High Chromium Cast Iron

For the high chromium cast iron treated at 950 °C, high volume fraction of carbide pits accelerates the wear rate significantly even though it has a similar carbide orientation as the sample

Learn MoreCN104195420A - High-chrome wear-resistant cast iron material and heat

The invention discloses a high-chrome wear-resistant cast iron material and a heat treatment method. The high-chrome wear-resistant cast iron material is prepared from iron as a main raw material, and carbon, silicon, manganese, sulphur, phosphorus, chrome, molybdenum, nickel and copper as auxiliary materials in manners of melting and casting after preparation.

Learn MoreDevelopment of High Chromium White Cast Iron Liquefaction

In this paper, high-chromium 280X29NL cast iron is reduced to 28.86 – 31% to 14 –. 15%, 1% gchach Cu is added, the chemical composition is changed and the new

Learn MoreHigh-chromium Cast Iron Market Share | Revenue And Structure

2022/9/5 · The High-chromium Cast Iron market report deals with multiple research objectives, investment plans, business strategies, import-export, and supply-demand. It provides deep

Learn MoreHigh chromium cast iron pipe | Abrasion resistant pipe

High chromium cast iron pipe is an alloy steel intended for high temperature and high pressure services. Features of High chromium cast iron pipes The late eighty`s, American technology of rare earth wear resistant steel was introduced into our country. The relevant experts researched and made many experiments.

Learn MoreAlloy data sheet high chrome white iron 25% | Penticton Foundry

The 25% Cr alloy is the most common high chrome white iron poured at Penticton Foundry. This alloy has great abrasion resistant properties

Learn MoreHigh chromium cast iron | Abrasion resistant pipe

High-chromium cast iron is a chromium-based white cast iron with a chromium content between 12% and 28%. Due to the large amount of chromium added, the M3C-type carbide in

Learn MoreMetallurgical Aspects of HIGH- CHROMIUM WHITE IRONS

the class i type d (ni-hard 4) alloy is a modified nickel-chromium iron that contains higher levels of chromium, ranging from 7 to 11% and increased levelsofnickel,rangingfrom5to7%. whereastheeutecticcarbidephaseinthe lower-alloyed nickel-chromium irons is m3c (iron carbide), which forms as a continuous network in these irons, the higher

Learn MoreAssessment on abrasiveness of high chromium cast iron material on the

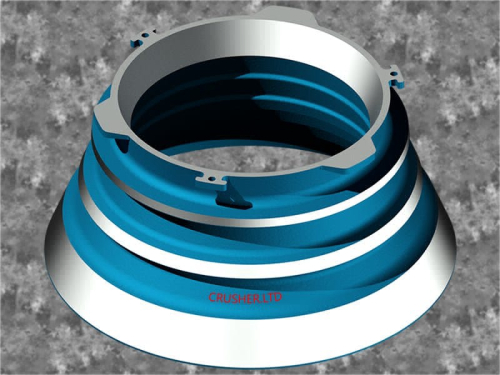

High chromium white cast iron Due to the superior abrasion and corrosion resistance, high chromium white cast irons (HCWCI) are widely applied in industrial products, especially in mining, crushing, drilling and so on. The high abrasion resistance of HCWCI is related to chromium content in the material.

Learn MoreImprovement in microstructure and wear-resistance of high chromium cast

High chromium cast iron (HCCI), containing high-volume M 7 C 3-type (M: Fe and Cr) hard carbide formed at a certain Cr/C ratio, are widely used in machinery, metallurgy, mining fields for their good properties of hardness and wear resistance [1-4].However, the severe wear caused by coarse primary carbide restricts their further utilization [5-7].

Learn MoreWear resistance of high chromium white cast iron for coal

High-chromium white cast irons are ferrous alloys containing 11-30% Cr and 1.8-3.6% C along with variable amounts of molybdenum, manganese, copper and nickel [1]

Learn MoreGeneral Corrosion Behavior of High Chromium Cast Iron in an

The effect of carbon addition on the general corrosion behavior of high-chromium cast iron (HCCI) was studied by a scanning electron microscope with energy

Learn MoreGrain refinement of 25 wt% high-chromium white cast iron by

Increasing the hardness of the high-chrome white cast iron (HCWCI), which improves the resistance to abrasion wear, is often accompanied by a deterioration

Learn MoreHigh-chromium and high-silicon cast irons

OSTI.GOV Journal Article: High-chromium and high-silicon cast irons

Learn MoreCharacterisation and machinability of high chromium hardened white cast

High chromium hardened white cast iron (HCWCI) is widely used in processes having high mechanical requirements and wear resistance but having limited toughness. Its wear resistance is directly linked to its microstructure and the addition of alloy elements [ 1 ].

Learn MoreEffect of molybdenum, vanadium, boron on mechanical

The high chromium white cast iron was produced by casting process and formed in 50 mm size of grinding balls with several compositions.

