Apron Feeders | McLanahan

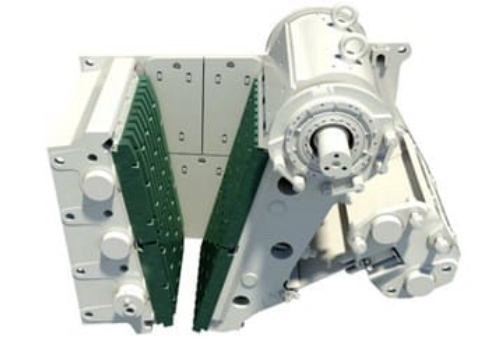

McLanahan Apron Feeders are available in six chain sizes, 16 standard flight widths and an infinite range of lengths — all designed to meet a customer's application requirement.

Learn MoreApron Feeders - AUMUND Group

These Apron Feeders are particularly well adapted to provide solutions for the conveying of moist and sticky bulk materials, such as clay, gypsum, anhydrite,

Learn MoreApron feeders - Materials Handling | Bosch Rexroth AG

When sizing feeder drives, a major factor is the necessary starting torque. High shear force increases starting torque compared to running torque, often by more than 100% on apron feeders and by at least 50-75% on belt feeders. If coarse ore and larger materials are involved, even more starting torque may be needed.

Learn MoreApron Feeder Equipment Walkthrough | McLanahan

Apron Feeders are highly effective in all types of applications, as they are great at metering material at a constant flow rate for your downstream process. They are equipped with a large machined 1045 hot rolled steel head shaft assembly featuring reversible three-piece odd tooth chain drive sprockets which are keyed and bolted to the shaft.

Learn MoreDefinition of apron feeder

A feeder in which the material is carried on an apron conveyor and in which the rate of feed is adjusted either by varying the depth of material or the

Learn MoreWhat is the preferred solution: Belt Feeder, Apron

The simple reply is: Yes, in most cases it is possible to replace apron feeders by belt feeders. Basically, the main concern is the content

Learn MoreWhat is the difference between Belt and Apron Feeders?

Apron fed machines often cost about $20,000 more than their belt fed counterparts. Belt feeders on the other hand are much better for secondary applications where smaller aggregates that will not be dropped from height are to be considered. They can move material over longer distances much more efficiently however come with the added cost of

Learn MoreApron feeder - SlideShare

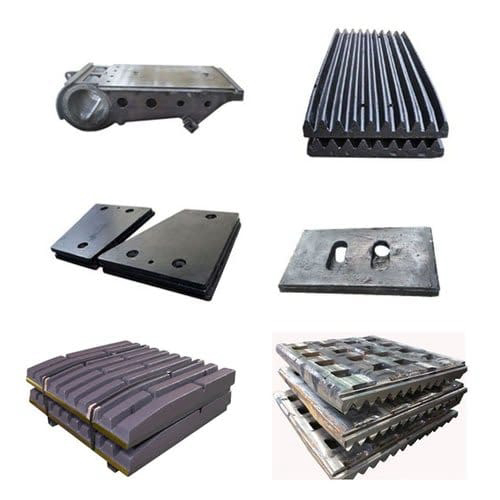

3/26 · Apron Feeders are of rugged, heavy duty construction and designed to handle feed sizes of up to 1500 mm and where no fines removal is required or where fines are removed by

Learn MoreReliability centered maintenance: apron feeders | Assetivity

Reliability Improvement. ->. Reliability Centered Maintenance (RCM) in action: apron feeders. In mining operations, apron feeders are generally located under RoM bins or underground in a dusty, hot or wet tunnel fed from a RoM stockpile, and are typically used to provide the means of moving coarse material when it first enters a processing plant.

Learn MoreWhat is 'apron feeder

2022/7/13 · An apron feeder is in fact a conveyor that is constructed from metal. It regulates the feed by carrying the ore to the delivery point at a controlled rate of speed. The face of the

Learn MoreApron Feeders vs Belt Feeders

Apron feeders are capable of extracting materials from bins, hoppers and even stockpiles. They can transfer materials across a short distance at a highly

Learn MoreApron vs. Vibrating Feeder: Pros and Cons of Each

Apron feeders are well suited for applications where large tonnages of material will be moved, and are also ideal for situations where severe impact loading is expected. These feeders are also ideal when rough or abrasive materials are being processed, such as commonly is the case with ore and rock.

Learn MoreFeeding the facts: Apron feeder basics - Outotec

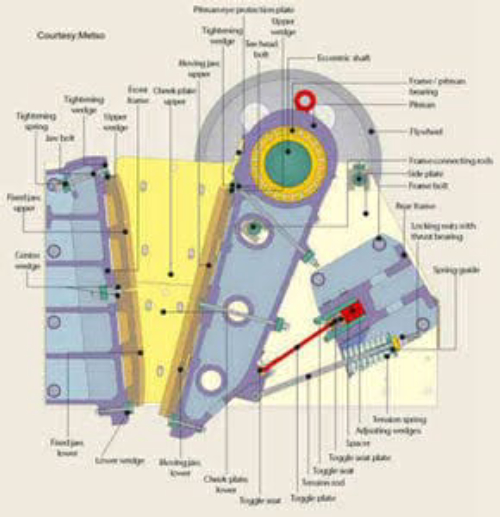

In simple terms, an apron feeder (also known as a pan feeder) is a mechanical type of feeder used in material handing operations to transfer (feed) material to other equipment or extract material (ore/rock) from storage stockpiles, bins or hoppers at a controlled rate of speed.

