Gyratory Crusher Feed Size

Maximum feed size (mm) Typical maximum product size (mm) Typical capacities (t/h) Gyratory crusher: Primary: 1500: 200-300: 1200-over 5000: Jaw crusher: Primary: 1400: 200-300: Up to 1600: Horizontal impact crusher: Primary/secondary: 1300: 200-300: Up to 1800: Cone crusher: Secondary 450 60-80Up to 1200: Cone crusher

Learn Moregyratory crusher working G10SEC V-BELT PULLEY SPC 530/8, ECCENTRIC

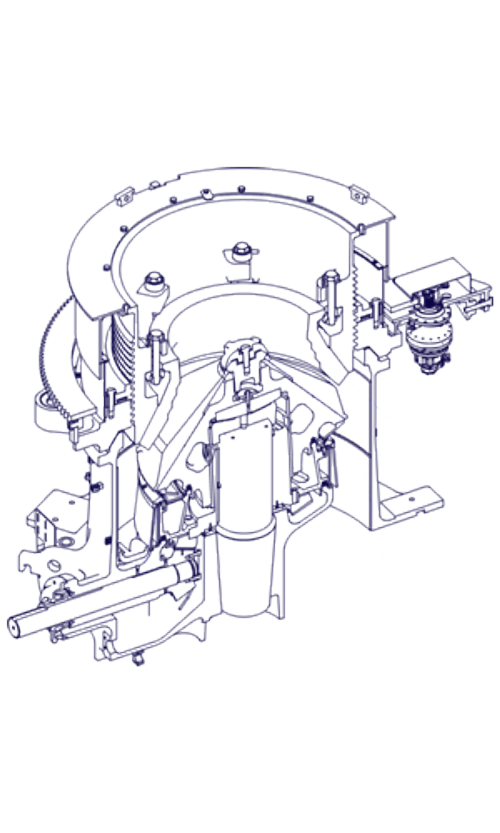

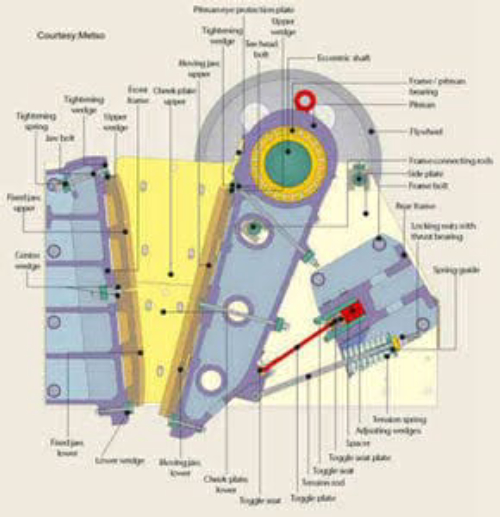

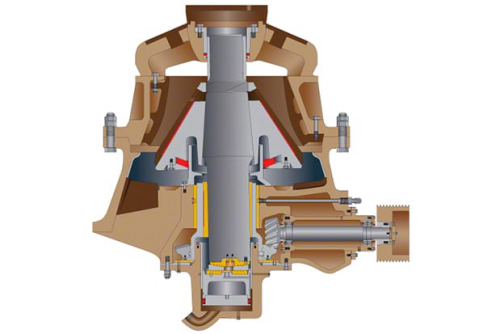

Since the late 1800s, the size of crushers has greatly increased, but the engineering principles that make them work have remained the same. wikipedia of gyratory crusher construction working. Gyratory crushers work on the same principle as cone crushers (Figure 4.4(c)). These have a gyratory motion driven by an eccentric wheel.

Learn MoreGyratory crushers - thyssenkrupp

thyssenkrupp gyratory crushers in primary crushing thyssenkrupp, range of gyratory crushers product size required, optimizing proven technology.

