AISI 4140 Chrome-Molybdenum High Tensile Steel - AZoM

Chromium, Cr, 0.80 - 1.10 % ; Iron, Fe, 96.785 - 97.77 % (As remainder) ; Manganese, Mn, 0.75 - 1.0 % ; Molybdenum, Mo, 0.15 - 0.25 %.

Learn MorePhysical and Chemical Properties of Hard Chrome - U.S

Hard chrome has a very low coefficient of friction. Applying a surface finish, like hard chrome, would greatly reduce friction, therefore increasing the service life and performance of the parts.

Learn MoreChromes | Continental Alloys

Commonly called chrome, the alloy referred to here is actually chromium. Chromium is added to steel in small quantities to improve strength, corrosion resistance and response to heat

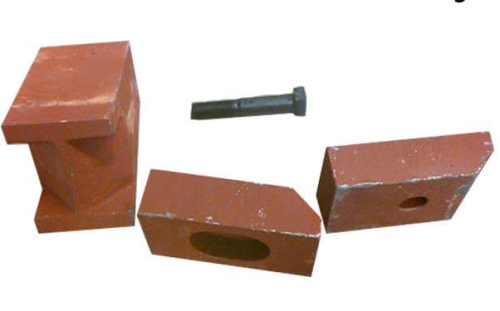

Learn MoreHigh Chrome Bricks - RongSheng Kiln Refractory, Inc

The main raw material to manufacture high chrome refractory brick is sintered magnesia and chromite. Purity magnesia raw material to be as high as possible, the requirements of the chemical composition of chromite is: Cr2O3: 30 ~ 45%, CaO1.0 ~ 1.5%.

Learn MoreNickel Chrome Alloys - Nickel Alloys .Net

Nickel/chromium alloys containing more than 30% chromium have a two phase structure which consists of a -chromium and γ-nickel. The a -chromium phase brittle and hence the alloy decreases in ductility with increasing chromium content. Properties for some binary alloys are given in table 2.

Learn MoreHC27 HIGH CHROME WHITE IRON

HC27 is a modified High Chromium White Iron developed to provide the highest degree of toughness while retaining excellent abrasion resistance. This.

Learn MoreHigh carbon-chromium low alloy steel type CR - Ideal-tek

General notes: » chrome alloy tool steel (Material number 1.3505, 100Cr6, AISI 52100). » magnetizable. » hardened by heat treatment, max. hardness 68 HRC.

Learn MoreWear resistance of high chromium white cast iron for coal

High chromium white cast iron alloy used in coal grinding components is a material that may present different wear resistance depending on the thermal treatment

Learn MoreCN104195420A - High-chrome wear-resistant cast iron

The high-chrome wear-resistant cast iron material is prepared from iron as a main raw material, and carbon, silicon, manganese, sulphur, phosphorus, chrome, molybdenum, nickel and

Learn MoreChromium - Wikipedia

Chromium is a chemical element with the symbol Cr and atomic number 24. It is the first element in group 6.It is a steely-grey, lustrous, hard, and brittle transition metal. Chromium metal is valued for its high corrosion resistance and hardness.A major development in steel production was the discovery that steel could be made highly resistant to corrosion and discoloration by adding metallic

Learn MoreCN104195420A - High-chrome wear-resistant cast iron material and heat

The high-chrome wear-resistant cast iron material is prepared from iron as a main raw material, and carbon, silicon, manganese, sulphur, phosphorus, chrome, molybdenum, nickel and copper as

Learn Morehigh chrome stainless steel - Steel Material Supplier

It has a microstructurethat contains an addition of Nitrogen, Nickel, and Manganese. The construction of austenitic chrome steel is similar as what you would find in common steel. But solely in a much larger temperature giving it formability and weldability.

Learn MoreIntroduction and application of high chromium materials

12/20 · Application of high chromium cast iron in cement mill. The cement grinding roller liner of mn-al composite high chromium cast iron is not ideal for the hardenability and wear

Learn MoreMicrostructural Characteristics and Mechanical Properties of

Changing in chemical composition and heat treatment carried Figure 1: High chromium iron microstructures in the as-cast; (a) with austenitic matrix

Learn MoreChemical and structural characterization of thermally degraded black chrome

The U.S. Department of Energy's Office of Scientific and Technical Information

Learn MoreWear Resistant Irons - BAS Castings

Wear Resistant Irons are also referred to as High Chrome Alloys, Abrasion Resistant Irons, White Irons and Ni hard. This family of materials has been

Learn MoreASTM A532 Class I Type A | Ni-Hard 1 High Chrome White Iron

Nickel-Chrome-High Carbon Alloy This material may also be called Ni-Hard 1. Ni-Hard 1 is an abrasion resistant material used in applications where impact is also a concern as the wear mechanism. Ni-Hard 1 should also be considered if there are low or medium dynamic stresses.

Learn MoreHigh Chromium Cast Iron: Part One :: Total Materia Article

High-chromium irons have good mechanical properties, high hardness in a cast state, low fluctuation of hardness when properties change. High-chromium irons almost don’t concede in fluidity to regular gray cast iron that allows using parts sufficiently difficult form directly after casting without the following machining.

Learn MoreCN103924164A - High chrome alloy steel material and

The invention discloses a high chrome alloy steel material and a preparation method thereof. The high chrome alloy steel material contains the following chemical elements by mass

Learn MoreHigh Chromium Cast Iron: Part Two :: Total Materia Article

High chromium white cast irons are an important class of wear resistant materials. Their exceptional wear resistance is the result of their high carbide content, which forms along with austenite during solidification as a pro-eutectic or eutectic phase depending on alloy composition, and particularly depending upon carbon and chromium content.

