Gyratory crusher lubrication and filtration - Crushing

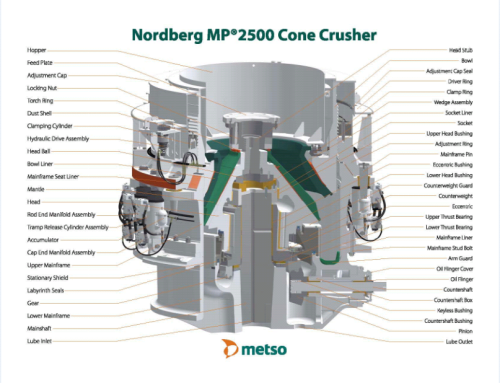

The lubrication system is comprised of an oil reservoir, pumps, heat exchanger, and protective instrumentation. Its function is to lubricate and cool the

Learn MoreSUPERIOR® gyratory crushers

SUPERIOR gyratory crusher features 1 Crushing chambers are matched to each individual application, The entire lubrication system is controlled, including the air blower, immersion

Learn Moregyratory crusher working G10SEC V-BELT PULLEY SPC 530/8, ECCENTRIC

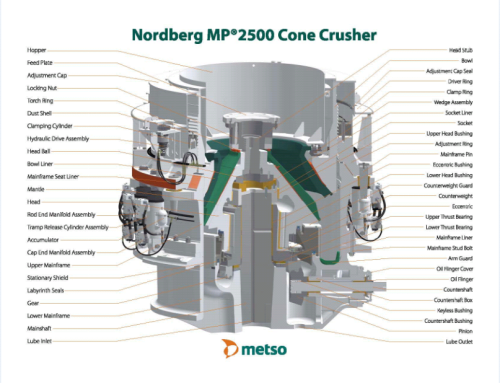

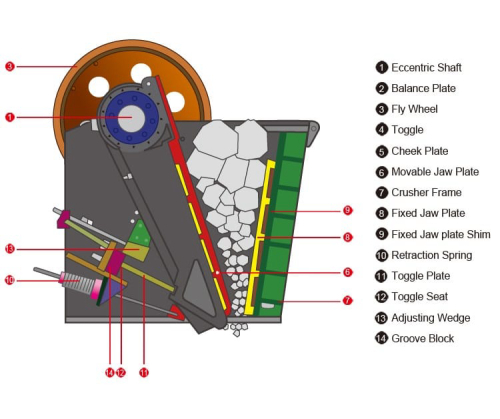

Gyratory crushers work on the same principle as cone crushers (Figure 4.4(c)). These have a gyratory motion driven by an eccentric wheel. gyratory crusher lube system working. Gyratory Crusher Lube System Gyratory Crusher Animation gyratory crusher working animation Oct 17 working animation of gyratory crusher

Learn Moregyratory crusher for lube system

Gyratory Crusher Lubrication The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher isn’t as readily exposed to. This crusher, because it may be loaded from two sides, often is used in an open pit situation where large ore

Learn MoreUS2628788A - Gyratory crusher - Google Patents

B02C2/045 Crushing or disintegrating by gyratory or cone crushers An added object is to provide an improved lubrication system for acrusher of the

Learn MoreGP300 MAIN SHAFT GP300 | gyratory crusher lube system

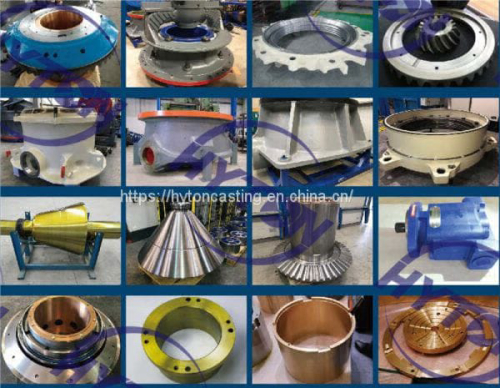

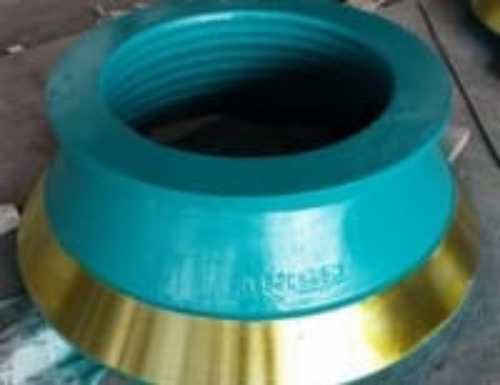

What is High Manganese Steel Cone Crusher Wear Parts Suit. Check out the new High Manganese Steel Cone Crusher Wear Parts Suit Gp300 Main Shaft Assy from Jiangsu Hyton Mechanical Equipment Co., Ltd.. Here are multi-dimension videos for your reference such as product videos and company videos.

