Cement Kilns: Grate Coolers

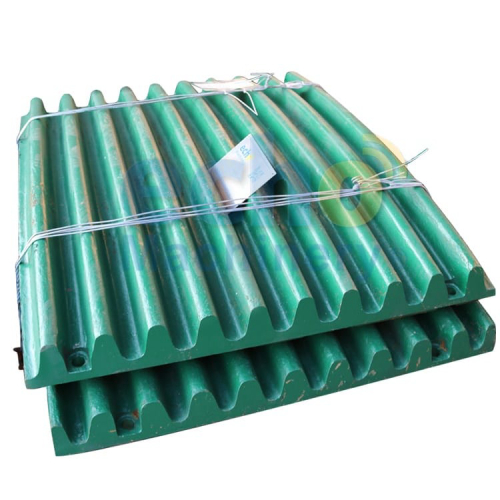

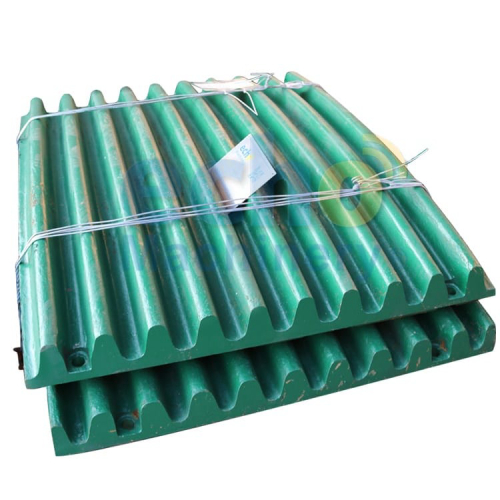

The first form of grate cooler used on British kilns was the Bucket Grate. The cooler was built into a greatly-enlarged kiln hood, with length about 1.9 times the kiln diameter, and width 15% greater than the length. A concave grate-plate occupied the entire base, with a pressurisation chamber below.

Learn MoreIron ore pelletisation plant, using the grate kiln process

Grate kiln plants are economical and suited for medium scale production. GoodRich offers iron ore pelletisation plants from a reputed manufacturer in China, based on the grate kiln technology. The plants are available in capacities from 100,000 tons to 1,200,000 tons per annum. The Chinese company has already supplied 8 pellet plants in India.

Learn MorePDF Pelletization SolutionsPDF

The Grate-Kiln induration machine is composed of three separate pieces of equipment; the Traveling Grate, the Rotary Kiln, and the Annular Cooler. Independent variable speed control of drying/preheating, induration, and cooling allows process flexibility to adjust to changes in concentrate feed.

Learn MoreGrate Cooler | Clinker Cooler, Cement Cooler | Cement Plant

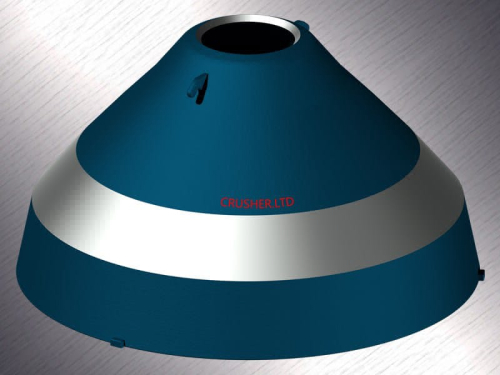

Grate cooler. Production Capacity: 600~10000 t/d. Heat recovery rate: ≥72%. Application: cement, silicate products, new building materials, etc. . The grate cooler is a quenching type cement cooler apply for the cement manufacturing plant. According to the movement mode of the grate, the grate cooler can be divided into three

Learn MorePelletizing Process

2011. 1. 6. · Grate-Kiln-Cooler process allows independent operation adjustment of grate, kiln and cooler, which enables the operators ; a) to, easily and without any risk, decrease and increase the rate of pellet production. b) to overcome radical changes in the characteristics of iron ore materials fed to the

Learn Moregrate kiln - English definition, grammar, pronunciation, synonyms and

For existing plants, both straight grate and grate kiln systems, it is difficult to obtain the operating conditions necessary to suit an SCR reactor. EurLex-2 Bypass dust: Dust discarded from the bypass systems of the suspension preheater, precalciner and grate preheater kilns , consisting of fully calcined, kiln feed material.