Learn MoreHigh Chrome Slurry Pump Materials - Tobee Pump

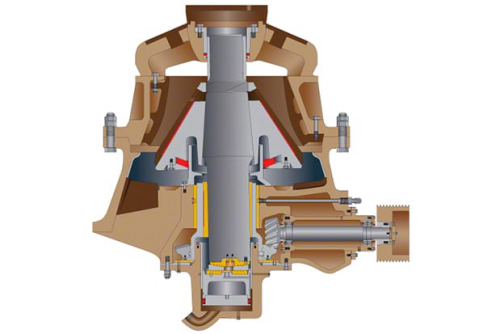

High Chrome A05 Alloy The microstructure of High chrome alloy A05 (27 Cr) shown in Figure 1(a) consists of hard eutectic chromium carbides in a fully hardened martensitic matrix. The material is covered by a number of different Internationally recognised standards including: ISO 21988 Grade 25Cr, AS 2027 Grade 27Cr; BS 4844 Grade 3D and ASTM

Learn MoreAlloy Data Sheet - Tough 25 High Chrome White Iron

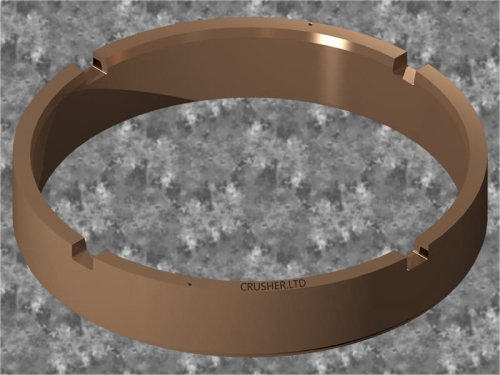

25% Chrome Tough Alloy. This alloy maintains the abrasion resistance of the 25% chrome alloy with increased toughness. This alloy is used for thicker section castings exposed to a high impact environment, such as in mining and crushing and in the Alberta Oil Sands . Castings poured with this alloy can be machined, but not drilled or tapped.

Learn MoreAlloy data sheet high chrome white iron 25% | Penticton

1/13 · ASTM A532 Class III Type A. The 25% Cr alloy is the most common high chrome white iron poured at Penticton Foundry. This alloy has great abrasion resistant properties

Learn MoreHigh-chrome - Duromax® | Magotteaux

Superior grinding performance High-Chrome media combining a martensitic structure with hard chrome carbides provides the optimum wear resistance against abrasion and corrosion. Our strong expertise is enabling us to select the right alloy to fit your application and minimize the costs. Steady milling conditions due to low wear rate Constant hardness of all grinding media

Learn MoreCorrosion of phosphate added high-chrome refractory materials in an

Chromium oxide is the main component of the phosphate added high-chrome refractory. Spinel solid solutions were the main reaction products at the interface between the high-chrome refractory and the slag ( Table 7 ), thus confirming the formation of spinel solid solutions. Anorthite was the crystal phase in the slag ( Table 6 ).

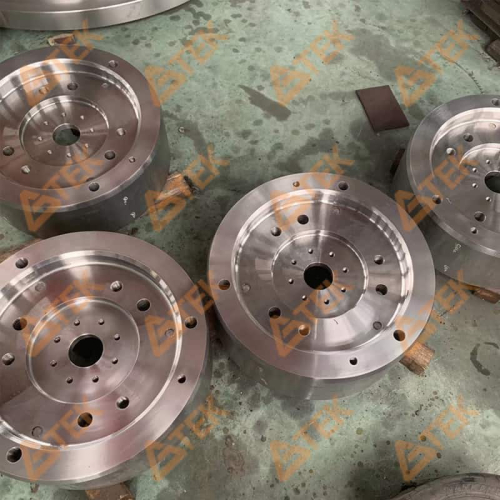

Learn MoreHigh Chrome Steel Rolls - Expert of Mill Rolls

High Chrome Steel Rolls HiCr Steel is characterized by excellent fire crack resistance and very good oxidation behaviour at rolling temperature. Very good wear resistance and constant material properties throughout the shell layer. HiCr Steel is manufactured by horizontal spin casting.

Learn MoreHIGH-CHROMIUM ALLOY - ASM International

Table 1 shows the basic chemical composition of Alloy 31 compared with other alloys that mit- igate aqueous corrosion. It has half the nickel con-.

Learn MoreChrome core 13 Steel Chemical composition, Metal Properties, Datasheet, Chrome core 13 material

Physical Properties of steel grade Chrome core 13. Temperature. (°C) Modulus of elasticity. (GPa) Mean coefficient of thermal expansion 10-6/ (°C) between 20 (°C) and. Thermal conductivity. (W/m·°C)

Learn MoreThe Introduction of High Chrome Grinding Media Balls | Grinding

High Chrome Alloy Grinding Media Balls High chromium white cast iron grinding balls are also called high chromium alloy casting balls.Most of the wear-resistant materials enterprise use medium frequency electric furnace through the melting of high-quality scrap steel and chromium alloy materials after reasonable matching.What is more,they also use grinding ball metal

Learn MorePhase diagram calculation of high chromium cast irons and

According to the characteristics of high chromium cast iron, if its chemical composition can be controlled and proper heat treatment be adopted, the abrasion

Learn MoreHigh Chrome Cast Grinding Balls

cement plant use wear-resistant High Chrome Cast Grinding Balls We are one of the largest factory specialized in producing Forging Grinding Media Ball, Rolling Grinding Media Balland Casting Grinding Media Ball in China. It was founded in 1988, located in Zhangqiu City, Shandong Province, China. Annual Production Capacity is 50,000 metric ton.

Learn More

Leave A Reply