Learn MoreGrease Lubricating System Used in Different Types of

10/23 · Before understanding which lubrication system is good for crusher bearing lubrication, we need to understand the application & crusher working principle.What is

Learn MoreIntroduce The Lubrication System of Gyratory Crusher

Pastebin.com is the number one paste tool since 2002. Pastebin is a website where you can store text online for a set period of time. A self-contained lubricating system of gyratory crusher for operatively lubricating the mounting mechanism and the drive train

Learn MoreGyratory Crusher Explained - saVRee

Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly referred to as a ‘Gate’s crushers’ in the early years). A primary

Learn MoreFive steps to optimize crusher's lubrication system

Five steps to optimum performance of your crusher's lubrication system · 1. Monitoring of lube oil temperature · 2. Monitoring of lube oil

Learn MoreGlobal Mining Review - Lubricants for Compression Crushers

Gyratory crushers utilise oil lubrication to perform several functions. The oil is drawn from a common remote reservoir and serves two circuits.

Learn MoreCRUSHER SPIDER BUSHING LUBRICANT

Phillips 66® Crusher Spider Bushing Lubricant is a viscous, semi-fluid lubricant Spider bushings of gyratory crushers used in aggregate mining

Learn Morelubrication system of cone crusher slideshare

Gyratory Crusher Lube System YouTube. Feb 08, · The lubrication system is comprised of an oil reservoir, pumps, heat exchanger, and protective instrumentation. Its function is to lubricate and cool the crusher moving parts and keep them clean The lubrication of Gyratory crushers may be one of the special problems that the Jaw crusher

Learn MoreHP500 SPLIT FLANGE 1A32FLB32 | gyratory crusher lube system

PF impact crusher read more It can crush all kinds of coarse, medium and fine materials (granite, limestone, concrete, etc.) with a feed particle size not exceeding 500mm and a compressive strength not exceeding 350MPa. , Energy, cement, chemical, construction and other industries

Learn MoreInstruction Manual for Gyratory Crusher PXZ-1500II

1 Section 1 Safe Operation of Equipment 1.1 Introduction The gyratory crusher of CITIC Heavy Machinery company is mainly used in mines, quarries, metallurgy and other fields. During its process of design and manufacturing, we take full account of the influence

Learn MorePrimary Crusher, Gear, Fuller-Traylor Gyratory Crusher, Lube Oil

The continuously operation of the CJC™ HDU 427/108 kept the con- tamination out of the oil system. This led to increased oil lifetime and

Learn MoreGyratory crusher upgrades - Outotec

Outotec has developed five upgrade options that not only minimize wear but also help to ensure a long and productive life for your crusher and its key components. View them below.

Learn MoreFive steps to optimize crusher's lubrication system - Outotec

1. Monitoring of lube oil temperature A lot can be learned about a cone crusher by simply watching the supply oil temperature and comparing it to the return oil temperature. Return oil temperature should be in the range of 60~140ºF (15~60ºC), although ideally in the range of 100~130ºF (38~54ºC).

Learn MoreGyratory crushers - Industrial Solutions CIS

The design of our gyratory crushers and jaw gyratory crushers is based on over When it comes to the crunch, crushing systems from thyssenkrupp.

Learn MoreGrease Lubricating System Used in Different Types of Stone Crusher

Normally, operating an oil-lubricated crusher with contaminated lubricating oil (old, dirty oil) is a common mistake followed by maintenance people. As a thumb rule, operators should use gear lubricants added with extreme pressure additive with a minimum oil viscosity of 22 CST at the bearing operating temperature.