Learn MoreMicrostructure of high-chromium cast iron after etching

High-chromium cast iron is typically used for components operated in conditions characterized with intensive abrasive wear in power, mining, ceramic, cement, and aggregate supplying industries [1,

Learn MoreAS2027 Cr27 High Chromium White Cast Iron Centrifugal Cast Pipe

In February , we produce AS2027 Cr27 High Chromium White Cast Iron Centrifugal Cast pipes for our Korean customers. Centrifugal Cast Pipe 1. There are nine pieces in the early stage.The material is AS2027 Cr27.The weight of one piece is about 65kg.The wall thickness is 15mm, and the machined after annealing, the hardness is HRC38.

Learn MoreHigh Chromium Cast Iron: Part Two :: Total Materia Article

High chromium white cast irons are an important class of wear resistant materials. Their exceptional wear resistance is the result of their high carbide content, which forms along with austenite during solidification as a pro-eutectic or eutectic phase depending on alloy composition, and particularly depending upon carbon and chromium content.

Learn MoreHi-chrome Iron Alloy | Hi-Chrome Casting | Hi-Chromium Alloy

WSF can produce for you a 15% and 25% Hi-Chrome alloy iron. Typically used in applications of wear resistance and long term heat resistance are required, such as impellers, turbines, and

Learn MoreWear resistance of high chromium cast iron is the best

The configuration of the large mill roller, high chromium cast iron can avoid weaknesses, give full play to its excellent abrasion resistance, lining up more than 8 years of life. The heat treatment process of high chromium cast iron is usually heated to 950~1000 DEG C, and then quenched at room temperature for 200~260 C after quenching.

Learn MoreDevelopment Of Technology To Increase Resistance Of High

Of Technology To Increase Resistance Of High Chromium Cast Iron of stable structural high chromium cast iron and high friction of

Learn MoreHigh Chromium Cast Iron factory, Buy good quality High Chromium Cast

EN-GJLA-XCr14 Swing Arm JIS High Chromium Cast IronContact Now Get Best Price. EN-GJLA-XCr14 Swing Arm JIS High Chromium Cast Iron Since 2003, Wuxi LT New Material Co., Ltd. (LT) has been manufacturing excellent quality cast parts for pumps, valves, railway vehicles, construction Read More. 2021-08-05 08:28:46.

Learn MoreGlobal High-chromium Cast Iron Market Report 2022, Market Size, Growth

2.1 Product Overview and Scope of High-chromium Cast Iron; 2.2 High-chromium Cast Iron Segment by Type . 2.2.1 Global High-chromium Cast Iron Revenue (USD Million) and Growth Rate (%) Comparison by Type (2016- )

Learn MoreHeat Treatment in High Chromium White Cast Iron Ti Alloy

2/3 · High chromium cast iron is one of the wear resistant materials used in a variety of applications where stability in an aggressive environmental is a principal requirement. These applications include slurry pumps, brick dies, several pieces of mine drilling equipment, rock machining equipment, and similar areas [ 1, 2 ].

Learn MorePDF) Structure of High-Chromium Cast Iron - ResearchGate

Structure of High-Chromium Cast Iron T. S. Sko blo, O. Yu. Klo chko, and E. L. Belkin Vasilenko K harkov N ational Agricultural University, Kharkov, Uk raine Abstract —Mathematical analysis permits

Learn MorePDF Metallurgical Aspects of HIGH- CHROMIUM WHITE IRONS - foundry-planet.comPDF

Chromium is included in these alloys,atlevels from1.4 to4%to ensure that the irons solidify carbidic (i.e., to counteract the graphitizingeffectofnickel). Typical microstructure of class I type A nickel-chromium white cast iron.

Learn MoreHigh chromium cast irons: destabilized-subcritical secondary

Fu, J. Peng, B. Xiao, Effect of heat treatment on microstructure and mechanical properties of a Ti-bearing hypereutectic high chromium white cast iron

Learn MoreHigh-chromium Cast Iron Market Research: Global Status & Forecast by

Exact matches only . Search in title. Search in title

Learn MoreDoes chromite have iron in it? Explained by FAQ Blog

What are 3 uses for iron? Uses of iron Iron is used to make alloy steels like carbon steels with additives such as nickel, chromium, vanadium, tungsten, and manganese. These are used to make bridges, electricity pylons, bicycle chains, cutting tools and rifle barrels. Cast iron contains 3-5% carbon. It is used for pipes, valves, and pumps.

Learn MoreHigh chromium white iron cast alloy ASTM A532 15/3CrMo or 25%Cr

High chrome white iron cast alloy's superior wear resistance is due primarily to a high volume fraction of very hard, well-dispersed primary and secondary carbides in a matrix of martensite. The high chromium content provides good resistance in corrosive environments and good oxidation resistance. COMPOSITION C % 2.0 - 3.5 Mn % - 1.5 max.

Learn More

Leave A Reply