Clinker Cooler - Emphor IPS

The clinker temperature is the main constraint for the measurement. With the SICKBulksckan product, it’s possible to control the clinker flow thickness independently of the gas

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant Equipment

Cooling clinker The clinker temperature is an important indicator of the grate cooler performance, which reflects the cooling efficiency of the grate cooler, and also creates conditions for the conveyer, storage, and cement grinding of clinker in subsequent processes.

Learn MoreWP9 Oxyfuel clinker cooler prototype - SINTEF

Clinker cooling is an essential step in the cement clinker manufacturing process, as it influences the product quality as well as the energy efficiency of

Learn MoreGrate Cooler in Cement Plant

AGICO supplies grate coolers for cement clinker production. The clinker coolers we offer are the most advanced reciprocating grate coolers, which are widely

Learn MoreClinker cooler | Lechler

10/29 · Gas cooling Clinker cooler Clinker cooler System-optimizing, -protecting and efficiency-enhancing cooling. Following capacity increases, cooling with air alone is often no longer sufficient to achieve the proper operating conditions of the downstream filter. Injecting water into the clinker cooler provides a remedy here.

Learn MoreClaudius Peters Clinker Cooling Technology | Claudius

Clinker Coolers When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process. A maximum of the amount of heat extracted from the

Learn MoreClinker Coolers - Everything for cement

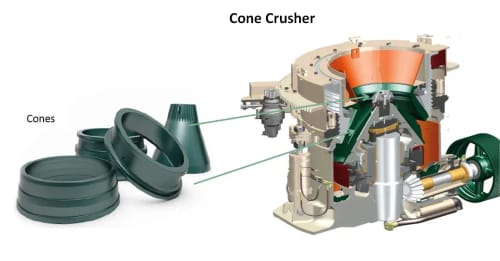

Clinker Coolers. In cement manufacturing, formation of clinker nodules occurs at the entrance to the hottest part of the kiln with a material temperature of around 1280°C. The clinker is preferably in the form of 10-mm to 25-mm size nodules that exit from the front end of the kiln into the cooler.

Learn MoreClinker cooler - Lechler

Injecting water into the clinker cooler provides a remedy here. The cooling of the gas also causes the gas volume to reduce and protects

Learn MoreMartin Engineering

Rethinking Clinker Cooler Buildup. The Sustainability Commitments 2030 program aims to make HeidelbergCement an industry leader in workplace safety. Lehigh-Hanson's expectations for a proposed solution required the system to: · Be highly reliable and accessible. · Eliminate material buildup within the cooler.

Learn MoreClinker Grate Cooler for Cement Plant

Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plant. Its main function is to cool and transport the cement clinker. At the same time, it provides hot air for the rotary kiln and the decomposition furnace, which is the heat recovery of the firing system. The main equipment.

Learn MoreRotary Cooler | Clinker Cooler In Cement Plant | AGICO CEMENT

High thermal efficiency: the rotary cooler can put all the air after cooling material into the kiln as the secondary circulating air, which improves the thermal efficiency of the kiln.; High quality of clinker: the clinker from the rotary kiln (1000-1200℃) is rotated by the cylinder to drive sufficient heat exchange between the material and the air so that the material can be cooled to below

Learn MoreClaudius Peters Clinker Cooling Technology | Claudius Peters

Clinker Coolers When producing cement, the clinker cooler plays a decisive role downstream of the clinker production pyro process. A maximum of the amount of heat extracted from the clinker during the cooling process should be retained in the overall process –

Learn MoreCement Cooler - Clinker Cooler | Types Of Clinker Cooler AGICO

Clinker enters from one end and is lifted and scattered by flights. At the same time, the cold air enters from the other end and contacts with the clinker countercurrent for heat exchange. The rotary cooler is generally arranged under the rotary kiln, with a diameter of 2-5m and a length of 20-50m. Grate cooler Grate cooler is a quench type cooler.

Learn MoreLevel measurement for cement clinker coolers

Clinker level in the cooling system. Level measurement at cement clinker cooler. The clinker is cooled as it is discharged from the rotary kiln onto

Learn MoreClinker Cooler - AGICO Cement Plant

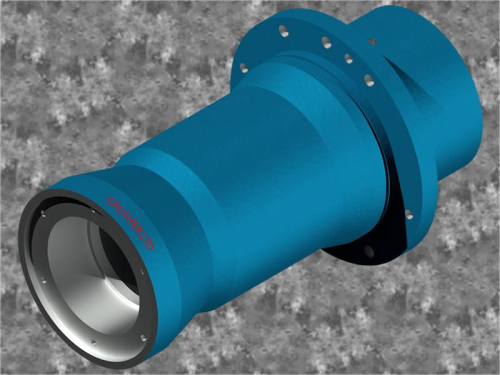

The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker production. The clinker cooler is mainly used

Learn MoreClinker Cooler - AMETEK Land

Clinker Cooler. The hot clinker produced by the rotary kiln is transferred to a grate cooler, where it is cooled by air blowers before being taken by conveyor

Learn MoreLatest trends in clinker cooling - ZKG Cement Lime Gypsum

It discusses the important parameters determining the efficiency of a clinker cooler and shows how the solutions and market shares of the individual plant

Learn MoreClaudius Peters Clinker Cooling Technology

After 50 years of experience with conventional grate coolers Claudius Peters developed a modern and future-oriented machine to overcome all disadvantages of

Learn MoreClinker cooler - SICK

Clinker cooler. Monitoring the cooling air flow. Application. Monitoring the cooling air flow · Temperature monitoring at bearings. Application.

