing chamber jaw plates are loose, the fixing bolts are loose or broken. Stop the jaw crusher, check the fixation of jaw plates, and use hammer to tighten the wedge on plates, then fasten the bolts or replace the bolts if they are broken. 2. Toggle plate and seat generates impact

Learn MoreJaw Crusher Maintenance Management - MGS Casting

The eccentric shaft of the simple pendulum jaw crusher should be repaired when the wear is as follows: ellipticity > 0.10 ~ 0.15 mm; conicality > 0.08 ~ 0.12 ram; journal surface convexity and concavity > 0.10 ~ 0.12 ram. The repair method is: 1) According to the wear situation, lathe turning and scraping repair can be taken.

Learn More5 Tips for Jaw Crusher Operation

Jaw crusher is widely used in mining industry because of its simple structure, reliable work, convenient maintenance and low production cost.

Learn Morewhat are the maintenance of primary jaw crusher

Maintenance and Repair of Jaw Crusher | JXSC Mine.

Learn MoreHow does a Rock Crusher Work - Jaw Crusher - 911 Metallurgist

Tension springs take up bolt stretch reduce maintenance practically eliminate breakage. Swing jaw deflection plate eliminates we hub

Learn MoreMain points for maintenance of jaw crusher - News of Joyal Crusher

May 15, · Jaw crusher is an essential equipment for producing aggregate sand and gravel. It has the advantages of large crushing ratio, uniform product size, simple structure and easy maintenance. It can be divided into two types: coarse crushing and fine crushing.

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

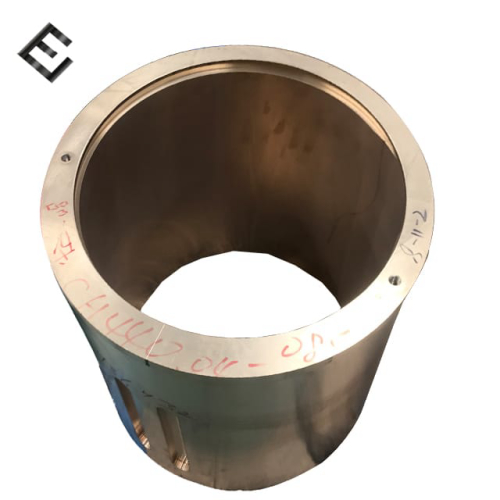

Main shaft To keep the main shaft in good lubricating situation, you need to guarantee enough geese between thrust plate.The grease added to the bearing box needs to occupy about 50% of its space and be replaced every 3-6 months. When changing the engine oil, please use clean gasoline or kerosene to clean the roller bearing raceways.

Learn MoreNews - Maintenance of C145 jaw crusher

Maintenance of C145 jaw crusher . Maintenance procedures 1. The crusher is not allowed to start with load. 2. When crushing ore, the ore must be given to 2/3 of the crushing cavity. 3. The inspection, cleaning and repair of the spindle shall not be less than once a year, and the ammeter shall be inspected once every six months. 4. Check the

Learn MoreHow to maintenance jaw crusher properly - Baichy

Feb 11, · Successful jaw crusher maintenance requires the right resources, the right tools and the right method. When an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possible. Here are main steps for jaw crusher maintenace. Firstly, Cleanliness is key.

Learn MoreRegular crusher maintenance integral to reliability

Jones advises: “Always ensure the wear parts are fastened into the machine properly. With jaw crushers, if you allow the jaw dies to move during

Learn Moremaintenance checklist for a crusher

Checklist For Daily Crusher Maintenance - Crusher USA daily maintenance check list for stone jaw crusher. daily maintenance check list for stone jaw crusher. shanghai shibang machine co. , ltd. is a hig Chat Now; crusher preventative maintenance checklist scheduled preventive maintenance checklist grinding machine.

Learn MoreJaw crusher maintenance platform from | Agg-Net

have developed a new range of maintenance platforms to help improve safety when changing wear parts in jaw crushers.

Learn MoreMaintenance Matters Needing Attention For Jaw Crusher

The maintenance work of jaw crusher needs to be carefully carried out during the operation of the equipment and during the shutdown inspection. After the equipment has problems, it should be dealt with in time, so as to ensure the long-term use of the equipment. Jaw crusher is a relatively popular mine crushing equipment, which has the

Learn MoreMaintenance of Jaw Crusher - Knowledge - Shanghai

Jaw crusher is widely used in mine, metallurgy, high way, railway and water conservancy industries, the compression strength of jaw crusher is not exceed 320 Mpa when jaw crusher designed by the specialist.. Jaw crusher wear phenomena in daily operations is inevitable, we have to do regular jaw crusher maintenance to extend the useful life to the maximum, so we

Learn More

Leave A Reply