Learn MoreCG850 Primary Gyratory Crusher With Large Feed Opening

The Tank Instrument Monitoring System (TIMS) provides real-time monitoring of the crusher lubrication system to ensure it functions optimally. Monitoring the Lubrication system, spider bearing grease system and overpressure system, it ensures oils are at the right flow and temperature, and triggers alarms to protect the crusher. Avantages

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

5.1 Introduction. Gyratory crushers were invented by Charles Brown in 1877 and developed by Gates around 1881 and were referred to as a Gates crusher [1]. The smaller form is described

Learn MoreCrusher | IQ Oil Australia

Crusher ; Client: BHP Billiton Iron Ore ; System: Crusher Lube Tanks, Gearbox Primary & Secondary, Gyratory Crusher. ; Oil: 2000L ISO 150 ; ISO Prior to CJC®: 24/22

Learn MoreGyratory Crushers - SolidsWiki

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone thin oil lubrication system components etc.

Learn Moregyratory crusher | bushing grinding mills

systems and alamrs on gyratory crusher. Gyratory Crusher Lube System YouTube. systems with tank-mounted oil pumps allow oil to be circulated before crusher startup to provide pre-lubrication of the crusher internal components. Gyratory crushers were invented by Charles Brown in 1877 and further developed by Gates in 1881 (they were commonly

Learn MoreCone Crusher Lube Systems

Lubrication System of Cone Crusher in Operation - Digital In the operation of a cone crusher, it will generate friction between the mutual contact surfaces and surfaces with relative motion, it consume energy for overcoming cone crusher lubrication system Strongly recommend you to contact with us through online service!

Learn MoreGyratory Crushers - Mineral Processing & Metallurgy

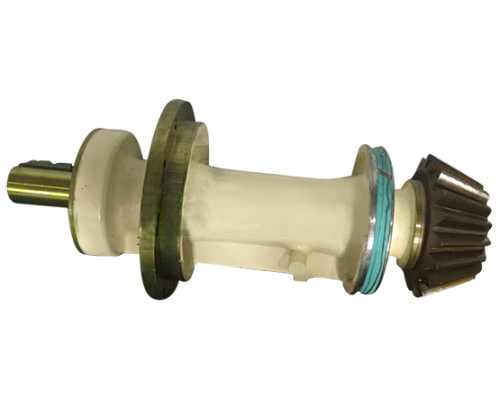

PINIONSHAFT ASSEMBLY for a 42-65 Gyratory crusher. Spiral bevel pinion mounted on turned steel shaft in cast steel housing. Anti-friction bearings. Assembly is independently lubricated. Seal plates and oil seals on both ends of housing. Spiral bevel gears allow a broad range of speeds. Eccentricity Adjustable to Capacity Demands

Learn MoreCrusher Maintenance - Cooper Fluid Systems

A circulating lubrication system keeps the bearings, Cut open model of a Gyratory Crusher illustrafing all moving parts.

Learn MoreCG800i Gyratory Crushers — SRP

Our Tank Instrument Monitoring System (TIMS) provides real-time monitoring of the crusher lubrication system to ensure it functions optimally. Monitoring the Lubrication system, spider bearing grease system and overpressure system, it ensures oils are at the right flow and temperature, and triggers alarms to protect the crusher.

Learn MoreGyratory crusher having self-contained lubrication system

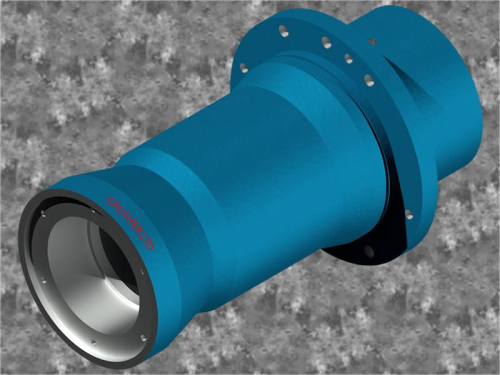

A gyratory crusher for crushing material having a frame mechanism including a lower frame portion; a crusher head having a bottom surface;

Learn MoreCone Crusher Lube Systems | Crusher Mills, Cone Crusher, Jaw

New Cone Crusher Products » Cone Crusher Enhancement Products. We offer following new products to enhance your CS cone crushers: 4 ¼' Cone Crusher. Turbocharge Kit; . Lube

Learn More

Leave A Reply