Learn Moregrate kiln - English definition, grammar, pronunciation, synonyms

For existing plants, both straight grate and grate kiln systems, it is difficult to obtain the operating conditions necessary to suit an SCR reactor. EurLex-2 Bypass dust: Dust discarded from the bypass systems of the suspension preheater, precalciner and grate preheater kilns , consisting of fully calcined, kiln feed material.

Learn MoreGrate Kiln Stock Photos, Pictures & Royalty-Free Images - iStock

Search from Grate Kiln stock photos, pictures and royalty-free images from iStock. Find high-quality stock photos that you won't find anywhere else.

Learn MoreGrate-Kiln System for iron ore pelletizing - DirectIndustry

The kiln is a single chamber with an open feed end connected by housing to the grates preheat furnace Through this connection is the inflow of material to the kiln and outflow of kiln gas to the preheat furnace. The kiln's discharge end is open and connected to the cooler by a firing hood. Through the firing hood, pellets flow from the kiln to

Learn MoreCONTRIBUTIONS TO THE TECHNOLOGY COMPARISON BETWEEN STRAIGHT GRATE AND GRATE-KILN

2020. 4. 6. · Today, grate-kiln systems are built and operated in units with up to 6 million t/a capacity (Bahrain Steel) , whereas straight grates produce up to 8.5 million t/a in individual strands (Samarco 4). The biggest pelletizing complexes are situated in

Learn MoreGrate kiln system - Big Chemical Encyclopedia

Grate kiln system Work to test the feasibility of the grate-kiln system for the hardening of iron ore pellets began at the Allis-Chalmers pilot plant at Carrollville near Milwaukee, Wisconsin, USA, in the 1950s. The first commercial plant started-up in the mid 1960s at the Humboldt Mining Co., in Michigan, USA [Section 13.3, Ref 16]. The exhaust gases are generally discharged into dust and

Learn MoreOutotec to add to Grate Kiln iron ore pellet reference list with

Outotec has signed an agreement for the delivery of engineering and key equipment for an iron ore Grate Kiln pellet plant to Vulcan Pelletizing LLC. The plant is located in the industrial port of Sohar, the Sultanate of Oman, with the value of the order being approximately €33 million ($35 million). The pellet plant will supply pellets

Learn Morekiln iron–ore pellet induration process - PDF Free Download

GRATE/KILN PELLET INDURATION The Allis-Chalmers grate/kiln process employs a furnace with a moving grate for drying and preheating the J.A. THURLBY is Principal Research Scientist, Division of Mineral Engineering, Commonwealth Scientific and Industrial Research Organisation, Clayton, Victoria, Australia. Manuscript submitted June 24, 1986.

Learn MoreGrate-Kiln Operations for Better Pellet Quality

Capacities range from 7.1 metric tonne/ hour (7 long ton/hour) to 508 metric tonne/hour (500 long ton/hour). In testing the pellet plant feed materials from each of the operations, the first test series included firing of fresh plant green balls in the pot-grate and batch rotary kiln in order to avoid green ball degradation.

Learn Moreto supply large-scale grate-kiln pellet plant to India - SteelOrbis

Finland-based global engineering and technology company Outotec Corporation has announced that it will supply a large-scale grate-kiln pellet plant to an Indian customer in Odisha. The value of the order is estimated to be in the range of €30-40 million. According to the statement, the grate-kiln plant with an annual production capacity

Learn MoreGrate Cooler in Cement Plant | Cement Clinker Cooler for Sale

2022. 9. 8. · The performance of the grate cooler will directly affect the production efficiency, energy consumption, and clinker quality of the kiln system. The grate cooler belongs to the family of air quench cooler (AQC). The clinker fed into the grate cooler can be quenched from 1300-1400 ℃ to below 100 ℃ in just a few minutes.

Learn MorePelletization Solutions

2020. 1. 16. · Grate-Kiln system Consistent pellet quality, lowest operating costs The Grate-Kiln induration machine is composed of three separate pieces of equipment; the Traveling Grate,

Learn MoreUnderstanding Pellets and Pellet Plant Operations - IspatGuru

Grate-kiln systems can be designed for production capacities up to 6 million tons per year per line. These systems are used by many plants. Pelletizing processes are being improved constantly. The production of self-fluxing pellets is an example of an innovation that has been accepted on a commercial scale and has led to major advances in blast

Learn MoreIron Ore Pelletizing Grate-Kiln System Brochure - DirectIndustry

Energy efficiency The Grate-Kiln® induration machine is composed of three separate process pieces of equipment. The traveling grate is used primarily to dry and preheat green balls for feeding into the rotary kiln, where they are indurated. Once the green balls are made they are spread out evenly across the grate.