Learn MoreTypes of Crushers: What You Need to Know

After materials receive their first round of crushing, they are fed into a secondary crusher to be reduced further. Average material sizes range from 350mm to

Learn MoreGyratory Crusher Feed Size - This Week in Fedora

Industrial Solutions Gyratory crushers. They depend on the feed characteristics and the crusher configuration. The feed material should be at least 20 smaller than the width of the feed open - ing. Arrangement drawing with fitting dimensions and loads on request. Large feed opening 3,080 x 1,675 mm Jaw gyratory crusher.

Learn MorePDF 2. Gyratory CrushersPDF

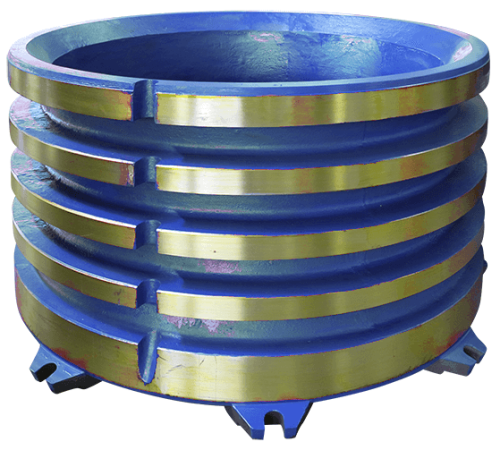

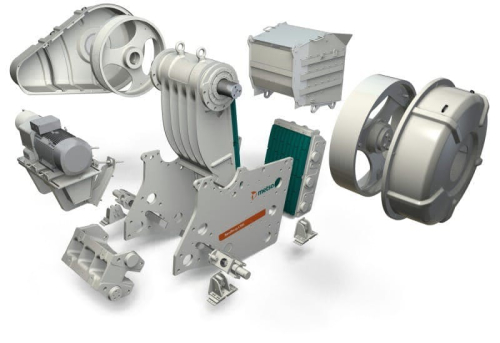

Mechanical Features General The majority of gyratory crushers that are currently manufactured are large units, i.e., 42 in. and larger gape, and are of the short shaft type. Generally the units are of the hydraulic supported type although there are specific applications where the spider suspended type is more desirable.

Learn Morejaw crusher and gyratory crusher | Henan Deya Machinery Co., Ltd

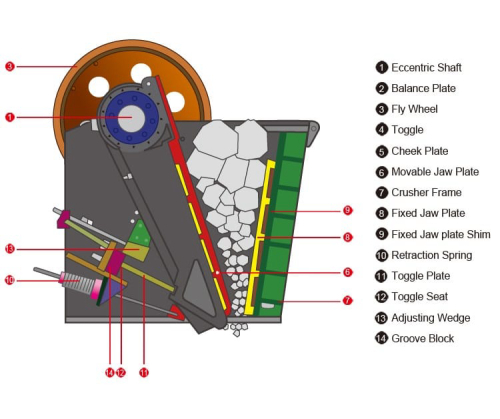

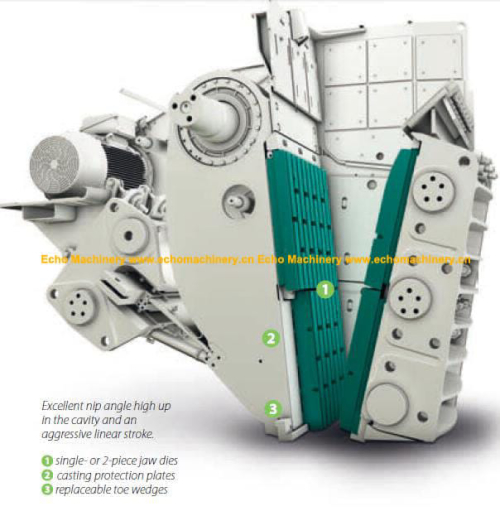

7/29 · A Jaw Crusher reduces large rocks by dropping them into a flat “V” shaped space created between a fixed surface and a movable surface. The compression is created by forcing the rock against the stationary plate. The opening at the bottom of the jaw plates is the crusher product size gap. The rocks remain in the jaws until it is small enough

