Advanced Wire Bonding

Wire Bond Loop Types · The capillary moves up and towards the second bond site. · The capillary is moved away from the second bond site before it reaches the

Learn MoreWire bonding capillary vibration behaviour through Laser

This study focus on five different capillaries with same tip design, namely of three standard design capillaries with different main taper angle (MTA) and two

Learn MoreCapillaries - wire bonding tools

Wire diameter is a key factor in determining the appropriate hole size of the capillary. An optimal hole size is essential for a successful

Learn MoreWire Bond tools and accessories - Bonding Source

The Bonding Source wire bond tool selection is focused on serving low to mid-volume assembly organizations. All of our tools are in stock and ready to ship. The tools cover a good portion of bonding applications for microelectronics and RF/Microwave assembly. Bonding Source stocks bonding tools to match all of the wire and ribbon types we sell.

Learn MoreInfluence of capillary trace on the wire bond loop profile | IEEE

The loop profile significantly influences the reliability of wire bonding, and it is necessary to study the wire bond looping process. The loop profile of the bonding wire is determined by the tension and material property of bonding wire as well as the trace and structure of capillary, in which the capillary trace has a major impact on the

Learn MoreComparison of actual bonding responses for Capillaries A and B

It is also found that the created wire bonds that used granular capillary has a good bondability and reliability. These findings are based on the evaluation of

Learn MoreTwo-step high bottleneck type capillary for wire bonding device

A two-step high bottleneck type capillary for a wire bonding device having a height of 1.5˜5.0 mm and taper of 10˜15° from the capillary end is disclosed.

Learn MoreWire Bonding Capillary (Capillaries) Market Size, Analytical

26/10/ · 9.3 Wire Bonding Capillary (Capillaries) Customers 10 Market Dynamics 10.1 Market Trends 10.2 Opportunities and Drivers 10.3 Challenges 10.4 Porter's Five Forces Analysis 11 Production and Supply

Learn MoreWire Bonding Considerations | Semiconductor Digest

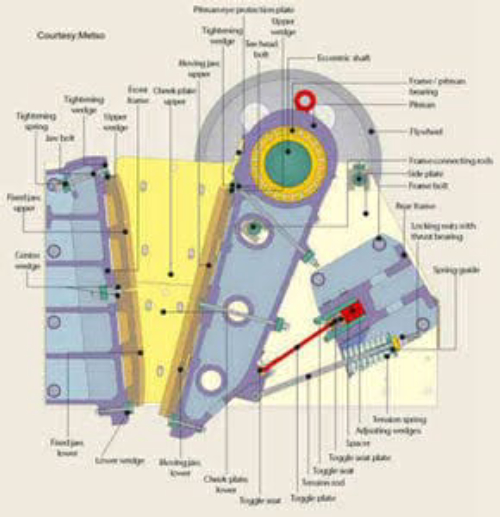

Wire bonding ranks among popular and dominant interconnect technologies due to its reputation for versatility, performance, and reliability. In this type of bonding, the capillary does not contact the pad surface. For the second half of the bond, the capillary is moved to the location for the stitch bond. Here, the capillary rests against

Learn MoreInvestigation of ultrasonic vibrations of wire-bonding capillaries

The situation can be improved by incorporating the laser vibrometer as a monitoring system to study the ultrasonic displacement of the capillary during wire bonding. Optimization of a 60-μm-BPP process was performed on an ESEC wire bonder, and the defined process window was bond power=8.4-10% and bond force=140-170 mN.

Learn MorePDF Bonding Evolution - Electron MecPDF

finishing process of ultra-fine pitch wire bonding capillaries. Presently, the packaging technology has reached the sub-50 micron bond pad pitch(BPP) device level in a production mode. The face-up wire bonding method has been the mainstream for bonding bare IC like SOP and QFP lead frames.

Learn MoreBonding Capillaries - SPT Roth Ltd

Bonding Capillaries for standard and ultra-fine pitch thermosonic gold, copper and silver alloy wire bonding. SPT offers a wide range of bonding capillaries with designs and features

Learn MoreCopper Wire Bonding Capillaries (SU Series) - Epak Electronics

Copper Wire Bonding Capillaries (SU Series) The history of copper wire bonding packaging interconnect can be traced back to the eighties, spurred then as an alternative to the costly gold. And for decades, SPT has been a leading supplier for numerous customers bonding with large copper wire diameters.

Learn MoreK&S - TeraCap - KNS

capillary solution for advanced memory & logic devices TeraCap™ is the latest capillary series for advanced memory and logic devices packaging using either gold or silve wire. TeraCap™ Major Benefits: Excellent bonding and looping consistency (yield) Superior workability (MTBA - more bonds per hour) Extended durability (more bonds per capillary)

Learn MoreWire Bond Capillary | Ball Bonding Capillaries by Kulicke and Soffa

Many designs available ex-stock. Kulicke and Soffa (K&S) is the world’s leading manufacturer of advanced wire bond capillary tools for a broad range of applications from standard to ultra-fine

Learn MoreBonding Evolution - Electron Mec

58 Capillary Wire Bonding Tools Requirement Checklist 59 EFO Wand Requirement Checklist 60 Heater Block Requirement Checklist All dimensions are in µm/inch unless otherwise stated. We reserve the right to make changes to design or specifications

Learn MoreChoosing capillaries for fine pitch bonding - Document - Gale

Combining these complex loop shapes with smaller, finer-pitch wire bonds requires the use of smaller-diameter wire [2] and bottlenecked capillaries with smaller

Learn MoreQFN Wire Bonding Capillaries from SPT (Small Precision Tools

SQ capillary coupled with optimized bonding parameters, has proven to deliver an increase in the capillary tool life as lower bond force (BF) is utilized to bond the QFN package. Proven Reliability. Whether on gold or copper wire, the SQ capillary is designed to enhance the formation of larger & width stitch bond that will effectively increase

Learn MoreWhat is the Wire Bond Process - Oricus Semicon Solutions

Thermosonic Wire Bonding is performed using ultrasonic energy, pressure, and heat to bond a wire to the surface of a substrate. In this process, the capillary is not heated and the temperature of the substrate is maintained between 100 to 150 degrees. A burst of ultrasonic energy makes the bond.