Learn MoreGrate Kiln For Sale – Grate Kiln System | AGICO Grate Kiln

The grate kiln system consists of three independent machines: traveling grate, rotary kiln, and annular cooler. Operators can separately control the running speed of the three devices. It

Learn MoreEnergy and exergy analyses of a mixed fuel-fired grate–kiln for

2011. 5. 1. · The local exergy destruction rate of grate, kiln, and cooler is 74.2%, 14.1%, and 7.7% respectively. And the exergy efficiency in the GKC plant and its major components is not significantly influenced by variation of the reference environment temperature. So, these indicate the grate is the least efficient one in the three major components.

Learn MoreGrate Kiln - China Factory, Suppliers, Manufacturers

Grate Kiln Manufacturers, Factory, Suppliers From China, We give priority to quality and customer pleasure and for this we follow stringent excellent control measures. We've got in-house testing facilities where our items are tested on every single aspect at different processing stages. Owning to latest technologies, we facilitate our clients with custom made creation facility.

Learn MoreOverall comparison of straight grate (SG) and grate-kiln (GK

Schematic of the two principle pelletizing processes: (a) straight grate pelletizing process (Mourão, ); (b) grate-kiln pelletizing process ( , ) Currently, the existing

Learn MoreGrate-Kiln System Operation - Metallurgist & Mineral Processing Engineer

The Humboldt and its Grate-Kiln System Operation on crude ore is a mixture of cherty specular hematite and magnetite, with minor amounts of martite and sericite. Mineralization varies from coarse to extremely fine grained. The overburden varies from zero to 50 ft. The ore body is approximately 1300 ft. long and varies in thickness from 250-400′.

Learn MoreGrate-Kiln System for iron ore pelletizing - Automation

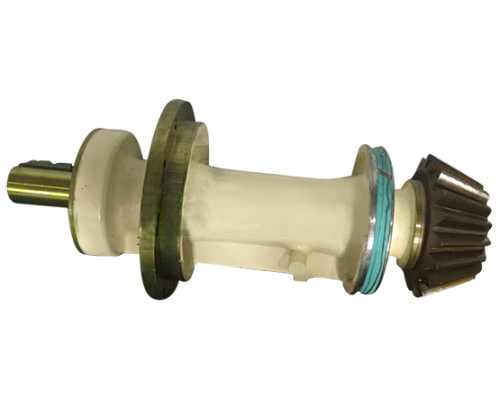

Kiln drive components Equipment description Grate The traveling grate is a conveyor that transports balled iron ore concentrate through cross-flow processing zones. The conveying

Learn MoreCement kiln - Wikipedia

Cement kilns are used for the pyroprocessing stage of manufacture of portland and other types of hydraulic In this case, the water content of the pellets is 17-20%. Grate preheaters were most popular in the 1950s and 60s, when a typical system would have a grate 28 m long and 4 m wide, and a rotary kiln of 3.9 x 60 m, making 1050 tonnes per

Learn MoreCombustion grate for all types of waste, solid and sludgy wastes

The grate area is very big and the supply with combustion air inside the combustible materials is optimal. The arrangement of the combustion shingles is designed for a safe discharge of the sludge via the combustion grate. The combustion air cools the grate, absorbs the energy and dries the sludge even faster on the first stages by preheating.

Learn MoreGrate-Kiln pellet plant Archives - International Mining

2021. 4. 8. · The first grate kiln pellet plant is currently being installed at the same location by Outotec and JSOL. The value of the most recent order is around €30 million ($33.2

Learn Moreto supply large-scale grate-kiln pellet plant to India

2021. 4. 9. · Finland-based global engineering and technology company Outotec Corporation has announced that it will supply a large-scale grate-kiln pellet plant to an Indian customer in Odisha. The value of the order is estimated to be in the range of €30-40 million. According to the statement, the grate-kiln plant with an annual production capacity of six

Learn Moregrate-kiln furnace | metallurgy | Britannica

Other articles where grate-kiln furnace is discussed: iron processing: Pelletizing: This was followed by the grate-kiln and the traveling grate, which together account for more than 90

Learn MoreGrate Kiln Tech's 94.9% Vanadium Extraction Unlocks Value For AVL

Completion of pilot testing has confirmed that well-established Grate Kiln technology can be used for vanadium extraction at Australian Vanadium's namesake project. Process optimisation by roasting a concentrate representative of average early years mine production has confirmed combined vanadium roast/leach extractions of up to 94.9 per cent.

Learn More

Leave A Reply