Learn MoreGyratory Crushers - Makuri

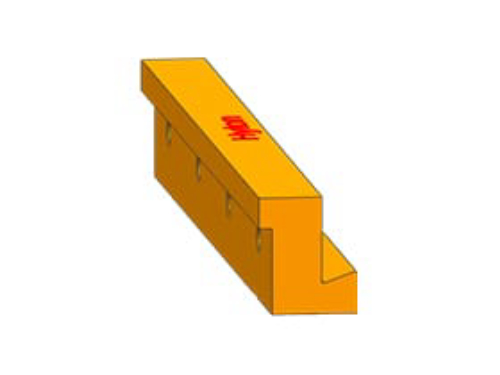

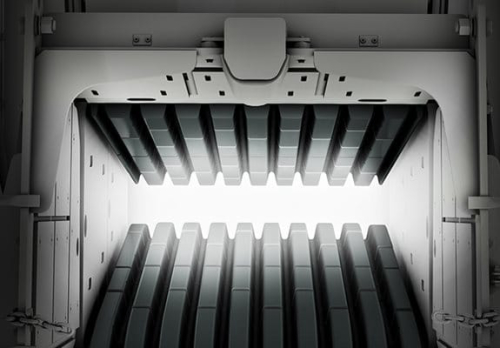

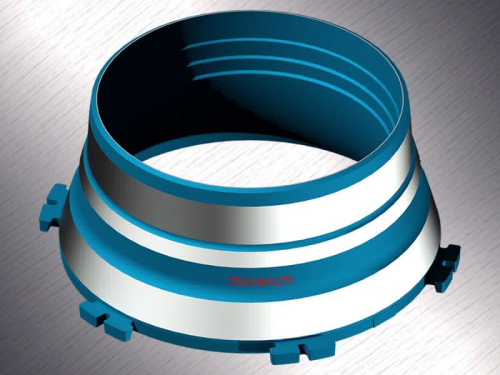

Proper design of both gyratory crusher mantle and concave liners leads to lower and more consistent crushed product size, better throughput, highly predictable liner changeout intervals and overall better asset utilisation. Previous Next Concaves Previous Next

Learn MoreGyratory Crusher Sizes Manufacture and Gyratory Crusher Sizes

China Gyratory Crusher Sizes Manufacture, Visit Here to Find the Gyratory Crusher Sizes That You are Searching for. Shenyang Sanland Mining Equipment Manufacture Co., Ltd. [Liaoning,China] Business Type: Manufacturer Main Markets: Africa , Americas

Learn MoreCrusher - Wikipedia

A gyratory crusher is one of the main types of primary crushers in a Gyratory crushers are designated in size either by the gape

Learn Moresizes of gyratory crusher and capacity

Capacity Of The Gyratory Crusher dukeprospectivehealth.org. capacity of gyratory crusher and size pdf.capacity of gyratory crusher and size pdf Gyratory Crusher shape of two cones

Learn MorePDF Industrial Solutions Gyratory crushers - ThyssenKruppPDF

Gyratory crusher Throughput [t/h] with open side setting OSS [mm] 5) Type 130 150 170 185 200 215 240 270 300 [inch] min . max. min . max. min . max. min . max. min . max. min . max. min . max. min . max. min . max.

Learn More1 Crushing - Springer

Gyratory crushers-Typical installations. Crusher. Material. Product. Manufacturers. Plant and location size crushed hp size.

Learn MoreAMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding circuit.

Learn MoreGyratory VS Jaw Crushers: Advantages & Disadvantages

Large receiving opening per dollar of investment. Shape of receiving opening favourable for blocky feed. This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation. The jaw crusher is more easily adjusted, to compensate for wear of liners.

Learn MoreHow do you size a gyratory crusher?

Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model. Primary impact crushers are generally used in nonabrasive applications and where the production of fines is not a problem. Of all primary crushers, the impactor is the crusher that gives the best cubical product.