Learn MoreClinker Cooler - Cement Cooler | AGICO Cooler In Cement Plant

As the supporting equipment of cement rotary kiln, clinker cooler (also called cement cooler) is a kind of heat exchange device that transfers heat from high-temperature clinker to low

Learn MoreTemperature control during clinker cooling process

In the clinker cooler, the hot clinker is rapidly cooled by air in order to obtain a high degree of efficiency. Modern clinker coolers have an air flow

Learn MoreClinker Cooler, Cement Cooler, Grate Cooler | Clinker

The clinker cooler, also known as grate cooler or cement cooler, it is a necessary equipment of cement clinker production. The clinker cooler is mainly used to cool and transport the cement

Learn MoreClinker Cooler - Clinker Crusher - World Cement Market - FONS Technology

The clinker parts discharged from the cooler are crushed by the way of rollers which are rotated opposite directions from each other. LEARN MORE. Kilnhood. The kilnhood is the part thatprovide connection between the cooler and the kiln. It is designed according to parameters such as cooler capacity, tertiary duct output and gas speed.

Learn More7-Eleven hiring Cooler Stocker in Hillsboro, Oregon, United States

Perform cashier duties (ring sales and maintain cash control) Perform all regular cleaning activities, and other tasks included in your job assignments. Forecast, order and stock merchandise (with

Learn MoreClinker cooler - level and pressure measurement | VEGA

To produce cement, the raw meal is burned to clinker in a long rotary kiln. After leaving the rotary kiln, the clinker has a temperature of up to +1300 °C and must be cooled down to a temperature of about +200 °C for further storage. To achieve this, the clinker bed is cooled with a continuous stream of air.

Learn MoreClinker Cooler - Home

8/5 · Reviews Photos Groups About See all Being kiln is the heart of Cement plant, Clinker cooler is the heart of the Kiln. Knowing about clinker cooler design is vital to make your plant green! 140 people like this 139 people follow this https://clinkercooler.wordpress.com/ [email protected] Product/service

Learn MoreImpact of clinker coolers on downstream equipment

Clinker coolers in today's cement pyroprocessing lines are considered to be very reliable even under kiln upset conditions. But what is the interaction of

Learn MoreClinker Cooler Refractories | Casting or Gunning | Resco Products

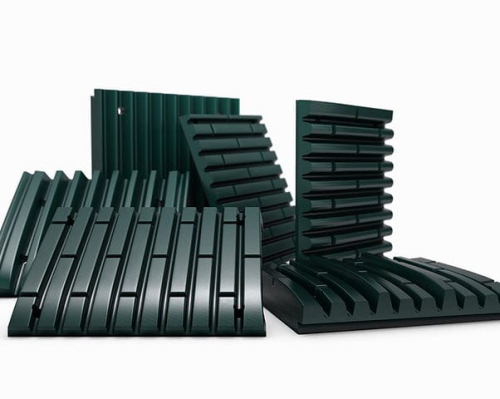

Typical clinker cooler products include the QuikTurn 60PC for casting applications and the QuikTurn 60G for gunning areas such as the tertiary air duct outlet. For the most severe abrasion, select the R-Max PC QT or the R-Max G QT. For further cement questions or assistance, contact Resco Products. RELATED PRODUCTS Alumex P-85-HS PDS SDS

Learn MoreClinker cooler – level and pressure measurement | VEGA

To produce cement, the raw meal is burned to clinker in a long rotary kiln. After leaving the rotary kiln, the clinker has a temperature of up to +1300 °C and must be cooled down to a

Learn Moreclinker cooler balance - [PDF Document

As shown in Fig. 1, high temperature clinker get into grate cooler from rotary kiln. Clinker layermoves slowly on grate bed. Cooling air blows into the clinker layer vertically from the bottom ofthe clinker, permeates and diuses in the clinker to cool the red-hot clinker. Cooling air becomeshot air after exchanging heat energy with clinker.

Learn MoreClinker grate cooler - SlideShare

6/23 · This presentation shows the principles of working of clinker coolers and gives some examples for clinker cooler modifications. emad sabri Follow General Maintenance Manager 1. Specific Surface Specificenergyrequirementof grindabilitytester 2. Types of Grate Coolers A)Traveling grate cooler 3. B) Reciprocating grate cooler 4.

Learn More

Leave A Reply