Learn MoreAF Heavy Duty Apron Feeder_Shenyang Powerups Machinery

What Is Apron Feeder Apron feeder is a mechanical type of feeder used in material handing operations to feed material to other equipment or extract material from storage stockpiles, bins or hoppers at a controlled rate of speed. They provides better feed control to prevent material feeding in downstream equipment from choking, absorb the shock

Learn MoreApron Feeders - MEKA Concrete Plants

An Apron Feeder is run at very low speeds and at a controlled feed rate as it absorbs the impact loads of the material falling from a dump truck or a front-end loader and is ideal for withdrawing material from under a stockpile or from under a Primary Crusher. Apron Feeders are of rugged, heavy duty construction and designed to handle large

Learn MoreExpert advice on the evolution of apron feeder design

Apron feeders are used to transport large, lumpy, abrasive and heavy ores under severe impact conditions – including wet, sticky or frozen

Learn MoreProper design of dump hoppers for apron feeders

8/2 · Figure 1 - Apron Feeder application to dump hopper and feeding primary crushing plant. Primary apron feeders are for high-capacity applications up to 10,000 tph, speed between 10 to 25 m/min

Learn MoreSteel Apron Feeders - ATMOS Handling

atmos is a recognized specialist for proof steel apron feeders / extractors. Our steel apron feeders are proven effective for the extraction of difficult

Learn MoreApron Feeders vs Belt Feeders - IEM

IEM’s Apron feeders are efficient, long lasting, and easy to maintain. IEM makes large diameter Apron feeders ranging from 900 mm – 1500 mm that are capable of providing a maximum capacity of up to 14,500 mtph. IEM provides complete solutions for weighted Belt feeder set-ups. We manufacture heavy duty belt feeders in the range of 800 mm

Learn MoreFeeding the facts: Proper sizing and selection of your apron feeder

Apron feeders are a volumetric type feeder, which means bulk density is used to determine the speed and power (torque) needed to extract a certain tonnage per hour (tph) of material. The minimum bulk density is used to determine the speed and the maximum bulk density establishes the power (torque) needed for the feeder.

Learn MoreApron Feeders, heavy duty apron feeder,Apron Feeder Manufacture, Apron

The apron feeder is a reliable feeding method for when the material to be conveyed is lumpy, abrasive, heavy, high temperature. it is a feeding solution more robust than a traditional belt feeder is required. Apron feeders are designed to feed material at a desired handling capacity to downstream equipment.

Learn MoreApron Feeders - Astec

The apron feeder is built to withstand wet, sticky or clay-like material and handle it with ease. These feeders can be installed in a horizontal position or inclined up to 15-degrees. Applications Previous Crushed Stone

Learn MoreApron Feeders - AGGRETEK heavy duty apron feeders

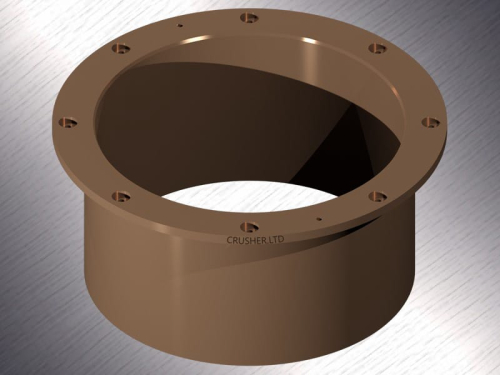

Anti-friction spherical roller bearings are fitted to the head and tail shafts and housed in heavy duty plummer blocks. Bearings are grease lubricated and a grease reservoir is included in the design of the bearing housings and end caps. The Apron Feeder has a remote mounted electrically operated automatic greasing system as standard. TAIL

Learn MoreLearn About Our Apron Pan Feeders - Williams Crusher

As one of the leading pan feeder manufacturers in the industry, all Williams Apron Pan Feeders are completely assembled in the shop and are run before shipment. Contact us today to discuss your application in detail with one of our experienced sales engineers. Call (314) 621-3348, email us at [email protected] or locate an agent near you.

Learn MoreMAF SERIES APRON FEEDERS

MEKA Apron Feeders are installed in horizontal as well as in inclined applications. Due to the special design of the aprons an inclination range up to 15 can be realized. In ad-dition the bed height of the conveyed material stays con-stant ensuring an equal

Learn MoreApron Feeder | HAF - HAZEMAG

OPERATION METHOD. The Apron Feeder is used to remove the material from a feed hopper or as an additional material conveyor unit. The Apron Feeder ensures an

Learn MoreWhat is an Apron Feeder? (with pictures) - About Mechanics

An apron feeder is a machine with a conveyor belt made of closely connected plates that's used to feed materials into equipment

Learn MoreWhat is the discharge device of apron feeder

Breaking system in the coarse breaking of the feed size is large, commonly used apron feeder feeder, apron feeder to breaker configuration a certain height difference, apron feeder using the discharge device into the breaker, the design angle is usually 50-60 °, due to the large height difference, angle inclination, the impact of the fall of the apron feeder to its discharge device is large

Learn MoreApron feeder basics

In simple terms, an apron feeder (also known as a pan feeder) is a mechanical type of feeder used in material handing operations to transfer (

Learn MoreApron Feeders – Processing Technology - FAM

FAM designed apron feeders are generally used to remove material from under hoppers, which are typically built from steel or concrete and sit directly above

Learn MoreApron Feeder High-strength, heavy-duty productive processing

As an interface between mining trucks and the processing system,. Apron Feeders provide steady, controlled feed for downstream processing – improving production

Learn More

Leave A Reply