Learn MoreCommon Causes of Wire Bonding Failures

Common Causes of Wire Bonding Failures . Wire bond failures comprise a major concern of any semiconductor manufacturing company. Common causes of wire bond failures include the following:. 1) Voiding in the Bonds Atomic interdiffusion between different metals is a natural phenomenon in a wirebond metallurgical system. If left unchecked, however, this can lead to voids in the bond that can

Learn MoreK&S Capillary Nomenclature | Knowledge Base Document | Inseto UK

Capillaries are high precision manufactured, with attributes specific to the wire diameter in use and bonding process parameters. Capillaries are manufactured from two main materials: Toughened Alumina. ATLAS (very high mechanical strength Alumina) The figure below describes the K&S capillary nomenclature: There are many factors to consider

Learn MoreEffect of Ceramic Capillary Parameters on Bonded ... - MDPI

4 µm Ag-5Au bonding alloy wire, and the influence of the geometric parameters of the ceramic capillary on the morphology of the alloy wire ball

Learn MoreWire Bonding Capillary (Capillaries) Market Size, Share and

09/06/2022 · The global Wire Bonding Capillary (Capillaries) market size is projected to reach multi million by 2028, in comparision to , at unexpected CAGR during 2022-2028 (Ask for Sample Report).

Learn MoreBonding Wire - an overview | ScienceDirect Topics

Smallest bonding pitch: 25 μm using 18–20 μm diameter wire.Chip–chip assembly: Bond capillary touches bond pad during second bond, making this method unsuitable for chip-tochip bonding (risk of pad damage). However, there are workarounds like the use of stand-off-stitches, basically requiring a bond-stud to place on the second pad to

Learn More89017 Capillary KH Lim Brochure - Dou Yee Enterprises

Common problem associated with copper wire bonding and bonding on NiPd plated leadframes and QFN packages are poor bondability on the 2nd bond. Dou Yee has developed the HMX Capillary with the objective to improve the bondability of the stitch bond through better coupling between the capillary and the wire during bonding. Its HMX proprietary

Learn MoreWire Bonding Tools - PECO

How to Order Solution. Products · Wire Bonding Tools; Capillary. Capillary. top. R5; P5; R6. Au wire application CC Group PCC/ECC. Selection Guide.

Learn MoreBall Bond Capillary, .375", .001 wire

Manufacturer: GAISER / COORSTEK ; Features: General purpose ball bond capillary for .001" gold wire ; Size: .001 wire, .375" tool length ; Part Number: 1572-15-

Learn MoreWirebonding Tools: Capillaries, Wedges, etc

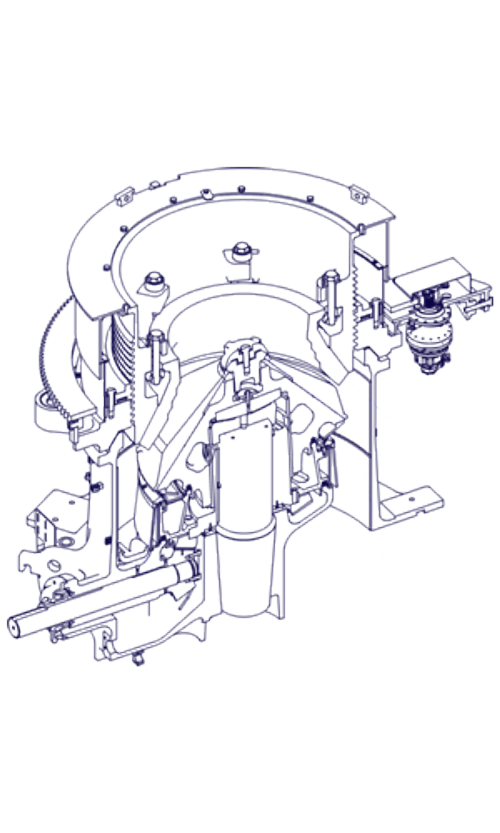

Wirebonding equipment use bonding tools known as capillaries for thermosonic ball bonding. Capillaries hold and control the bonding wire as well as form bonds from it during the ball bonding process. Capillaries are ceramic axial-symmetric tools with vertical feedholes (holes where the bonding wires are fed) through its center. Fig. 1.

Learn MoreWire bonding capillary profile and bonding process parameter

In this paper, a methodology for wire bonding parameter modeling is developed, which considers the capillary, FAB and device on silicon. The impact of capillary profile and bonding process

Learn MoreK&S - Vertical Wire Bonding Solution

The ProVertical Loop Process Enables. Vertically bonded wires per requirements - Target Wire Height & Form Angle. Minimized wire-to-wire pitch - No second bond knicking on substrate or

Learn MoreBonding Wires, Wedges and Capillaries - TPT Wire Bonder Co.KG

For Bond capillaries, various selected refined materials are available: for example, alumina, zirconia toughened alumina, and tungsten carbide. Vacuum Pickup Heavy wire wedges for challenging aluminum wire bonding applications. With high-performance cermet tips, heavy wire wedges offer excellent performance. Available in V Groove, U Groove

Learn More

Leave A Reply