Learn MoreGyratory Crusher Wear Plates

60 x 89; 60 x 113NT/UD. The option to customise. We provide tailored solutions for any model and size of equipment that may

Learn MoreDifference Between Jaw Crusher and Gyratory Crusher

The request of input particle size of the jaw crusher is strict. After blasting, it is necessary to impact and crush the big stone to meet the requirement of

Learn MoreGyratory Crusher | Hazemag North America

GYRATORY CRUSHER | Throughput Capacity ; Crusher Size, Eccentric Throw (in.) · 4.5″, 5″, 5.5″ ; 42 - 65, 1" 1.25" 1.5", 915 1069 1234, 1031 1223 1400, 1157 1355

Learn MoreGyratory Crusher. 시장 2022 최신 개발, 동향 및 수요, 크기, 공유, 성장, 동향 및 예측, 2028

글로벌 Gyratory Crusher. 시장 2022-2028 보고서는 수익, 거래량, 규모, 가치 및 이러한 귀중한 데이터를 다룹니다. Gyratory Crusher. 시장 보고서는 수많은 다른 시장 관련 기본 요소를 포함하는 체계적인 시장 조사 보고서를 통해 Gyratory Crusher. 시장의 기회에 대한

Learn MoreGyratory Crusher & Cone Crusher Mantle Differences

This is due to the angle that the main shaft is on. The greater angle of the cone crusher puts the pivot point below the distributor plate. While the pivot point for the gyratory crusher is at the spider cap. This difference in the pattern of gyration has a purpose. The primary crusher produces a product that is gauged by the size of the open

Learn MoreSizes Of Gyratory Crusher And Capacity

Gyratory Crusher Size. Size Reduction Equipment . 2018-11-15 Crusher Feed Size Product Size Capacity (ton/hr) Power Requirement Jaw Crusher 1.8 m 250 mm 1200 High Gyratory Crusher Same Same 4500 High Smooth Roll Crusher 12-75 mm 12-1 mm 350 Low Tooth Roll Crusher 500 mm Same 500 Low.

Learn MoreGyratory Crushers | Diamond Equipment Group

Diamond supplies Trio Gyratory Crushers. These crushers are a proven first stage of compression crushing for Large Mines and Quarries. Mined ore or quarried rock can processed down to a size suitable for the secondary crushers. Trio ® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology

Learn MoreWhat is a Gyratory Crusher | Quarrying & Aggregates

It can directly feed materials to the gyratory crusher by multiple vehicles, so the production capacity is large (1500-9000 t/h), the unit energy consumption is small, and the work is stable. The noise is small. The crushed stone has uniform particle size and relatively few flakes. The disadvantages of the gyratory crusher are also obvious:

Learn MoreCrushing equipment - UZTM-KARTEX

The crushers are designed for reliable operation in different climatic conditions Max. lump size of feed, mm Primary and reduction gyratory crushers.

Learn MoreGyratory Crusher Sizes Manufacture and Gyratory Crusher Sizes Supplier

China Gyratory Crusher Sizes Manufacture, Visit Here to Find the Gyratory Crusher Sizes That You are Searching for. Company Details. Shenyang Sanland Mining Equipment Manufacture Co., Ltd. [Liaoning,China] Business Type: Manufacturer;

Learn MorePDF) Modelling the crushing-sizing procedure of industrial gyratory crushers

2006/10/9 · Tsakalakis, K.G., 1990, Product Size Distributions of Industrial Gyratory Crushers, Mining and Metallurgical Annals, Vol. 75, pp.41-48, (in Greek with English abstract). Mineral Processing

Learn MoreIndustrial Solutions Gyratory crushers - ThyssenKrupp

coarsely crushed material is then reduced to the desired product size in the crush - ing chamber below. Jaw gyratory crushers can handle much bigger chunks of material than comparable

Learn MoreAllis Chalmers Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

ALLIS CHALMERS - Gyratory Crusher - Mining Surplus | New and 1 - ALLIS CHALMERS 60in x 89in Gyratory Crusher, S/N 2-1724-97452. No motor. Maximum feed size is 48in.

Learn MoreGyratory Crusher Pro - thyssenkrupp Mining Technologies

Gyratory Crusher KB 63-89 for iron ore. Capacity: 6,200 t/h · Cyclo-palloid spiral bevel gear · Higher-capacity drive motors if required · Rugged

Learn More

Leave A Reply